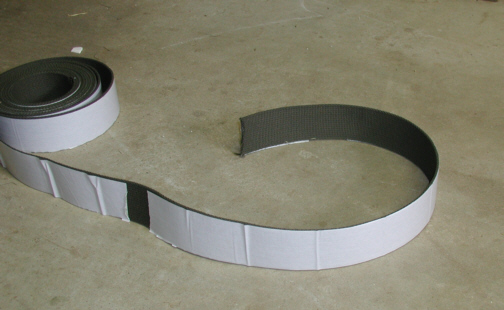

You can see the adhesive backing on

the webbing here. This stuff is very tough, like extra thick cloth that

has a cross pattern in it which

means I won't be able to drill holes in it so I came up with another way

to make clearance for the bolts.

|

|

|

After cutting two lengths and laying

it out on the frame rails, I then made marks with a red felt marker to

line-up with the inserts in the chassis. Now it was time to cut some

holes and to do that I made a tool out of a drill bushing and ground a knife edge on

it. A drill bushing is made out of hardened steel which means it will

hold an edge like a knife does. Drill bushings come in lots of sizes and

this one was 1.00" on the outside diameter, 3/4" on the inside

diameter and 3/4" long. Aligning the tool over the layout marks was

easy as you can see.

|

|

|

By using a soft-face hammer and a

piece of wood under it, the holes came out nice. The diameter of the

hole that got punched out is 3/4" and should provide plenty of

clearance for my bolts to go through. If your wondering why the hole is

off center, the chassis had a lot holes that were on center and some

that were not. I guess there is a reason for this but I don't know why.

The hole below is in the right place...trust me.

|

|

|

|

The piece of webbing on the frame rail

has four holes in it and is ready to stick down. After making sure

all the holes were in the right spot, I made one for the other side.

Lets get that body on there and see how it looks!!

|

|

|

|

1

2

3 4

5 6

7 8 9

10 11

12 13

14 15

16 17

18 19

20 21

22 23

24

25

26 27

28 |

|

29 30

31 32

33 34

35 36

37

38 39

40 41

|