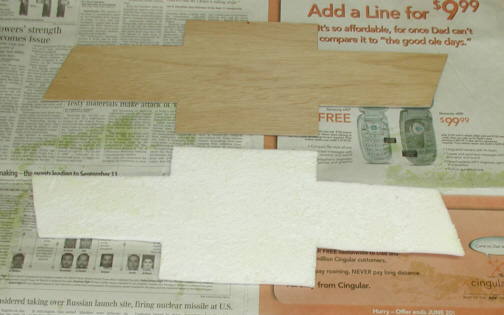

With the piece of wood cutout, I'm now

ready to glue it to the foam. Using newspaper behind whatever I'm

gluing helps to keep the cleanup to a minimum. At this point, the foam

and wood piece were oversize which meant all the outside surfaces (12) had to be just a

little smaller. The reason is because there will be four layers of material

occupying

the space of a razor blade cut, so I had to make some much needed clearance

or things wouldn't fit.

|

|

|

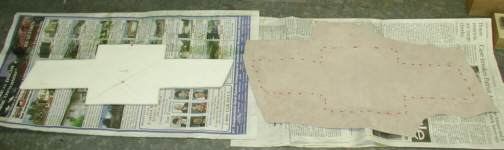

I glued the primary color to the

headliner first so I could find out how much clearance I needed. Now that the emblem has the proper

clearance, it was time to glue some material too it. I made sure I had

plenty of extra overhang in case I didn't get the two lined up and so

far, it's worked out good. Before I put the material on, I placed the

wood and foam piece in the headliner and drilled nine 1/8" holes

through it so I could fasten it down. I'll show you how I'm going to do that

soon.

|

|

|

Here is how the opening looks where

the bowtie will be going. I cut the material away from the middle and

then trimmed it right up to the sides. I didn't want any material to be

on the bottom because this would add to the overall thickness. I already had

1/8" to much because of the use of the wood behind the foam so by

not adding anything else would cut down on the

overall height. It's hard to see here but if you look close, you can see

the nine holes that go through the fiberglass.

|

|

|

The bowtie is finished and came out good for my first

time doing something like this. It took about an hour to trim all those

edges and at this point, it's ready to be installed into the headliner.

But let me show how the back looks first.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14 15

16 17

18 19

20 21 22 23

24 25

26 27

28 |

|

29

30

31 32

33 34

35 36

37 38 39 40

41 42

43 44

45 46

47 48

49 50

51 52 53 |

|

54

55

56 57

58 59

60 61

62 63

64 65

66 67

68 |