|

Valve Train Problems 3

3-14-14

| An Unexpected Problem

Once I had the heads and the rev-kit out of the way, I

was able to remove and inspect the remainder of my valve train. As I

started pulling my roller lifters out things were looking pretty good...

till I got to the third or fourth ones. Once I had the first bad lifter

in my hand for an up close and personal look, all I could say was, "what

the hell"??!! The damage to this lifter was another eye opener (as I

once again shake my head from side to side). And again I had to ask

myself, "how did this happen"? Yeah I was talking to myself all alone in

the garage.

Now don't tell me that you've never talked to yourself while being

alone....yeah...that's what I thought.

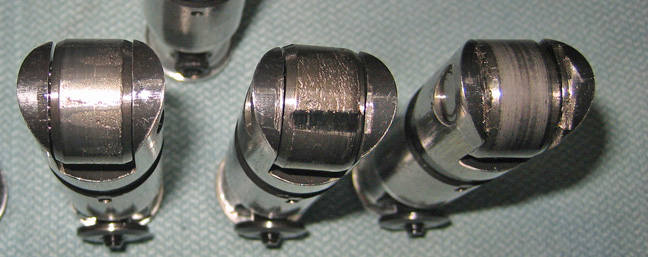

The single lifter by it's self in the back is for reference because

it's a good one. On the other hand the other four didn't fare so well.

|

|

|

|

Look at the middle one with that huge groove across the middle of the

roller. The only thing I can think of that would cause this would be for

the bearings to have failed internally which made the roller stop

moving. If that was the case then I could see the lobe of the cam might

have beaten that groove into the roller but I'm not sure.

You can also see the one on the left was rolling intermittingly to

have a ware pattern like it has. Probably another bearing failure. Now

the one on the right has had some kind of failure as well because the

roller is well below the outer surface.

|

|

|

|

Here is a better look at the right hand lifter that now has the roller

below the surface. The one on the left is what it should look like.

Truly unreal. And again, the engine didn't run that bad is what gets me.

Now if these lifters look this bad...what does my camshaft look like???

Spoiler alert here...it didn't look good. At least from what I could

see of it through the lifter bores. Once I rolled the engine around and

looked at each lobe with a flashlight, it definitely wasn't good news.

I sat down with my hand against my forehead with only my finger tips

and thumb touching the left side of my head, eyes shut, face looking at

the ground and shaking my head from side to side again in disgust. I was

trying to take it all in while sitting there and all I could do was

think about how bad the cam looked and what would need to be done to fix

it.

I opened my eyes, got off the chair, walked over to the car, got out

my flashlight again and took a second look. I rolled the engine over one

more time and right then I knew what I had to do, the cam would need to

come out. If it looked that bad through the lifter bores, then I could

only imagine how it would look up close. Son-of-a-bitch!!

|

|

|

|

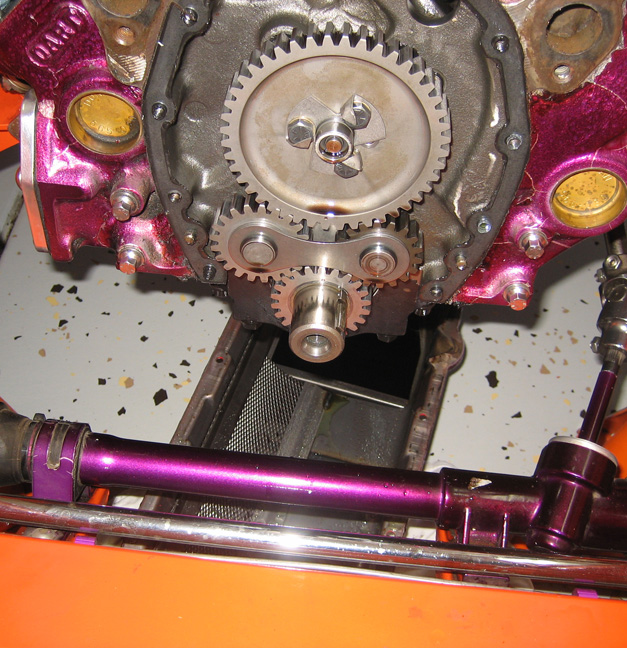

The next day I started the procedure of removing the camshaft. What does

it take to make that happen? It means I would have to remove the oil pan

(which is on the floor in this shot), the water pump, the radiator, the

bottom pulley and then the harmonic dampener would need to come off to

be able to remove the timing cover, which leads to the removal of the

timing set and then the cam can come out.

Now all this doesn't take that long, it's really the 'thought of

doing it' is what keeps me up at night. I also thought about taking out

the engine and be done with it but the thought of being under the car

for even longer, removing the entire exhaust system, the driveshaft, the

hydraulic clutch line and last but not least the transmission, I decided

against it. I figured if I found something else wrong along the way that

I didn't like once the oil pan was off, then I'd take the engine out.

