I had some leftover undercoating so I used some here... but I didn't

spray it on. What I did was spray the undercoating into a small cup and

then I brushed it on. It doesn't have the same texture like the

surrounding area but it's protected now. This stuff smells really bad

when it's wet so I'm glad it covered in one coat.

|

|

|

This was left on my doorstep the other day and I was lucky that

everything I ordered was still in the box. It makes me wonder how this

happens because it seems like the bigger the box, the more beat-up it

gets. And if you're wondering if it was open on the end, yes it was.

|

|

|

|

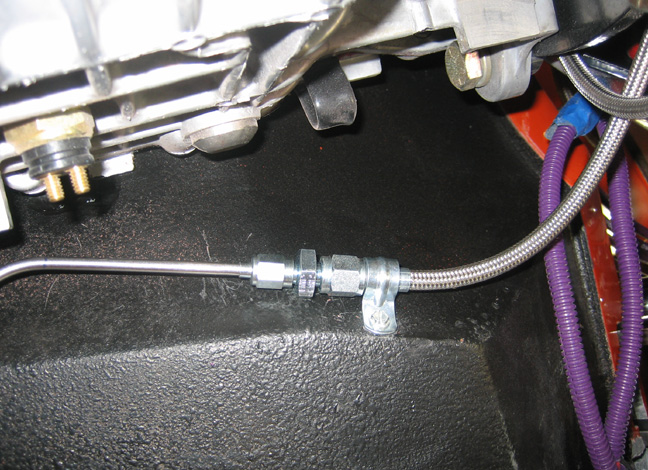

Here is one of the things that was in the box. It's a -3 to a -4 AN

adapter which I needed for my hydraulic throw out bearing line. Once I

had the new hard line bent with the -3 fitting installed, I noticed that

I the bearing line had a -4 so this will connect the two together.

|

|

|

I mounted the line on my trans tunnel which should be out

of the way of my exhaust. I also put a small piece of rubber between the

clamp and fitting so it wouldn't be metal-to-metal. The last thing I

want is a leak here so the rubber should help.

|

|

|

|

While I was in clutch mode, I remember reading about not letting the

throw out bearing overtravel. If the bearing were to overtravel it might

cause the o-ring inside to be damaged which could result in a leak. The

only way to fix this leak would be to remove the hydraulic bearing and

replace the o-ring.

What I came up with was pretty simple but should work. I drilled

through my chassis and used a piece of 3/8 all-thread with a nut on each

side for adjustment. I plan on putting a cap on the end of the threaded

piece with a softer surface instead of the solid metal one that you see

here. The reason for the softer surface is because when the pedal comes

in contact with the threaded piece, it makes a metal-to-metal noise that

I don't want. Once I have that made I'll show you more about it.

You'll also notice that I placed a clamp on the wiring loom. This

clamp will hold the loom out of way because the clutch pedal comes very

close to it. I was thinking that I may need to relocate these wires but

after installing the clamp I'm good to go. To hold the clamp in place is

a riv-nut with 8-32 threads.

|

|

|

I was wondering what I was going to do with my trans temp gage now that

the automatic is gone. But after looking around I found a place for the

gage on the new transmission. I used the drain plug hole (which required

an adapter that I happen to have) so it was an easy deal. I don't know

if you're suppose to use the drain for this but after looking inside for

something in the way, it looked nice and clear so it should work. On the

other hand, I have no idea what the normal operating temp for this trans

should be so I'll have to find that out from the manufacture.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

|

|

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53 |

|

54

55

56

57

58

59

60

61

62

63 |