I've been really having trouble

deciding what engine to put in the car. What I mean is, I know I want a

small block Chevy but I wanted something to set me apart from so many

others out there. What I came up with was a stroked small block. What's

does "stroked" mean?? It's when you put in a crank shaft that

has a longer stroke than the original one has. In this case, the one I

wanted would have a 4.00" stroke rather than a 3.5" like a 350

cubic inch has. Now I know

this doesn't sound like much but add to this a larger diameter bore of

4.155" and we have a larger cubic inch motor. How big you ask, well

after doing the math this will be a 434 cubic inch small block. With this

size motor, it should set me apart from most and I should have plenty

of torque as well. Let's go through some of the components that I will

be using.

|

The block is the foundation for any

engine and the one I will be using is not made by General Motors (GM),

it's made by a company called

Dart. Why didn't I use a GM block?? There

are lots of reasons so let's go through the list. First a

"good" GM block is hard to find and I wanted one that had

four-bolt mains (four bolts on the three center main bearing caps). The

Dart block takes it one step farther by adding the four-bolts to ALL

five main caps. By having all these bolts it adds strength to the whole

assembly which is a good thing. Also, this block has priority main

oiling which means it oils the main bearings first compared to the GM

block that oils the cam bearings first and then the mains. The Dart

block also has thicker material in the critical places, like in the

cylinder bores. Even though I am boring this out to 4.155", there

is still over .250" of wall left. A GM block doesn't even come

close to that.

|

|

|

Here you can see the bottom of the

block and all five of the main bearing caps with four bolts each.

Another thing this block has it thicker oil pan rails so you can grind

for rod clearance and won't have to worry about hitting water. I'll show

a better picture of what I mean later. Now all this extra material is a

good thing but there's always some bad to go with the good. The bad part

is that it weighs more than a GM block but not by much. The difference

is something like 20 lbs or so. Some of the extra weight has been added

to the web under each main bearing area which is something that has been

a problem with the GM blocks because they are prone to cracking there.

|

|

|

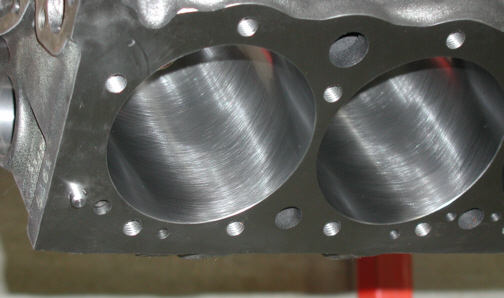

This is a shot of how the bores came

out after I got it back from the machine shop. Now these look great and

Dart has instructions on how the block should be bored and honed. When

you get within .003 of final size while honing, your suppose to change to a finer

stone and bring it to size. Then change to a finer one again and

stroke it three times again. One last change to an even finer stone and

then stroke it three more times. After all this the cylinders should be

good to go. One other thing Dart does is blind tap the threaded holes

for the heads. GM's holes go into water so this is another plus.

|

|

|

This shot is in the valley (middle

when looking down on the top of the block) of the block where the oil

drains back to the oil pan. GM blocks don't have these slots like this

but have holes on each end (one in the front and one in the rear). Well

I like this idea because the oil will have to drain back down right on

the cam. Why is this a good thing? Anytime your idling and engine for

long periods of time with a BIG cam, your asking for trouble because the

cam relies on the splashing effect from the crankshaft to oil the lobs

of the cam. If the RPM of the engine is higher then there's not to much

to worry about. I just see this as some insurance to oil the cam at all

times. Notice the casting flaws in the corners and all through the

slots.

|

|

|

To get as much oil as I can I had to remove all the

flaws so out came the

Dremel for that job. This tool makes fast work when uses with a

1/8" carbide burr.

|

|

|

Now this looks much better after the

rough edges are all gone and I added a little chamfer around the slots

too. This should drain a little better now.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25

26 27

28 29 |

|

30

31 32

33 34

35 36

37 38 39

40 41

42 43

44 45

46 47

48 49

50 51

52 53

54 55

|

|

56 57

58 59

60 61

62 63 |