|

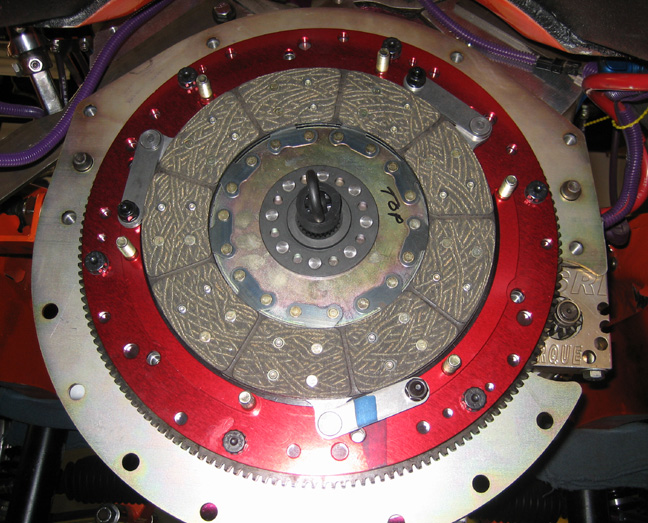

Here you can see the floater place and the top disc installed. What

you can't see is the bottom disc but the alignment tool is going through

both of them. McLeod supplied some bolts for this but I used my ARP

fasteners instead.

|

|

|

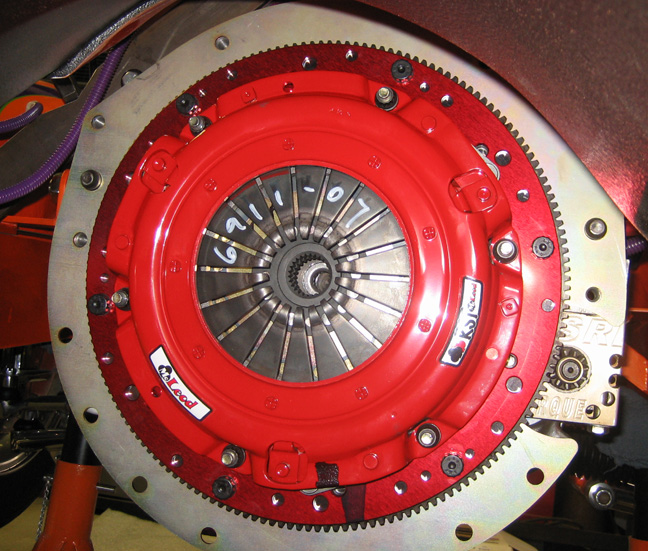

Here is the complete clutch assembly all bolted in place.

And notice the dark marks are in line with each other meaning it's

assembled correctly. If you look close you can see two sets of splines

in the center which means two discs.

|

|

|

|

Here is the scatter shield all bolted in place, at least the top half

anyways. I'll do the bottom portion soon. The scatter shield is made out

of 1/4" steel and is SFI certified which means it will pass tech

inspection if you wanted to race your car. Notice the one inch diameter

hole to the left of the large center hole. This is for a clutch pivot

ball if you were using manual linkage. I'll be using a hydraulic release

bearing in place of manual linkage so I removed the ball. Next up

will be installing the transmission which means cutting some of the

floor tunnel away so it will fit.

|

|

|

Feb. 14th.

After making sure the scatter shield cleared the clutch assembly just

fine, I wanted to make sure I didn't have any issues with anything

before assembly. Now this picture should have been before the one above

because you can still see the pivot ball installed. Anyways, what I

found was that the threaded holes for the trans needed to be cleaned out

because of powder coating.

Here I'm using a 1/2-13 tap to clean out the threads and I found out

that three of the four holes that I'll be using have a very small amount

of clearance once they go through that mounting plate. What I mean is

the holes are tapped through the plate but quickly run into the angled

surface below it.

|

|

|

The hardware that came with the kit included one sock head cap screw

(Allen bolt) because a normal hex head bolt would have clearance issues

in one location. If you look close you can see that I have some bolts

screwed in and they are both bottomed out against the scatter shield.

This is what I was referring to above and will have to be addressed.

|

|

|

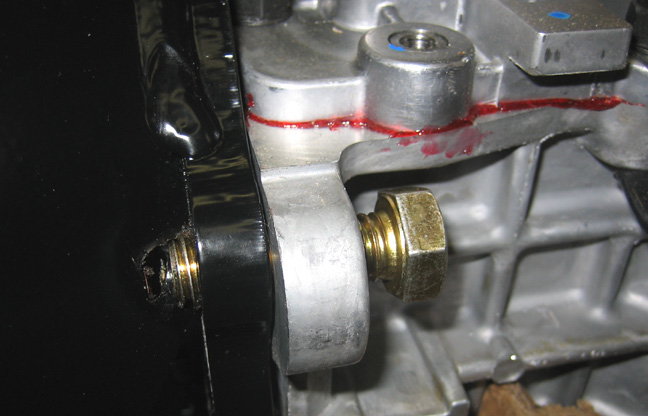

Here is a close up of the clearance problem. What I did was cut the

bolts down by 1/4" or more to make them all fit without bottoming out.

Now you would think someone would have known about this at Hurst and

swapped out these longer bolts for some shorter ones. On the other hand

It was a quick fix but kinda makes you wonder.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

|

|

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53 |

|

54

55

56

57

58

59

60

61

62

63 |