|

I've been asked to make a few things for my daughter and

son-in-laws business at Open Door Escape Games, to which I gladly

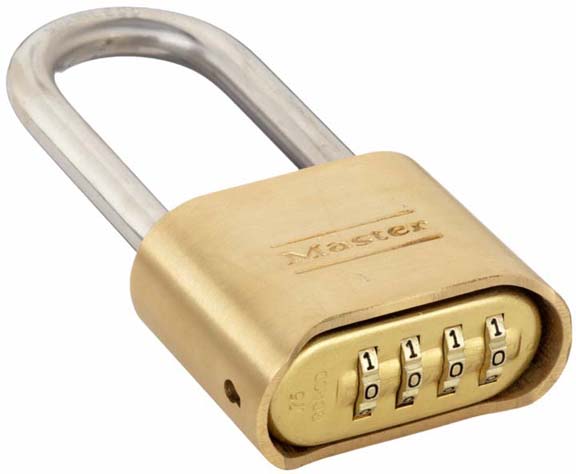

excepted. What I'll be making this time will resemble the dials on that

lock that you see below. However, I won't be making the entire lock,

just the four dials.

Now these dials will be made out of wood and each one

will be 12" diameter by 4 1/2" wide. Yes, that's pretty large but this

is what they wanted. And the dials will be mounted into some kind of

frame that will be attached to a wall, but the dials will only protrude

out from

the wall by about 2 1/2". Also, each one will have a tactile feel to

resemble a real lock, along with a sensor on each one. And once you get

each dial where it belongs, something happens.

Oh, one more thing, I'll be making a second set of these

dials that will be 12" diameter by 3" wide. This second set will be used

at a different Escape Room that my son-in-law has been hired to build

for someone. Yes, he's getting very good at this, along with all the aspects of construction

and I couldn't be happier for him.

|

|

|

Working With Wood

With all that being said, I'll be using common pine for

these lock wheels. However, to end up at 12" means I'll have to

glue two boards together because I'm not able to buy anything wide

enough for my needs. No big deal, it's just a little more time

consuming.

I've decided to glue a 1" X 6" and a 1" X 8" together to

end up at my target size of 12". In fact, these two boards will end up

at about 12 1/2", which will be perfect.

|

|

|

The first thing I did was run all the

lumber through my thickness planer just to clean-up both sides.

|

|

|

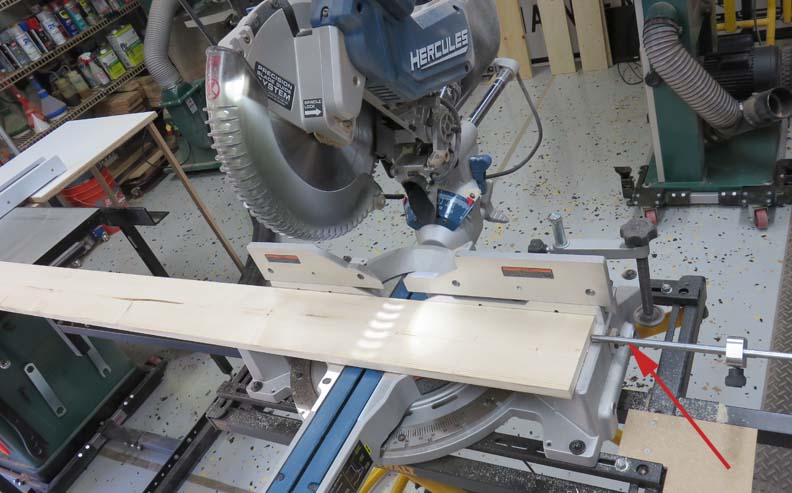

Next I cut each piece to 13" long. My saw makes quick work of this

process along with my home made work stop (arrow).

|

|

|

After I had my pieces cut, I ran them all through my tablesaw to joint

the sides that will be glued. Again, just a clean-up here.

|

|

|

Here is what my pile of lumber looks like now.

|

|

|

I recently bought two more parallel clamps, which came in very handy for

this project. This way I could glue and clamp two sets together which

really helped production.

|

|

|

The next day I sanded both sides with 80 grit to get rid of any step at

the glue joint.

|

|

|

|

Now The Fun Begins... Now it's time

to glue all those pieces I just sanded together. I'll need to stack six

of these pieces together to get the thickness that I'm needing.

Once I had glue on all

the

surfaces, my work pieces wanted to slide and move around making it that

much harder to work with. And it's a good thing I own two six inch

deep-throat Kant Twist clamps because none of my others would come close

to reaching the middle. I also used some aluminum plate on each side to

help distribute the load out more evenly on the Kant Twist clamps.

|

|

|

|

Some of this lumber was cupped pretty bad so I ran each

block through my thickness planer to help get them flat again. That's the good

news, but the bad news is they are now slightly under 4 1/2". But after

talking with my son-in-law he said that whatever size I ended up with

would be fine with him.

|

|

|

Next I laid out a center and then used my oversized homemade compass to

draw a circle.

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13 |