The last thing that came was my gages.

This should have gone in the body section but I was on a roll so here we

go. These are all made by

Autometer

and are the Ultra-Lite series. We have some that are mechanical and

electrical. The mechanical ones are "water temp", "oil

pressure", transmission temp". The electrical ones are

"gas gage", "speedometer" and "

tachometer". The speedometer is nice because it's programmable. All

you do is tell it what size tire you have, what gear ratio and it

figures out the rest. You can change tire size and all you have to do is

reprogram it...sweeeet! It also has an odometer and trip meter. The

odometer doesn't loose information even if the battery is disconnected.

The small gages are 2 1/16" in diameter and the larger ones are 3

3/8" in diameter.

|

|

|

Now for the hell of it, I emailed a

couple of companies that I've spent LOTS of money with and asked them if

they would send me a t-shirt (for free). One of them told me to send them

my name, addy and size so they could ship one out. This company was Dart

(which I've spent thousands with) which I give props to. I guess it

doesn't hurt to ask now does it. Thanks guys....it fits great. I'll have

to try my luck with a few more companies because you never know....

|

|

|

| I'm Head'n Down The Road...

Now that the heads are back together and

the one seat fixed, I

needed to find out how long the pushrods were going to be. I had to many

factors involved in trying to calculate the length. First my valves were

.100" longer than stock ones. Now if that was the only thing different,

no problem but I also had a smaller base circle cam (.900" in

diameter) along

with longer roller lifters. Now lots of companies sell adjustable

pushrods but I thought I could make one. The first thing I needed was

some tubing and after working with my brake lines just the other day, I

thought this would work fine. After measuring with a tape measure and

learning that about 7" would be more than enough, out came the

Dremel to cut a piece of tubing. Now how was I going to make this into a

pushrod that would work with those heavy springs? I wasn't....I was

wanting it to work with some softer springs for testing only.

|

|

|

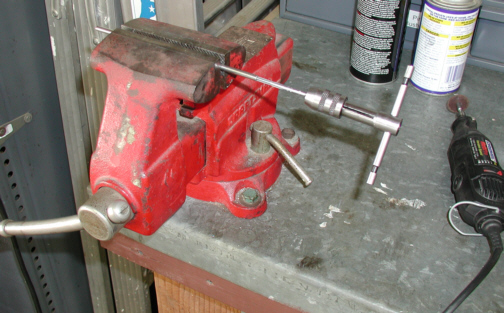

By tapping the tubing (cutting threads

inside the tube), I could use a

screw at each end. This is a 6-32 tap and I had a hard time with this

stainless tubing because it has a seem inside that travels the whole

length. After a few clicks-and-pops (now this is a bad thing to hear

from any tap and it's even worse when it's this small) I had enough

threads inside to hold my screws.

|

|

|

|

1

2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25

26 27

28 29 |

|

30

31 32

33 34

35 36

37 38 39

40 41

42 43

44 45

46 47

48 49

50 51

52 53

54

55 |

|

56 57

58 59

60 61

62 63 |