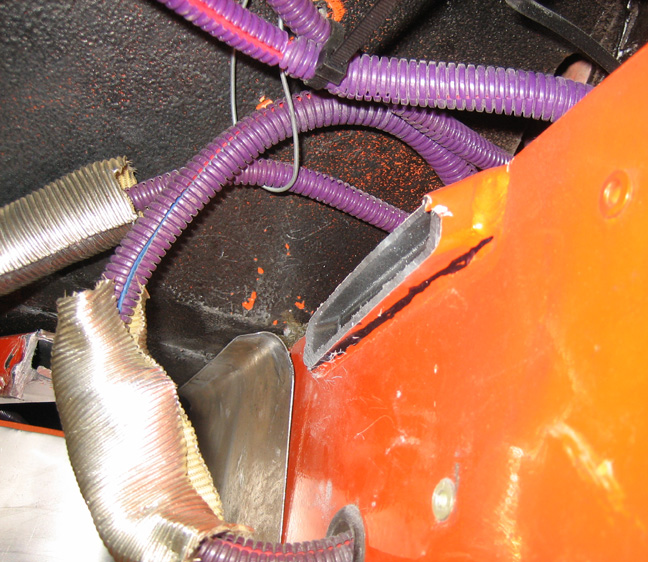

It took about five hours but I'm through cutting. To the

left is the first piece that was removed and the last cut was very long

as you can see. While I was under the car cutting this out, I took many

breaks because holding the saw up isn't the easiest thing to do. The

material is .125" thick but as you can see on the ends it's much thicker

which took longer in those areas.

|

|

|

It sure does look different with that piece cut out of there. That

silver stuff is some insulation that was used near my exhaust system

that had wires running through them. I thought this would protect my

wires while I was using my grinder so I folded it around them which

worked very well.

|

|

|

Here you can see what the floor looks like and as you can tell it

doesn't look that bad. On the other hand the saw cut doesn't look good

at all. The nasty saw cut was made by cutting from both ends and they

didn't meet in the middle like I planed. I got inpatient while cutting

from one side and decided to try from the other side. I should've stayed

on one side or the other. If you look close you can see what I mean on

the top portion which will needed a lot of grinding to clean it up. The

sheet metal is clamped in place to help protect the paint and contain

all the hot metal from going everywhere.

|

|

|

|

This is the longer cut area which is sticking out close to 1/2" on the

one side. Once I was finished grinding the smaller areas, I decided to

switch tools for this one.

|

|

|

I think this rotary tool with a carbide burr should work much faster

than my grinder would. The only drawback to using this is the type of

chips that you have to deal with. If you've ever used one of these on

steel before you know what I'm talking about. But if you've never had

the pleasure of doing so, be my guest but be prepared for the sharpest

metal chips you've ever had to deal with....and ever felt too!!

|

|

|

|

What I did here for protection is pretty silly but it

worked. The first thing I did was put in ear plugs, then a face shield,

long sleeves are a must here, gloves that you don't care about because

they are going to get filled with chips and last but not least, a big

piece of cardboard. I took a piece of cardboard and bent both sides so

it wrapped around my sides somewhat which covered me from my chin to my

knees to keep all those chips from getting into my shirt and pants. When

I was waiting for my compressor to fill back up, I'd get out from under

the car and all the chips would just slide off the cardboard when I

stood up. Although I can't say the same thing for my hands and arms

though as those sharp chips found their way to my skin pretty quick. And

sure enough I ended up with a metal splinter in the bottom of my foot,

but I didn't notice it till I was back in the house sometime later. I

guess it fell in my shoe while I was brushing myself off or something.

This method worked out really well and made quick work

of that bad saw cut. As you can see I have some paint damage which was

from the saw resting on that surface while I was cutting. A small price

to pay for getting that piece out of there without lifting the body.

Also notice all those small razor blades that have fallen onto the

bottom X member. Those things are wicked sharp so dress accordingly when

doing this kind of work. Oh...one more tip, if you were to use some tape

between your gloves and shirt sleeves that would be even better.

|

|

|

|

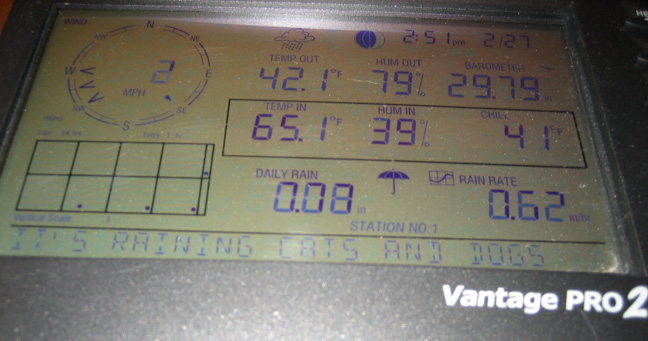

It was cold and raining that day so I took a shot of my little weather

station to show you that it has a sense of humor. Notice what it says at

the bottom when it rains hard. Next up I'll be making a piece to fill

that gap that I just made, doing some welding and I'll show you how to

do a little wiring 101....oops!

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

|

|

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53 |

|

54

55

56

57

58

59

60

61

62

63 |