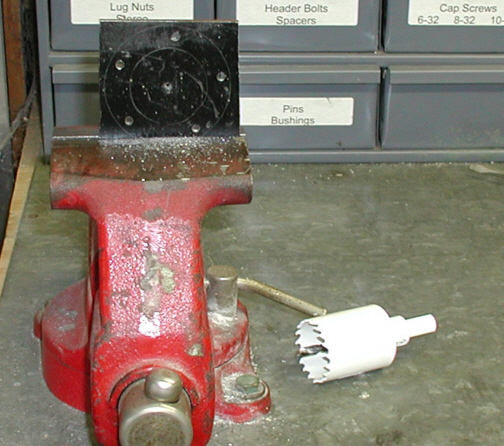

The way I plan to fasten the sending

unit to the tank is by making a five position nut-plate out of 1/8"

thick steel. I scribed

around the gasket that came with the sending unit which acted like a

template and then I'll cut away the center with a hole saw. This

plate will be welded to the inside of the tank when finished. At this

point, the five 8-32 threaded holes have been drilled and tapped.

|

|

|

I used a belt sander to finish the O.D.

(outside diameter) and then a die grinder to dress-up the I.D. after

using the hole saw. I'll be using button head stainless cap screws

to fasten the sending unit to the tank. Now all I have to do is weld it

in place and to do that, I'll need to get started on cutting out some

sheet metal.

|

|

|

|

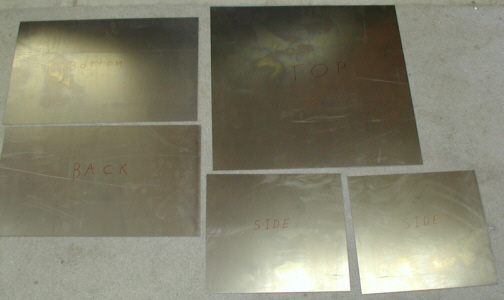

This is the material that I'm going to

be using for my fuel tank which is .035" thick steel. I sheared the

pieces to the sizes needed and I'm now ready to cut some holes.

|

|

|

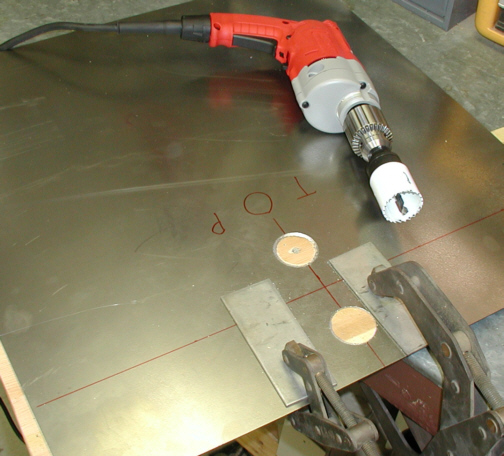

What I'm doing is cutting out one hole

for the fuel sending (bottom) unit and the other is where the filler

neck and gas cap

will be. These holes are 1 5/8" diameter. The line that you see

running from left to right is going to be the transition from the top of

the tank to the radius that will go towards the bottom. I'll also be

adding one more hole for a rollover valve but we'll get to that later.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14 15

16 17

18 19

20 21 22 23

24 25

26 27

28 |

|

29

30

31 32

33 34

35 36

37 38 39 40

41 42

43 44

45 46

47 48

49 50

51 52 53 |

|

54

55

56 57

58 59

60 61

62 63

64 65

66 67

68 |