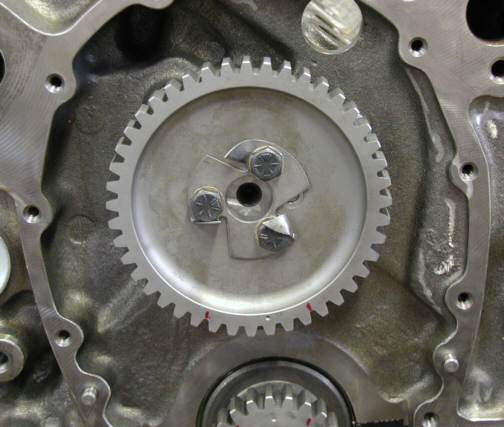

Now that I'm done with degreeing the

cam, it's time to put the lock washer in place. This washer is designed

is to make sure the bolts DON'T come loose. If you notice at the top

bolt, the tab is slightly bent outwards. On the left bolt, the tab is

bent at a right angle to the gear face and the last bolt has the tab

bent all the way around the bolt. This is a great way of making sure

that bolts stay put.

|

|

|

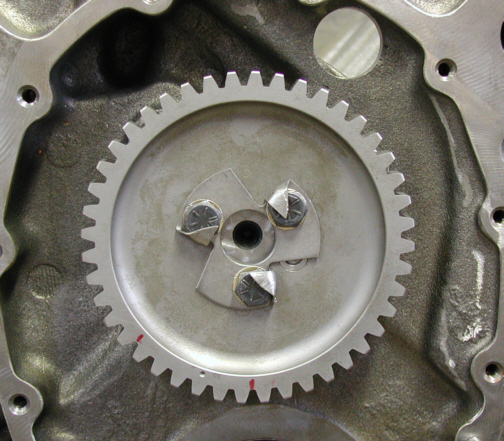

This is a shot of all the tabs bent

and finished. To bend the tabs, I used a hammer and 3/8" diameter

drive punch. This way you can get the tab right up next to the flats on

the bolt head insuring a good tight fit.

|

|

|

Now it's time to check the fit of

timing cover and how much clearance we had between the two idler gears

and cover. Well I had a large gap between the cover and block (no surprise

there because if something were to fit right, I wouldn't know what to

do) so that meant that the idler gears were sticking out to far. The gap

was about 1/8" so I did some measuring and ground some off the back

of the axles of the two gears. You have to have at least 90% engagement

of these gears with the other gears so after some careful metal removal,

I had reached my limit. The gap was better but not gone so I had only

one choice as to where to make more clearance.

|

|

|

Here you can see the grease that I put

on the ends of the two axels that transferred to the timing cover. This

is the place I had to remove more material to make enough clearance for

things to fit. I used a felt marker to put a red line around the grease area for reference and

got to work.

|

|

|

|

1

2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25

26 27

28 29 |

|

30

31 32

33 34

35 36

37 38 39

40 41

42 43

44 45

46 47

48 49

50 51

52 53

54

55 |

|

56 57

58 59

60 61

62 63 |