Here are the tools needed for making

up these plug wires. If your wondering why I'm using WD-40, it's because

the plug wires are made out of silicon and that stuff doesn't slide

through those rubber boots very easily. First you cut the wire to a

rough length (I'll be trimming them to fit later), then you spray the

wire and boot and then slide the wire into the boot as far as it will

go.

|

|

|

Now you take the needle-nose pliers

and grab the end of the wire pulling it through. After about the third

try and only pulling out pieces of the wire, I found out that I had to

pull the wire back out and spray everything one more time. It was like

the rubber or silicon soaked up the WD-40 and wouldn't move.

|

|

|

Notice the end of the wire and how

chewed up it is. No problem because I cut it long so more has to be

trimmed off. See how shinny everything is because of the WD-40! It seems

like the more you use, the easier it is to assemble.

|

|

|

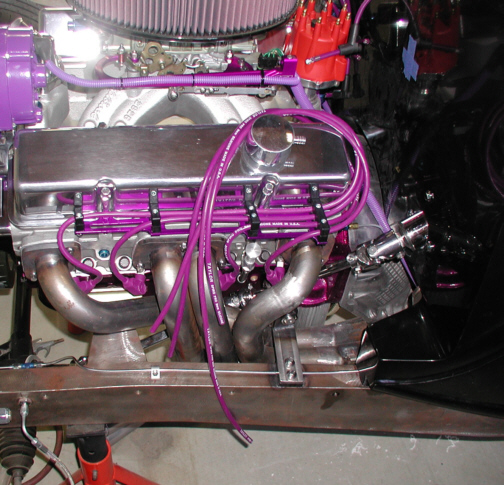

Here you can get an idea of what

things are going to look like. After installing the wire looms and

running the wires through them, it's time to cut these to length and

install all the boots. The loom has four wire separators on each side.

As you can see, they start off with four then three, two and then one.

The small black separators are made out of plastic but are glass reinforced

so that they take heat better. They are held on with socket head cap

screws and lock-nuts. I'll show you the rest when I finish which will be

this weekend so don't no body go nowhere.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26 |

|

27

28 29

30 31

32 33

34 35

36 37

38 39

40

|