|

I used two different sizes of hole

saws to remove the bulk of the floor. Now all I have to do is

connect the dots.

|

|

|

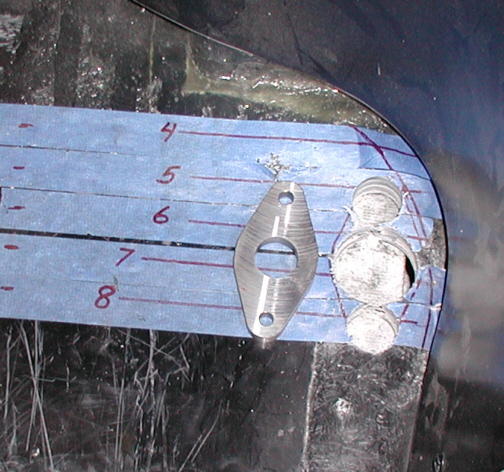

By using my die grinder and a carbide

burr that is flat on the bottom, I followed the red lines to make enough room for my piece to fit in. I'll tack weld the pieces in

place through

the center hole and then when the body comes off for paint, I can finish weld them

in place.

|

|

|

What you see here is a piece of

plastic tubing that I'm using as a mock-up to get an idea of where I

want the real tubing to go. This shot here is right next to the

passenger door in the front and wouldn't you know it, the tube is going

to end up right on one of the body hold-down bolts. I guess I have no choice here

but to remove the bolt, cut the opening for the tubing, and then move

the body bolt an inch or two forward of it.

|

|

|

Here is a close-up to give you a

better idea of what's going on. In order to remount the front body bolt,

I'll have to leave it out till the body comes off and then make an

insert to be welded in the chassis. I'll be drilling a location hole

through the body and chassis once the cage is finished so this way I

know where the hole will be when the body is off. If it weren't for

problems like this, I might be finished by now but it does look like I

have room to move the bolt and have it work. I'll be taking the car to a

guy that bends tubing on a mandrel bender in a week or so. By taking it

to his shop, I can tell him exactly what I want an he can make it

happen. I looked into buying a rollcage kit and hoping it would fit but

by having someone bend it, I can have it like I want. Let's look at

some other part of the interior for now.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14 15

16 17

18 19

20 21 22 23

24 25

26 27

28 |

|

29

30

31 32

33 34

35 36

37 38 39 40

41 42

43 44

45 46

47 48

49 50

51 52 53 |

|

54

55

56 57

58 59

60 61

62 63

64 65

66 67

68 |