|

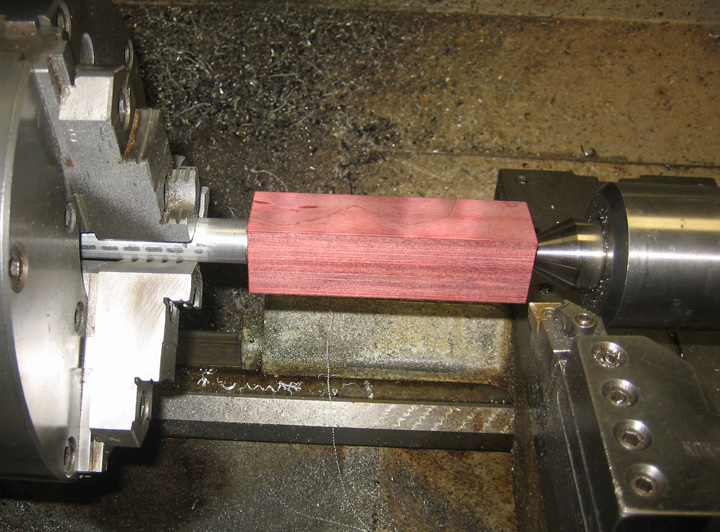

I going to drill two 3/8" holes (in the center) at both ends of the block.

These holes will be for the sharpening steel and the decorative end that

has the ring on it. They will also assist me in holding the block while

I'm machining it.

|

|

|

I turned down some aluminum bar stock to 3/8" diameter so

it would fit into the block and then used a live center at the other end

so I could turn it. This worked great but I forgot to bring my mask

while I was working. This stuff smells so bad while it's being machined

that I'll never use it again!! In fact a couple of employees came over

to see what I was doing and soon left. Yes....it's really that bad.

|

|

|

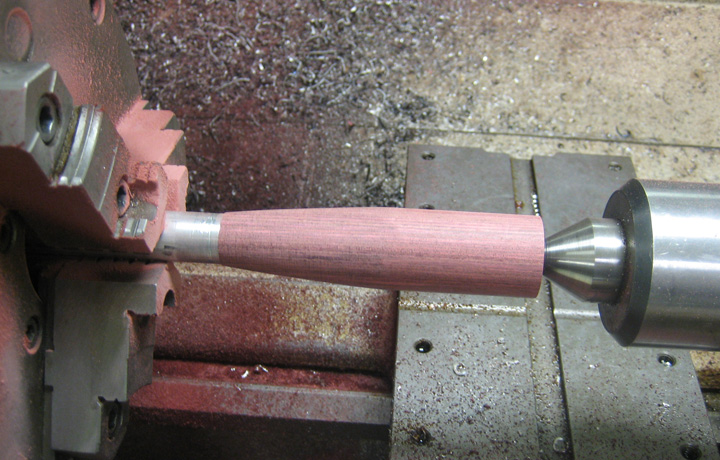

The aluminum bar stock (clamped in the chuck) is 3/4" (.750)

diameter and I wanted each end of my piece to be .800" so this gave me

just enough room to work with and I also used that diameter as a

reference. To get the shape that you see I used one hand on the cross

slide and the other on the carriage and worked from the center towards

the chuck. Now this isn't easy to do because you're using both hands at

the same time and one of them seems to have a mind of its own. If you're

a machinist, you know what I'm talking about here. And the ones that are

not, let's just say one hand is dumb and the other isn't because it's

hard to stay in sync with each other.

|

|

|

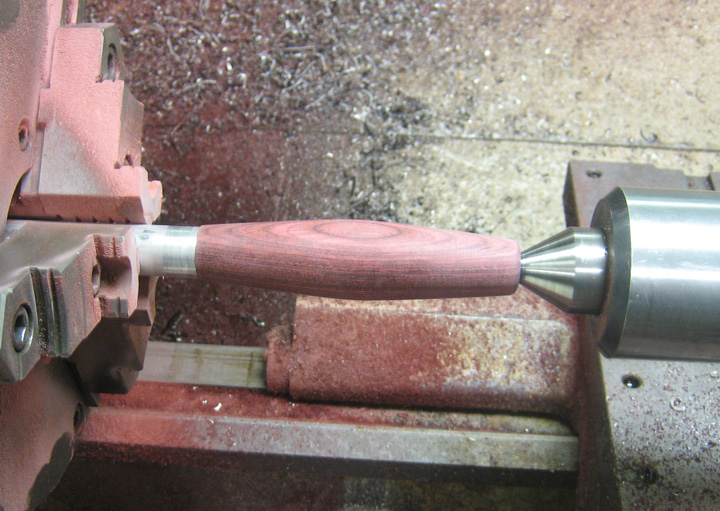

I did one half and then turned the handle around and did the other. Once

I had it roughed out I used a file to get the final shape. When I was

happy with the shape I sanded with 100, 180 and then 220 grit

sandpaper.

|

|

|

|

I put a small radius on one end only. This radius will

be against your hand because the other end is against blade-guard. I

thought of this while I was sanding because it's much easier to form while it's

turning in the lathe.

|

|

|

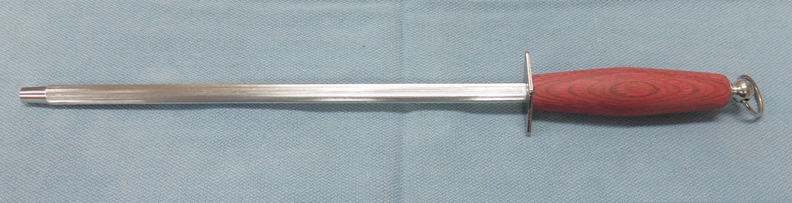

I needed to sand the end of the sharpening steel a small amount so it

would fit my 3/8" diameter hole. The sharpening steel had serrations on

the area that goes into the wood handle, which would help it from coming

loose. Those serrations are gone now (after sanding) and I'll have to

rely on the press fit that I ended up with to keep the handle from

coming off. If it ever does come loose I can always use some epoxy to

keep it from doing so again. The size of the steel is 12" but

the overall length is 17 1/2"

|

|

|

|

I finished with some 320 grit paper once I was home and it feels pretty

good when you hold it. You know the old saying, 'if it feels good in my

hand...it will feel good in yours' : ~] You can also see the guard against the handle

here and the reason I didn't put any radius on that end.

Well it's finally that time...time to put it all together and see

what it looks like with all the hardware in place. This

project took many weeks, many hours and a lot of hard work but I think it came out

like I envisioned it would.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14 |