|

I made this sub-plate (again out of aluminum) to attach the trim

plate to and it has two 10-32 threads (blue area). The sub-plate is

screwed to the toe board using riv-nuts which is under the carpet. If

you look close you can see the brake pedal to the right and the shinny

stuff is insulation.

|

|

|

|

This should give you a better idea of how the outer trim

piece will be attached to the sub-plate. I had all kinds of trouble

installing this because I worked around the pedals and carpet. Plus my

riv-nut gun couldn't get into this tight area without it binding and

when I squeezed the trigger, it ended up breaking the 8-32 threaded rod.

It took me a long time to get that removed so I moved up to the 10-32

size after that to which I had even more trouble. Let's just say it

wasn't a good day.

|

|

|

Here is what it looks like with the trim piece installed. I had to cut

the rubber a couple of times because it was binding against the clutch

pedal but it seems to work good now. If you were wondering why I didn't

space the screws evenly it's because the upper one is right against the

top of the opening in the toe board where the cutout is. If I were to

place it any higher, I would have had to remove the pedals again and I

didn't really want to do that. I need to think about what to do for

pedal pads here next.

|

|

|

This new fitting is for my oil pressure line which had broken while

taking it out months ago. It fits a 1/4" diameter plastic line which is

larger than normal because most mechanical oil pressure gages use 1/8"

diameter. The reason for the larger line is because it's much more

sensitive and will give you a quicker reading. On the other hand it can

be scary to see exactly what your oil pressure is really doing.

|

|

|

Here is the new fitting and line reattached. I'm not sure if I like how

it's bent now because I had a 90 degree fitting that went into the

engine block before. The reason I don't have the other fitting anymore

is because it would hit the scatter shield and backing plate so this is

a work around. I may have to make a different fitting or something

because I'm not sure how this will hold up.

|

|

|

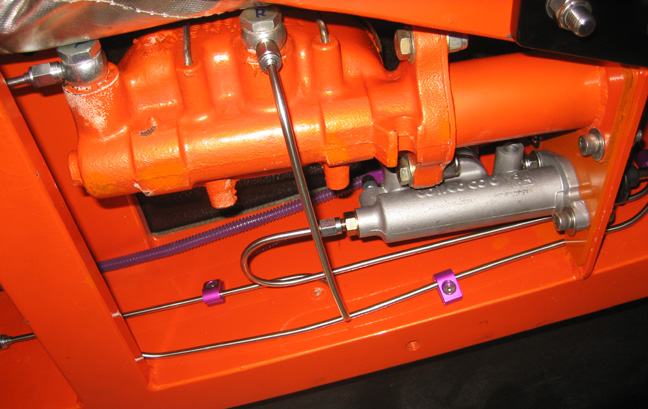

Here are the finished brake and clutch lines in place. I still have to

bleed the brakes but the master has had the bench treatment already. If

things go as good as the clutch went, the brakes shouldn't be a problem

but refilling the master cylinder will be a challenge.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

|

|

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53 |

|

54

55

56

57

58

59

60

61

62

63 |