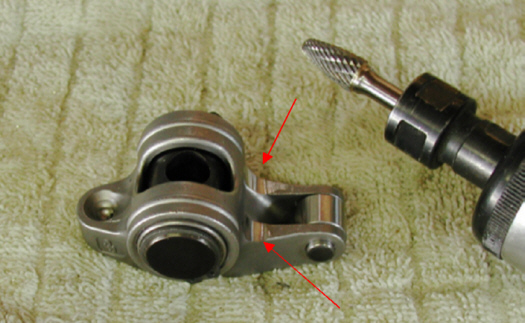

As you can see I didn't buy new

rockers so I made my own clearance with my die grinder. I sure have used

this tool a bunch and will probably use it more before I'm finished. Now

the chips that come off these rockers are heat treated and get into you

skin easy because there're so sharp (now how do you think I know that).

I'll be cleaning all the bearings in solvent before I assemble

anything.

|

|

|

The engine builder said "Let

there be light....and there was light". Notice the clearance

between the spring retainer and the rocker arm now. It only took a few

minutes per rocker to produce enough clearance to make the difference.

How much is enough here? Any is enough but I gave it a little extra just

to make sure. Now it's time to set the proper valve lash, which is

.028" and then I can start checking the travel of the rocker arm over

the valve stem. What I mean is, while the valves are going up and down,

the rocker arms are moving too. The rockers push down on the valves but

when they're pushing, there moving along the top surface of the valve

stem. This movement should be centered on the top of the valve stem as

it moves. If not, the valve guides will get worn prematurely

on one side or the other depending if it were to far forward or

backward. By adjusting the screw in the pushrod, I can make sure the rocker arm stays

centered through out it's motion which in turn will determine the

correct length. I put a small amount of grease on

top of the valve stem, then cranked the engine around a few times and

then checked the pattern that it left. After adjusting the screw in the

push rod, I was able to achieve the correct pattern (even amounts of

grease left on both sides of the valve stem) which meant the length was

right. I came up

with a length of 6.500". Now this is short because a

stock one is 7.800 long so I'm talk'n over 1 1/4" difference here.

That's fine because that means the shorter ones will weigh less. Anytime

that you have lighter moving parts, that translates into higher RPM and

more horsepower. I also checked valve-to-piston clearance to make

sure I wasn't going to hit anything. The minimum you want is about

.100" and I had over .375" which is a bunch so I won't have to

worry about a valve hitting my pistons. Should of bought a bigger cam is

guess...

|

|

|

After a call to Iskenderian, my

pushrods arrived. There're made out of heat treated 4130 steel with an

.080" wall thickness which will be more than enough for my needs.

Most companies, like Isky, sell these in increments of .050" long

so that makes it easy to find the right length. Iskenderian claims that

there product has the highest stiffness/mass ratio. These also have an oil hole that goes through to oil the top of the

engine. I'm just about ready to install the valve train and then put in

the motor. One more thing has to be done though and that's paint the

engine block. I'll be ordering some paint next week and then breaking

out the paint gun.

|

|

|

Here I'm getting ready to install the guide plates

and rocker studs. The studs will get some assembly lube along with some

black RTV compound. Only one stud will be needing the RTV because the

intake studs break into the intake ports so this will keep them from

leaking.

|

|

|

|

1

2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25

26 27

28 29 |

|

30

31 32

33 34

35 36

37 38 39

40 41

42 43

44 45

46 47

48 49

50 51

52 53

54

55 |

|

56 57

58 59

60 61

62 63 |