Oh...remember at the beginning of the story about me changing the

oil? Well I didn't even go one mile on it. Once I removed the heads,

water filled some of the cylinders and once that happens, it will find

its way through the piston rings and into the oil pan. Antifreeze isn't

very kind to engine bearing material so I ended up throwing it all away.

And the filter as well :-[

|

|

|

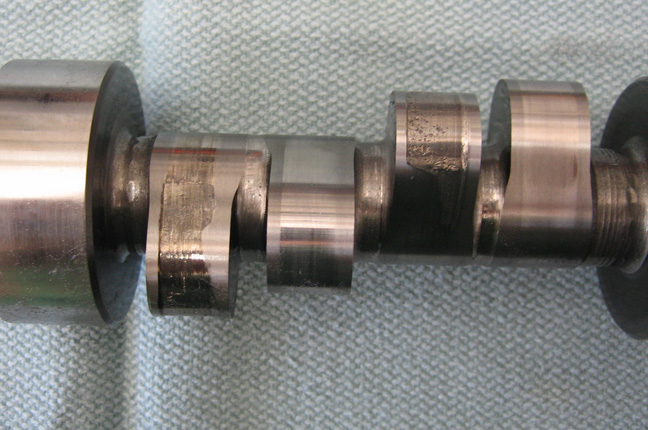

After a couple hours of disassembly, the camshaft was out. From here it

doesn't look that bad but if you come in for a closer look, that's when

things get depressing. Now if you had to guess how many lobes that were

bad, how many would it be? Read on to find out.

|

|

|

The two lobes that you see damaged here were really bad. But the ones

right next to them had normal wear and looked fine. Also note the deep

groove in them as well. I'm not sure what caused this but I'm pretty

sure the lifter failed first and wiped out the cam.

|

|

|

|

I'm gonna guess the reaction that you had as you were looking

at those pictures above was something like this: your mouth was open

making that "ooooohhh" sound, like when you see someone getting hurt and

you're glad it wasn't you. Well I don't blame you because it was painful

for me that's for sure. I ended up with three bad cam lobes in all, even

though I had four bad lifters.

I made a call to Iskenderian Racing Cams and talked to the same guy

that sold me this cam over 10 years ago. I told him my problem and he

said that they might be able to regrind my cam if the grooves weren't to

bad. He asked me how deep they were, but I didn't know so I told him

that I'd find out and call him back. So I went out to the garage and got

out my calipers to get a rough idea how deep the worst groove was. Now I

don't have anything to check the depth of the bad cam lobes compared to what Isky has, but I

think I could get close enough to know if it was savable or not.

The guy from Isky said that if the damaged area was .020 to .025 deep

then the cam was scrap. But if it was less than that, they could regrind

it to the same specs as before which gave me a little hope. I figured

the depth on the worst lobe to be .017 to .018 deep with my calipers. It was going to be

close.

Let me explain in a little more detail about all this: my cam is made

out of 8620 steel which has been heat treated or tempered. The type of

heat treatment for this kind of steel is called 'case hardening'. Case hardening is a process that hardens the outer surface of

the steel but the inner part is softer,

and is typical in the making of other engine parts like arbors, pinions,

king pins, ratchets, gears, splined shafts etc. can be made out of 8620

material and works very well. There are different depths to this type of

heat treatment which can vary from .010 to .080 deep. And in my

situation it looks to be an .080 case depth.

I called him back and told him what I found and after a few minutes I

told him I'd send it in for them to evaluate. The cost of the regrind is

about 1/3 the price of a new one so I didn't have anything to loose by

sending it to them. Now Isky also said they could rebuild my bad lifters

and the cost for that is about half price of a new ones. I packed one

cam and four lifters into a box and sent it to them.

A few days later he called me back and told me they found the cam to

be .019 to .020 deep on the worst lobes. Borderline at best. The procedure

here is that Isky would take my cam, regrind one or two of the worst

lobes, pull it off the grinder and then recheck the hardness of them. If

it checks good and into spec, that would be great but if it doesn't,

then it's no good and would be scrap.

I didn't think about this decision very long and told him to just

make me a new one so I didn't have to worry about it. This would give me

piece of mind and I had the option of using a cast iron cam gear on the

new one which they didn't have 10 years ago. The cast iron cam gear is

something they started doing a few years ago which means you can use

your stock distributor gear in place of using a bronze one like I had.

This was good news so I went with this option and I already have the

gear that came with my MSD distributor when I bought it new so that was

one part I didn't need to buy.

Now it's time to hurry up and wait so lets see what I've been doing

to keep busy.

|

|

1

2

3

4

5

6

7

8

9

10 |

|