|

Working With Wood Continued

Here you can see the round pockets where I'll be placing the

stainless steel. These round pockets are 1/2" diameter and the slots are

1/8" wide X 1 1/2" long.

|

|

|

After looking at all the pockets and

slots, I decided to go just a little deeper on each one. Now everything

is 1/4" deep.

|

|

|

|

Working With Metal

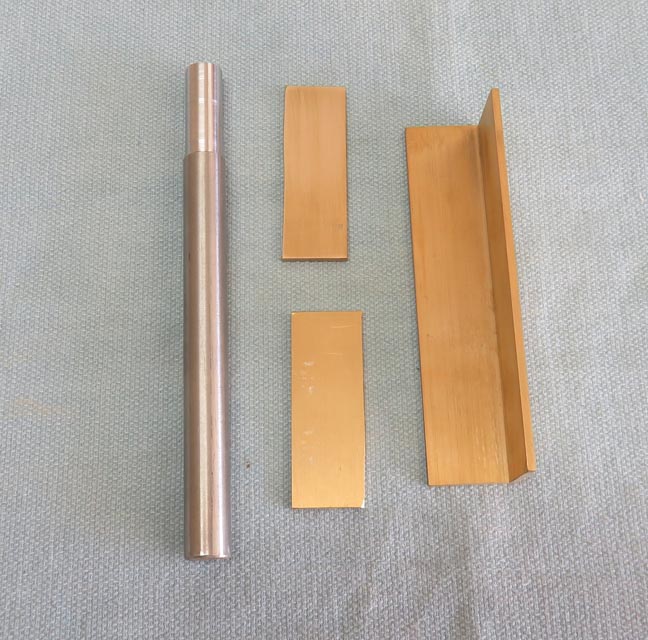

Here is the stainless steel and brass that I'll be using. Both of these

materials were leftover from a previous project.

|

|

|

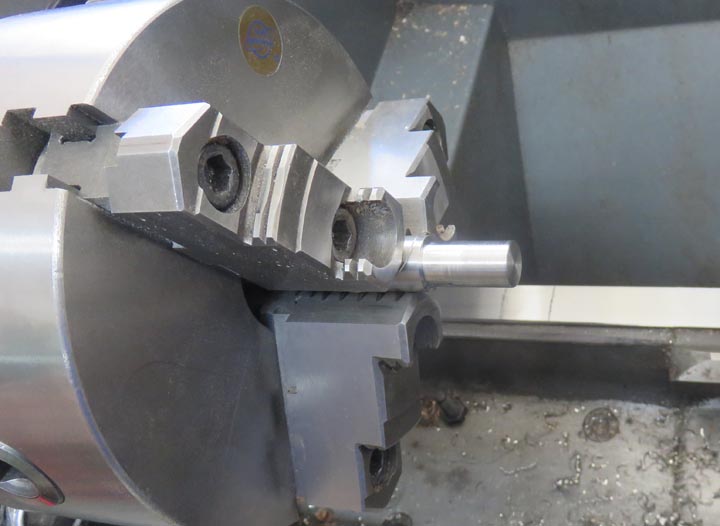

I machined the stainless to .500" and then sanded the ends to remove all

the machine marks before cutting them off.

|

|

|

Now it's time to machine the other end. And a keen eye will notice there

are nine pieces. This was in case I messed on up so I didn't have to go

back and make another one later on.

|

|

|

|

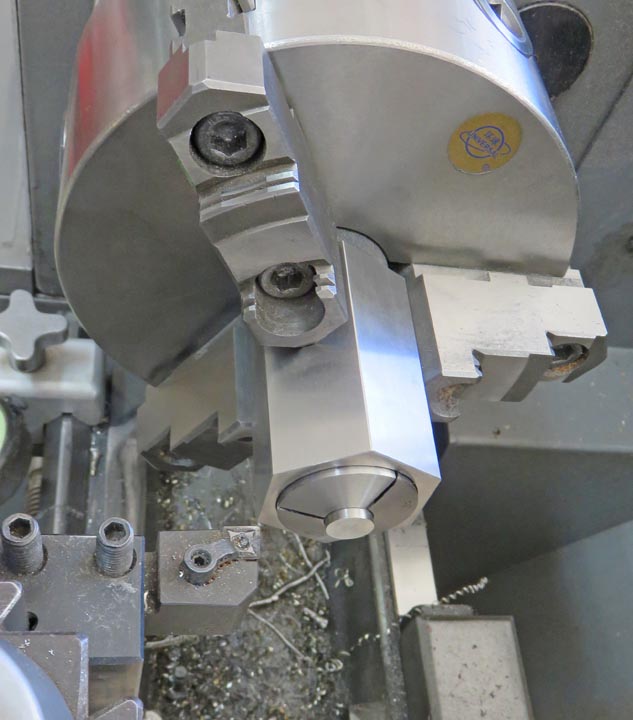

I'm going to use my 5-C collet holder to machine the

other end of the stainless pieces. The main reason for this is because I

don't have a work stop on my lathe and with parts this short, it's just

easier to hold them in a collet.

|

|

|

This hexagon collet holder should work great in my three jaw chuck. The

round black piece in back of the collet holder is a nut that tightens

down

the collet. And the spanner wrench tightens the nut.

|

|

|

|

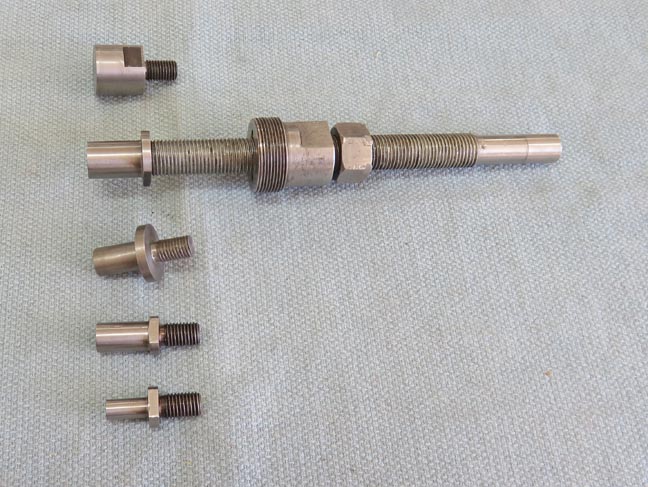

What you see below is a collet stop that I made many

many years ago. This only works with 5-C collets and is adjustable.

And I also made some threaded pieces of various sizes to accommodate

different diameter work pieces. The one that is threaded in the collet

holder is 1/2" diameter, which is what I need for my project.

|

|

|

|

The large thread on my collet stop threads into the back

of the collet (arrows). Then you can adjust the long threaded piece in

or out of the collet to whatever depth you need. Once you have the depth

set, you tighten the jam nut and you're ready to machine some parts.

|

|

|

|

Here is what the business end of the set-up looks like.

Now I can machine each part to the exact same length. But I have to

remove the hex holder each time I do that, which is no big deal for this

amount of parts.

|

|

|

|

1

2

3

4

5

6

7

8 |