I used my 1 3/4" hole saw and

then used my die grinder to get the shape I needed for the 1/8" tube plate to

clear the floor of the trunk. Here you can see the tube that needs to be

cut and angled and then I need to build a support for it. This is

the other side in case you're wondering because I got ahead of myself

and forgot to take a picture but looks the same.

|

|

|

I unhooked the rear-end and dropped it

down so I could get to the bottom of the tube and bracket easier. I needed to weld a

shelf to the chassis so the tube could be attached to it. Why did I need to do

this instead of fastening it to the chassis? There was a couple of

reasons. One, I already had my upholstery done in the trunk which meant

that I had to work around it (not very good planning on my part) and

two, the angle of the down-bar wasn't enough to end up where I wanted it

because I wasn't able to run the tube from the top of the main hoop.

What I plan to do is make a triangular shelf for the tube to bolt too.

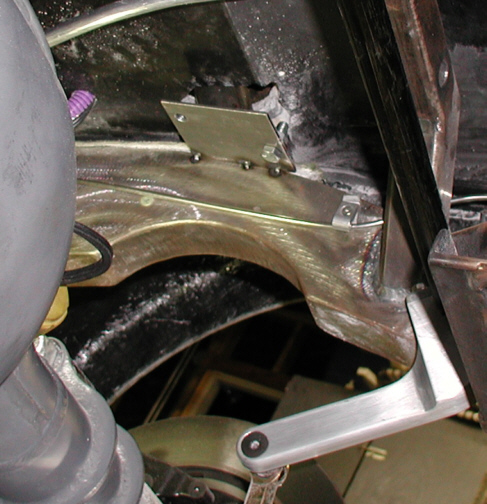

Here you can see that I've tack-welded the top piece in place. I first

tack-welded the 1/8" plate to the tube, then I held the shelf plate

up to the tube plate and marked around the tube plate with a marker as

far as I could. Then I removed the shelf plate and marked where the two

3/8" holes needed to be and drilled them. After checking to see if

the holes lined up, I put two bolts through the holes to keep them lined

up and tack-welded the plate in place that you see below. Now I'm ready to make the support

for the shelf. I'll fully weld the plate in place once I remove the body

from the chassis when I'm ready for paint.

|

|

|

This is the bottom of the down-bar

which has the 1/8" plate welded to it. I welded the plate on at an

angle (you can't tell in this shot) so I could get a nut on top without

it interfering with the tube. If I had welded it on inline with the

tube, I found out that I wouldn't have enough clearance to work

right.

|

|

|

This is the other end of the down-bar

that gets welded to the main hoop. It took awhile to make this cutout

because I used an 4" angle grinder and file to end up with this

shape. To start with I cut the tube at a 45 degree angle and then worked

it from there. Now that the down-bars are cut and fitted to the right

length, I need to cut them in half before I can weld them in place. Why

am I cutting them in half? So I can take it apart when the time comes to

remove the body, along with installing the upholstery.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14 15

16 17

18 19

20 21 22 23

24 25

26 27

28 |

|

29

30

31 32

33 34

35 36

37 38 39

40

41 42

43 44

45 46

47 48

49 50

51 52 53 |

|

54

55

56 57

58 59

60 61

62 63

64 65

66 67

68 |