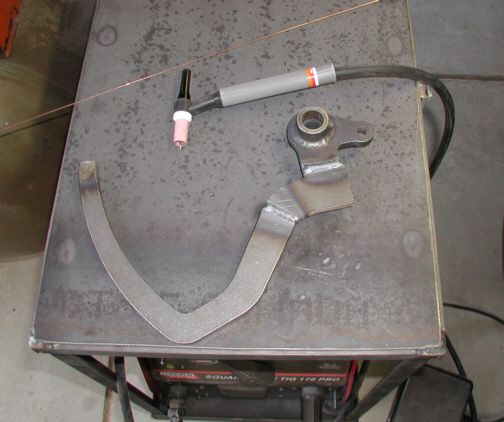

This is how it looks after welding. I

welded one side and then let it cool a little bit. Then I welded the opposite

side and repeated the process till it was fully welded. The reason for

this is because there is some kind of bushing inside the pivot hole and

I didn't want it to come out or distort. I double checked the

straightness of the arm as I went along to make sure it stayed

straight.

|

|

|

After the welding was completed, I

wanted to make sure things were still in a straight line so I held it up

to look at it. I wanted to see it at a different angle and wouldn't you

know it, the "branding iron" got away from me for a moment. It

didn't feel to bad at first but then after an hour went by, the

"stars-and-moons" started floating around my forearm (big time

pain started to set in). I hate when I burn myself!!

|

|

|

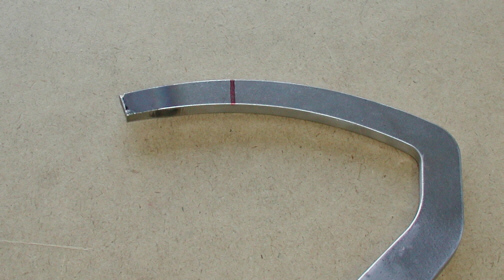

Here is the arm after knocking down

the welds with a grinder and then sanding them with my air grinder with

a sanding drum. It came out nice and now it's time to see how much I

have to cut off the end.

|

|

|

I bolted the arm back up, pressed the

arm all the way down (till it wouldn't move anymore) and then marked the

spot that needs to be cut. This line was parallel to the floor at this

point. From the red line to the end is about 3" and was whacked

with a hack-saw. After a quick deburr on the end of the arm, I'll be

ready to weld on the piece that will hold the pedal in place.

|

|

|

|

1

2

3 4

5 6

7 8

9 10

11 12 13

14 15

16 17

18 19

20 21

22 23 24

25 26

27 28 |

|

29 30

31 32

33 34

35 36

37

38 39

40 41 |