|

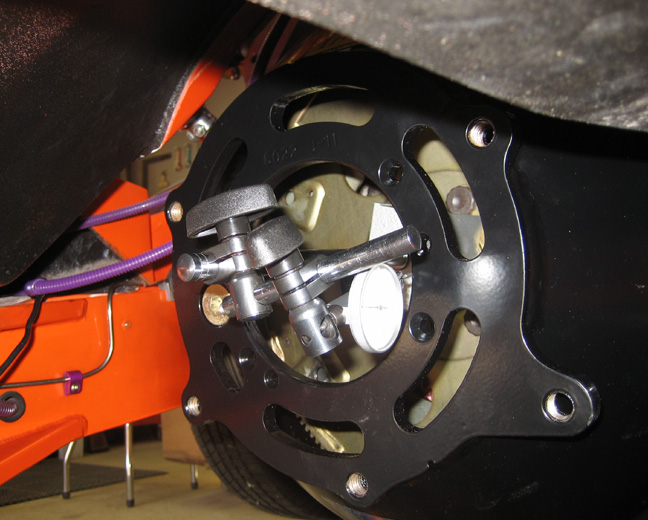

The next thing to do was to bolt up the scatter shield and then check

to see if the large center hole where the trans locates is within .005"

of center. To do this I thought I'd try bumping the motor over with my

starter and remote starter switch. In order to have the starter move the

engine I would need a flywheel so I bolted on my old one. This didn't

work well because when I engaged the starter, no mater how quick I was

on the button the indicator moved. The starter was too violent for this

delicate work so on to plan B.

|

|

|

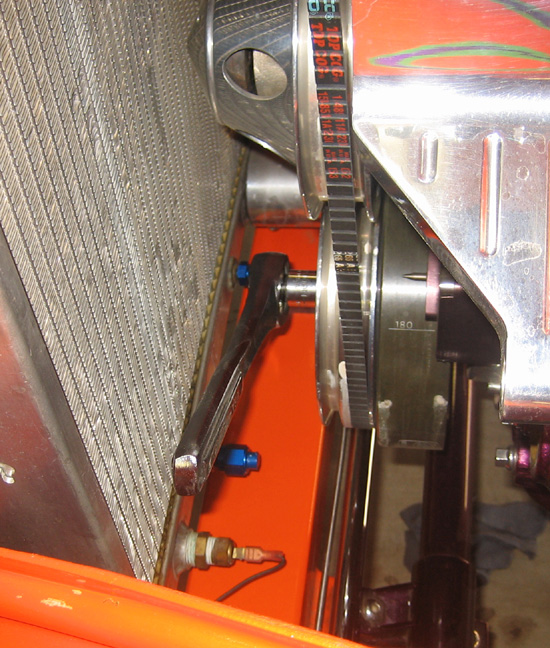

I decided to pull all the spark plugs out and crank over

the motor by hand. You can see all the plug wires dangling if you look

close. And those spark plugs looked pretty bad because they've been in

there for a long time. It will do me good to replace them.

|

|

|

I used my 1/2" drive ratchet and cranked the motor over a small amount,

then got back under the car and looked at the indicator. What I wanted

to do was rotate the engine 90 degrees and then note the reading. If it

wasn't enough I'd move it a little more till I had it right and then

repeat the process all the way around. This worked pretty good and the

hole on the scatter shield was in specification. I was aloud .005" off

center or .010" total indicator reading (TIR) and mine was at .007" TIR

so I was in good shape. If it was more than .005" off center then you

would have to buy off-set dowel pins and then repeat this process again

till you were in spec. Finally something went pretty easy for a change.

|

|

|

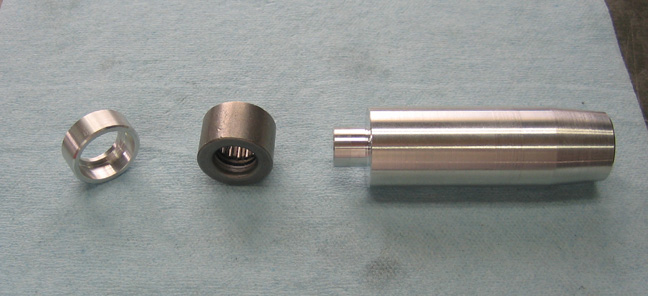

Now that the scatter shield and clutch were ready to bolt on I decided

to install my new roller pilot bearing before I reinstalled the

flywheel. I figured with the flywheel out of the way, it should make the

bearing install that much easier. The paper work said to make sure that

the end of the pilot bearing didn't go in to far and should be flush

with the end of the crankshaft. To make sure I didn't end up going to

far I measured the depth of the pilot bearing hole and it was .400"

deeper than the bearing. I didn't want to over-shoot so I made a couple

of things to help me out. The piece on the right is my installation tool

and it's made out of aluminum so it doesn't damage the bearing. The ring

on the left is also made out of aluminum and is .005" smaller than the

bearing O.D. All this is insurance so I don't install the bearing to

deep. The ring measures at .400" thick and notice the recess in the I.D.

which is clearance in case I have to use a puller to get the bearing out

someday. This way I'll have room for it.

|

|

|

|

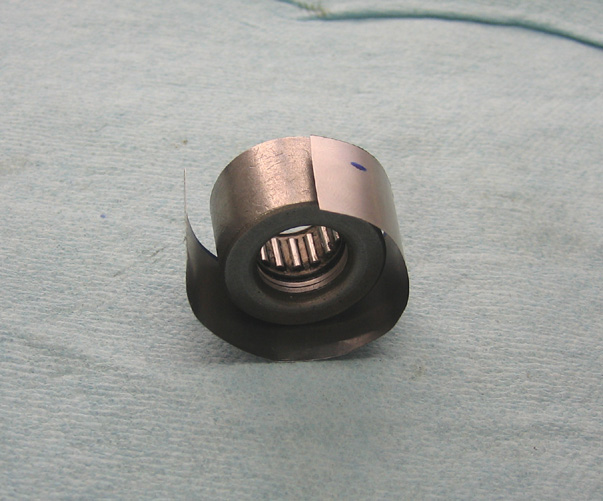

Here is how it will look when I start to install the bearing. It should

be pretty easy because all you do is hammer on the end of the tool till

the bearing and ring bottom out and then your done. Once I placed the

ring inside the pilot bearing hole and was ready to press in the

bearing, things went down hill. The bearing fell inside the hole and

went all the way down to the ring. What the hell?? Sometimes I wonder

how places stay in business. Turns out the bearing is the right size but

not the hole in the crankshaft. After measuring I found out the hole is

about .003" oversize which means no press fit....which means I'm in

trouble....again! Can't anything be easy? I'm thinking there are a few

ways to fix this - one being a new crankshaft but would mean I would

have to pull the engine out and completely rebuild it. The heck with

that!! Another way would be to increase the size of the bearing which

means making a new one out of oil-light bronze (which is what most of

them are made out of). The problem with making a new one is with the

warranty from Hurst Driveline. If you don't use all of their supplied

parts then you void the warranty.

It would be nice if I could increase the size of the existing bearing

so it would work but how do you do that?

|

|

|

This is what I came up with to increase the O.D. of the bearing, shim

stock. I figured out that I needed .003" shim material which would

increase the O.D. by a total of .006". This should be just the right

amount of press fit which is .002" in case you were wondering. I don't

know if this will work but it sure beats the hell out of buying a new

crankshaft.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

|

|

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53 |

|

54

55

56

57

58

59

60

61

62

63 |