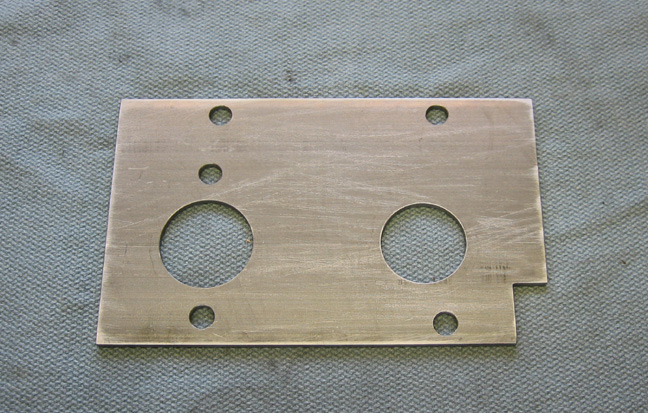

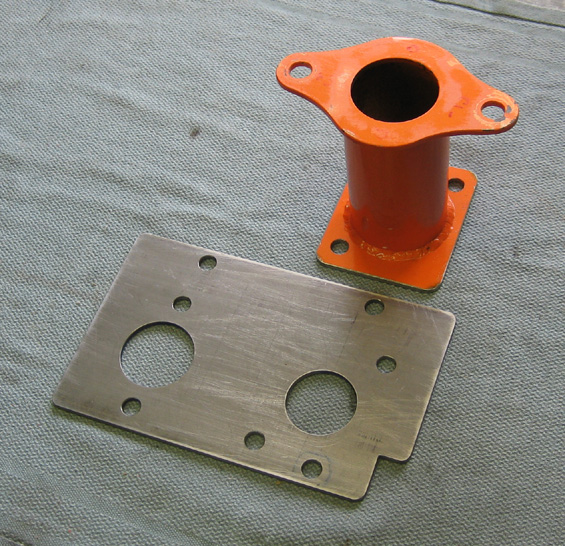

| Here is the adapter plate that I came up with. It's made

out of 1/8" steel plate and will be held on with a few bolts. The clutch

master will mount directly to this plate (on the left) and bolt up

through the two 11/32" holes at the lower left with the larger hole

having .003" clearance to locate the master just right.

The top two holes along with the lower right one are 11/32" diameter

and have the same bolt pattern as the bracket from the previous page

(which are clearance for a 5/16" bolt) but the lower left is going to

have a problem. I knew this while I was making it and it will end up

being a half-a-hole off. I'll need to modify the original 1/4" bracket

so I can use this new hole.

On the right is a clearance hole for the pushrod to pass through but

I'm not sure how I'm going to mount the brake master....yet.

|

|

|

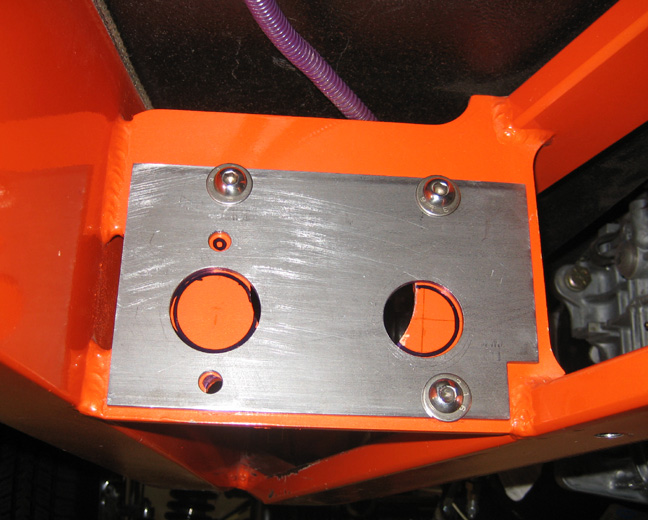

Here you can see how the bottom left hole doesn't line up. It will be a

quick fix with a carbide burr and my Dermal so that won't be a problem.

I've also laid out where I need to do some cutting and drilling.

