|

33 Coupe Engine 5

5/18/03

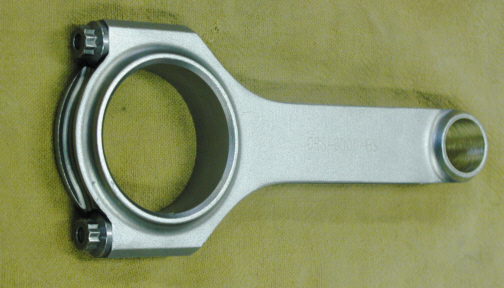

This is the connecting rod on its

side. Now if you can picture cutting it in half, you can see why the

call it an H-beam rod. Notice the oil hole at the top (right side).

There is one on the other side as well and it's there to add oil to the

piston pin. These rods don't have nuts as the threads are tapped into

the body of the rod itself. The bolts are made by a company called ARP

which makes high grade fasteners. Most of the fasteners will be from ARP

that go into my car.

|

|

|

Notice the large chamfer in the big

end. This is to clear the .125" radius on the crankshaft. If this

were not here, there would be some serious binding going on. You can

also see the 12 point rod bolts. They're made this way to be small and

strong. By having 12 points, it's harder to strip them when torquing.

|

|

|

Here you can see the two oil holes a

little better. The larger hole has a bronze bushing in it. The bronze

has some oil added to it when it's made so this is why they use this

material.

|

|

|

Eagle even give you some lubricant to

put it together with because if you don't put anything on the bolts

(threads) when you torque them, your asking for trouble. A dry thread

has to work much harder than a slippery one and it also doesn't give you

a true torque reading. This ensures that you do and I will be using it

later when It gets assembled.

|

|

|

|

1

2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25

26 27

28 29 |

|

30

31 32

33 34

35 36

37 38 39

40 41

42 43

44 45

46 47

48 49

50 51

52 53

54

55 |

|

56 57

58 59

60 61

62 63 |

|