I had the down-bars that go through

into the trunk area bent because of how the body is shaped. I was

thinking that if they were bent, it would make the installation easier

so they wouldn't interfere with the body. The one drawback is that you

loose a lot of strength by bending them. I was told by an NHRA tech guy

that I was okay to bend them up to 30 degrees so this is what I had them

bent to. I started by using a piece of welding rod and bending it at

the same angle the tube was so I could get a good idea of how big of a

hole I needed to make through the bulkhead. I ended up bending four different

pieces of welding rod with the same bend but different lengths to

simulate the tube being cut to different lengths. I drilled a 1/4"

hole in the bulkhead to poke the welding rod through in the place I

thought that would work. After placing the welding rod through the hole,

I needed to drill in a different place and tried the fit again. I now

thought I had the starting place and used a 1 3/4" hole-saw and did

some cutting. The reason for the 1/4" hole to begin with is because

this is the size of the pilot drill in the hole-saw. If you've ever tried to

use a hole-saw without the 1/4" pilot drill, you'll know why I did this

because it will jump around all over the place and not let you cut.

|

|

|

After some trial fitting with the

welding rod, I didn't like the way it was going to fit so I tried a

straight piece to see how it looked. The NHRA rule book says that you

can have the down-bars a maximum of 5" below the main hoop to start

the trip back into the trunk area. The straight piece looked like it was

going to work and I didn't think they would which is why I had them bent in

the first place. I cut a piece at 39" and started grinding it to

fit the main hoop.

|

|

|

After making a hole in the bulkhead

large enough for the bent piece, then switching over the the straight

one, I had an opening way larger than I needed or wanted. The good news

is that the straight piece is going to work which means it will have

much more strength. The one thing I had to make sure of is to have the

down-bar clear my upholstery that was already finished in the trunk area. The

bar is going to be very close to one panel but I think it will work. I

have a clamp holding the tube from falling through the hole I made in

the floor of the trunk so I can see how long I need to cut it off

at.

|

|

|

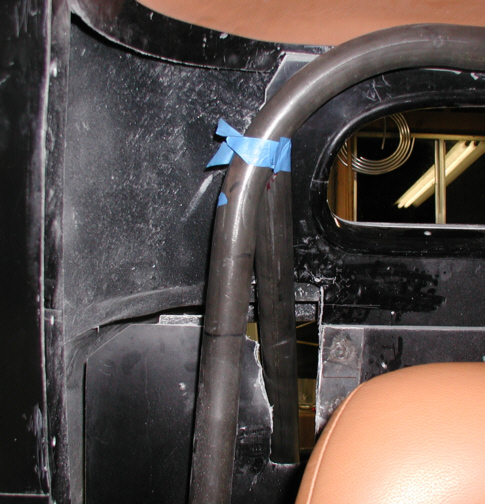

To help me hold the tube in place, I

used my old friend blue masking tape. This stuff works great for a third

hand if you ever need to hold something for short periods of time. In

this shot, you can see how it's not at the top of the main hoop. I

marked a spot five inches down from the top and started fitting the

down-bar in that location. You can also see how large the opening for

the tube is.....yikes!! The other side will be much smaller now that I

know what I'm using.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14 15

16 17

18 19

20 21 22 23

24 25

26 27

28 |

|

29

30

31 32

33 34

35 36

37 38

39 40

41 42

43 44

45 46

47 48

49 50

51 52 53 |

|

54

55

56 57

58 59

60 61

62 63

64 65

66 67

68 |