|

|

|

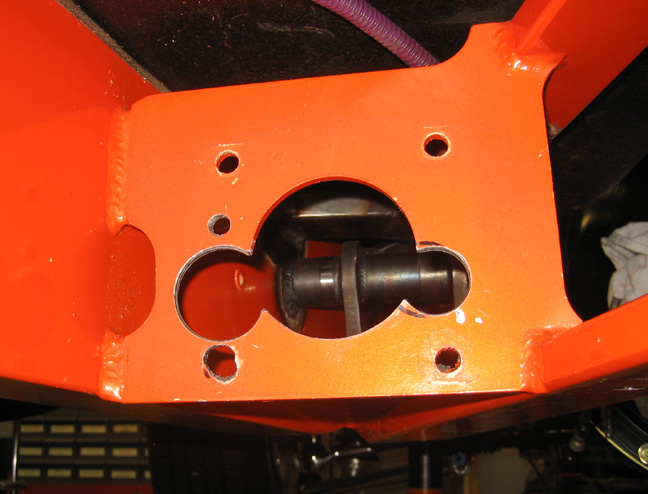

I used a 1 1/2" hole saw on the left and a one inch on the right. And

you can see I drilled one new 11/32 hole and elongated the bottom left

hole. The reason I went with a 1 1/2" hole is because the clutch master

has a rubber boot that needed clearance so I could still use it. The

other side is just clearance which is why I went with the smaller size.

|

|

|

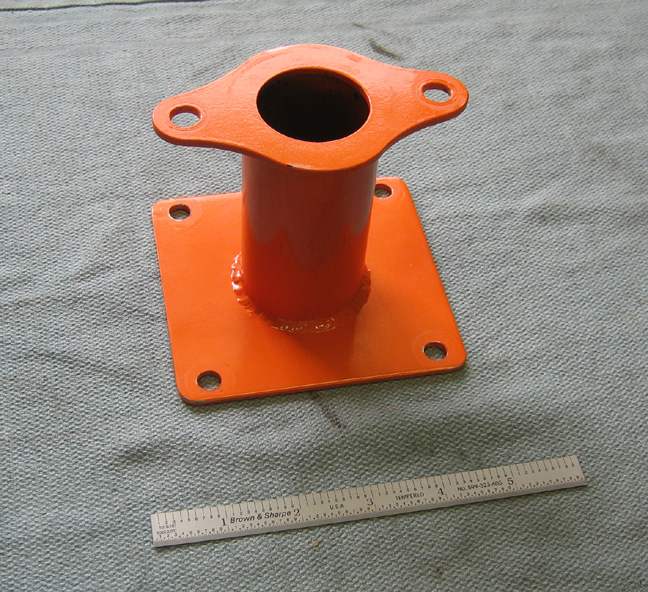

I finally came up with an idea for mounting the brake master. I thought

about cutting off the square part and then welding the tube portion to

the new adapter plate. After looking at it though, the tube would be in

the way of one bolt holes and wouldn't work so I decided to modify the

square plate instead.

|

|

|

The large square plate on the old adapter is now a smaller rectangle

along with two 11/32" holes in it. These same two holes have also been

added to the new adapter plate which will hold the brake master in

place. Now I'll need to drill two more holes through my bracket on the

car.

|

|

|

|

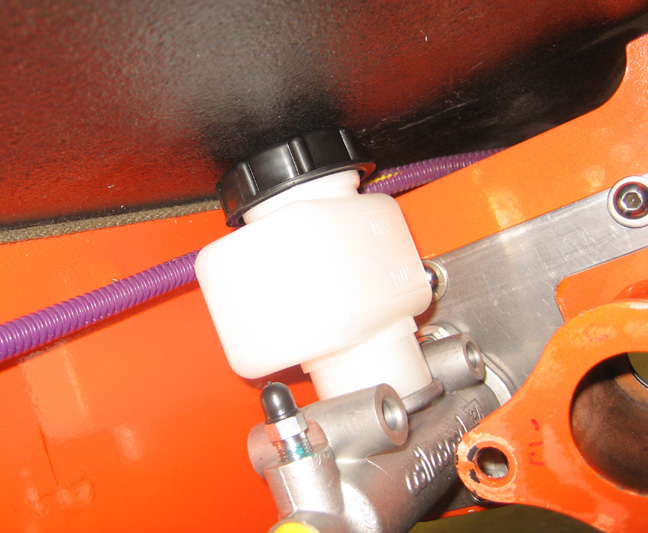

Here you can see how things will be going together which

I hope will work when I'm done. You can see how the two masters will be

staggered once they are bolted together and I rounded all the corners so

they weren't so sharp either. Looking back I really don't need those top

two bolts anymore because I have plenty more holding the new adapter

plate on. You know the old saying, if some are good then more must be

better!

|

|

|

|

When I attached the clutch master cylinder I quickly noticed that I had

a problem. I knew this would be close to the floor but not a press fit.

I tried placing a piece of paper between the cap and floor and it

wouldn't slid through which means I need to find a solution. And just

when things were going so good (as I shake my head back and forth).

Besides finding a way to get this cap off, I'll need to make pushrods

for both masters (different lengths), spacers (for both of them) and

start making up some new brake lines for each one too. Come back next

week and see how things are coming along.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

|

|

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53 |

|

54

55

56

57

58

59

60

61

62

63 |