|

Working With Wood Continued

Here I'm using a 3/4" drill and going all the way

through. Notice the three pieces of wood underneath. These are made out

of MDF and the center one is used to drill into so there is a limited

amount of tear out. Twist drills like these are notorious for tearing the

wood when they exit your work piece.

|

|

|

Next I drilled two pilot holes for some

screws. These screws will be used to help "drive" my work piece when I

turn it on the lathe.

|

|

|

I used my bandsaw to cut near the line, leaving me a small amount of

stock to turn.

|

|

|

Her is a close-up of another one.

|

|

|

|

Making Tooling

Here I'm making a turning fixture for my lock wheels. The diameter is

about five inches which is the largest piece of tooling I had laying

around.

|

|

|

Here I'm putting in some holes, four are tapped and the others are

clearance for some #8 drywall screws. This fixture will help me turn my

larger pieces, along with some smaller ones that I'll show you later.

|

|

|

|

Working With Wood Again

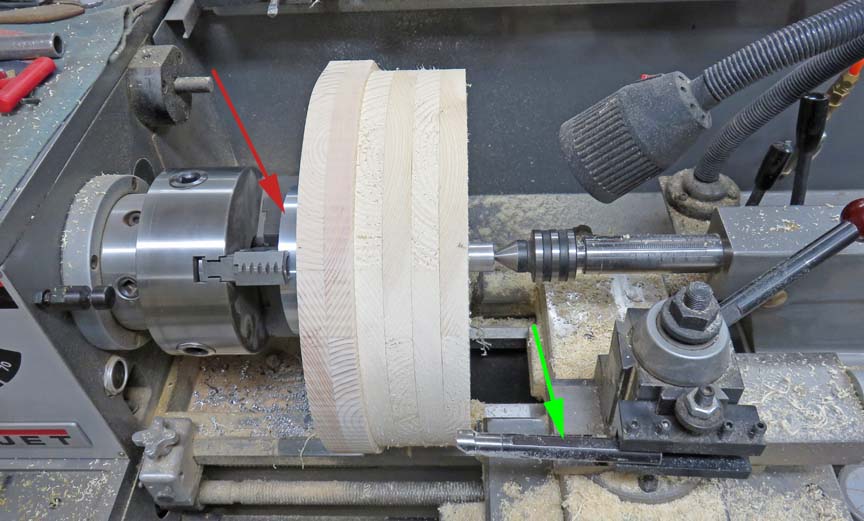

The red arrow is pointing to my fixture that I just made

which is held in my three jaw chuck. What you can't see are the two

screws going through my fixture and into my work piece. And like I said

earlier, these screws are used to 'drive' my work piece so I can machine

it without it slipping.

Also notice the live center on the other side of my work

piece. This is to help stabilize my work with the help of that

smaller aluminum piece in the 3/4" hole.

Now I wasn't able to use a conventional turning tool to

machine this large work piece, because it has exceeded the capacity of

my lathe. So what I came up with is NOT a normal way of cutting

something and if this were anything other than wood, I probably would

not have

attempted it. The green arrow is pointing to a boring bar mounted on the

outside of my tool-rest. Now this is the first time I've done something

like this but I had no choice because there was no other way that I knew of.

|

|

|

|

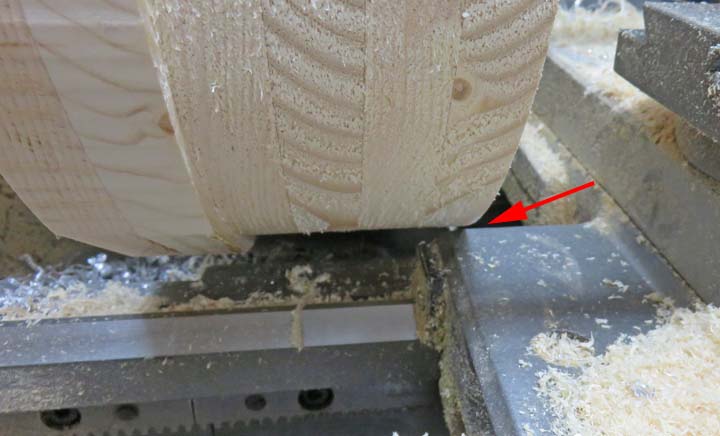

I wasn't able to use my power-feed like I would normally

because of clearance issues. So I had turn my compound rest parallel to

my Z axis and then use my cross slide to cut my work piece (arrow).

This method ended up working but it wasn't a very good setup I'll tell you

that.

|

|

|

The diameter that you see here is right at 12.00" and it's just clearing

my carriage (arrow). And as you can see I wasn't able to cut the entire

length either.

|

|

|

|

I switched to a longer boring bar which worked a little

better than the other one. However, I still had to use my cross slide to

cut the full length, which is not ideal at all. And once I had the

diameter that I wanted, I noticed that it had some run-out on the sides. That's not

good because I'll be making a trim-plate for this later and I want that

plate to ride as close as I can to the sides so you can't see behind it.

Time for plan B.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13 |