|

Here you can see the 37 degree angle on the end of the tubing, then

there is a sleeve and last is the nut. If you look close you can see the

angle in the sleeve that mates with the end of the tubing.

|

|

|

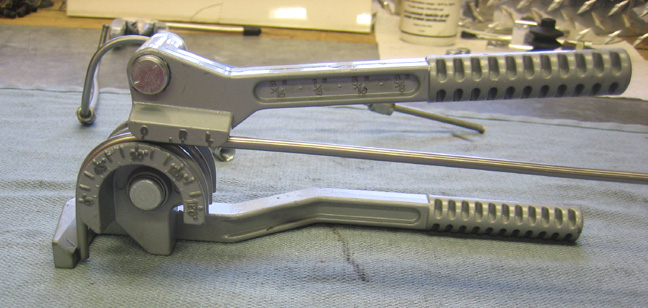

| This is my tubing bender which works pretty good and it's

cheap. It doesn't bend a really tight radius compared to some benders

but so far it's been fine for what I need.

I have a piece of tubing that is bent at a 90 degree angle here. To

do this you need to have one end against the little arm (which holds it

in place while you bend) and then you just pull on the handle to the

angle that you need. You might have to go a little farther than your

intended angle because of spring-back of the material, which is common.

To make another bend on the same material you just open the top portion,

slide the tubing where you want it and then repeat the process. The only

drawback to this bender is that it won't allow you to have short piece

on end once you're done. But I do have a workaround for that.

|

|

|

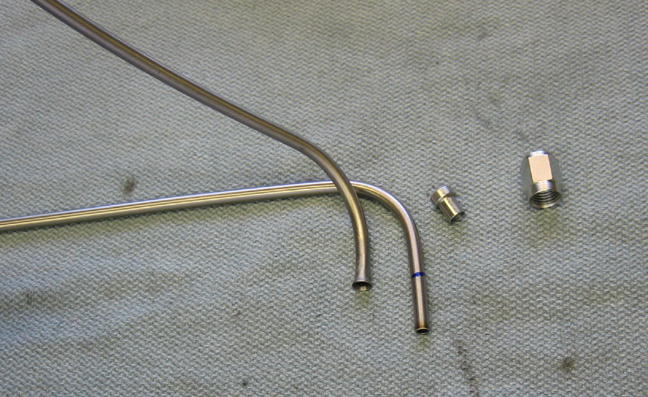

If you need a shorter piece of tubing on one end (like the one on the

left) then there's one more step you'll need to do. After bending your

first initial angle like the one above, mark the tubing at the correct

spot and then cut it to the length you need. Once you have it cut and

chamfered on the O.D. and I.D. you're ready to flare the end. This is

how I have to make a piece with a shorter end because this type of

tubing bender won't do it.

|

|

|

|

Here is a close-up of the tubing which is much shorter now after being

cut. The only thing you have to be careful of is to not cut it to short

or you won't be able to flare it properly.

|

|

|

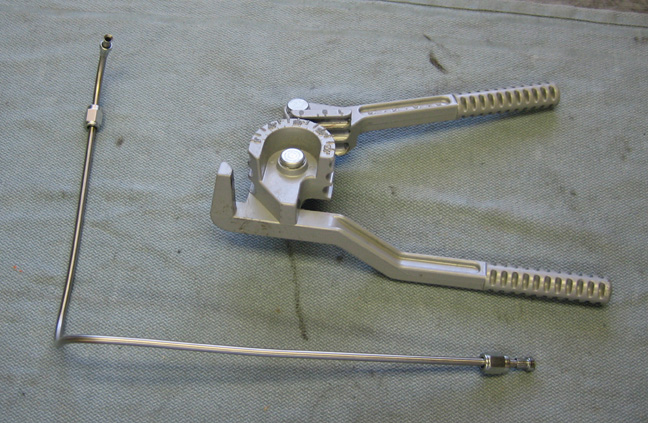

Here is the finished tubing and it came out pretty good. It only has

three bends which makes it easier to make. What I like to do if there

are more bends is to use a piece of welding rod and bend it to the shape

that you need and then bend the tubing to match.

|

|

|

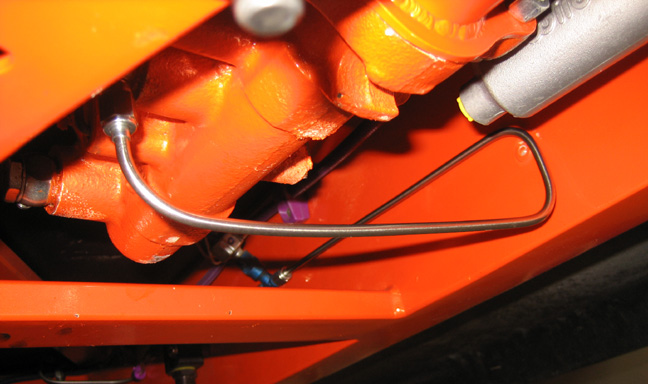

Here you can see it in place and I'll be able to use the same clamp

location for it too. Now it's time to make one for the front brakes and

another one for the clutch. The one for the clutch will require two new

clamps which I'll show you next time so because it's pretty cool. Check

back soon because I'm getting closer to my first test drive every week.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

|

|

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53 |

|

54

55

56

57

58

59

60

61

62

63 |