|

New Tooling

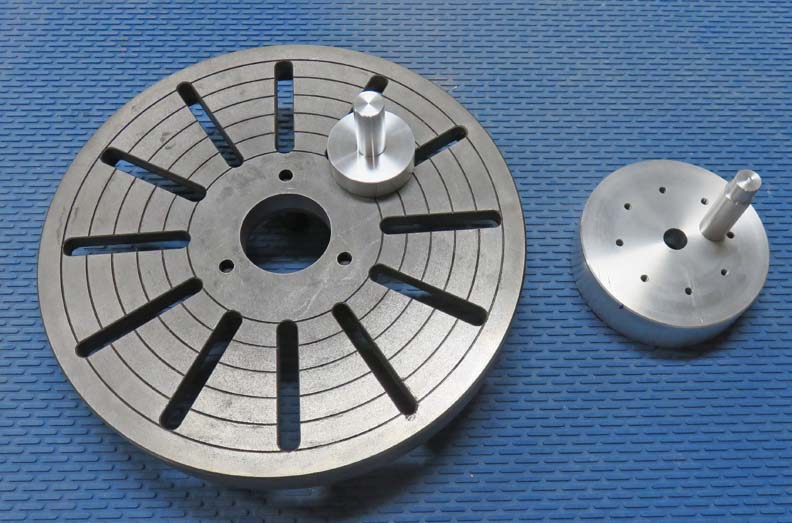

What you see on the left is a face plate that came with

my lathe. This face plate is just under 12" and it should work much better

than the one I was using previously (on the right). I checked the "face" of face

plate for run-out and to my surprise it was with in two ten thousandths

of an inch (.0002) which is really good. However, the center hole was

out by one thousandths (.001) so I bored it out to a nominal size and

then made a spud that you see resting on it. The smaller diameter on

the spud is 5/8" so it fits my work piece, which is the same as I had

before.

|

|

|

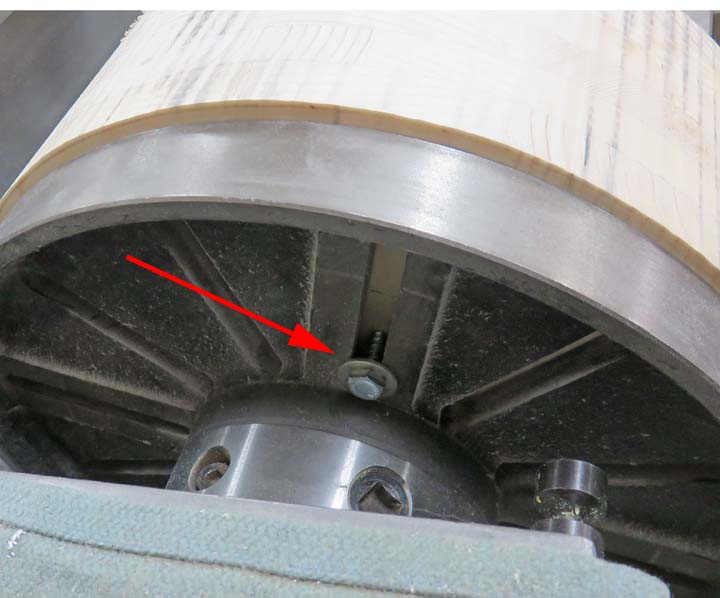

Here is what it will look like once it's

on the lathe

|

|

|

This will be a much better setup than before so my work piece has a

larger

surface to bank against. I was able to use the same spud with the live

center as I did before.

|

|

|

I switched to some 1/4" lag bolts to drive my work piece with which

worked out great.

|

|

|

|

A Small Problem

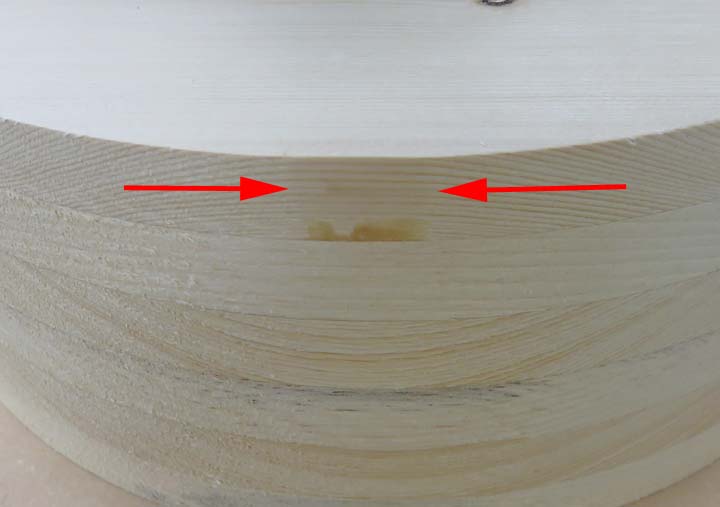

I had one piece that didn't clean-up 100% so I have to address this

without making a new one.

|

|

|

Here is the area that didn't clean up. Yes I know it's small but I want

this surface to be without voids.

|

|

|

I took my work piece over to the milling machine and removed a small

amount of material. Now it's time to add a piece back on.

|

|

|

I cut a small piece of the same material and glued it in place.

|

|

|

The next day I mounted it back on my lathe and machined it.

|

|

|

After a few minutes this is what I had. And if I didn't tell anyone

about it, no body would ever know once it was painted.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13 |