|

Making More Clearance Continued

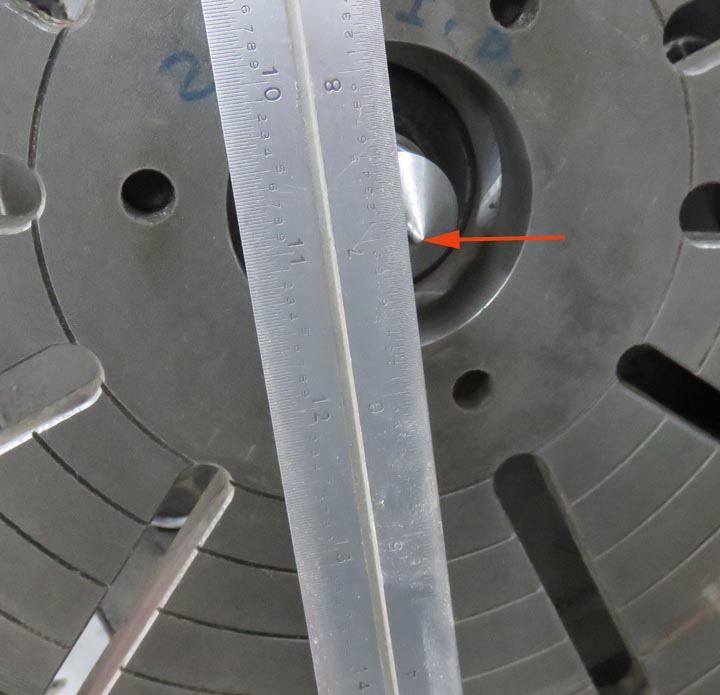

If you look close you can see the dead-center (arrow) is

almost at the 7" mark on my scale. This means I'll just clear my work

piece when I get ready to turn it. This is good news and means I can

continue with my project using my lathe.

|

|

|

| Making Tooling

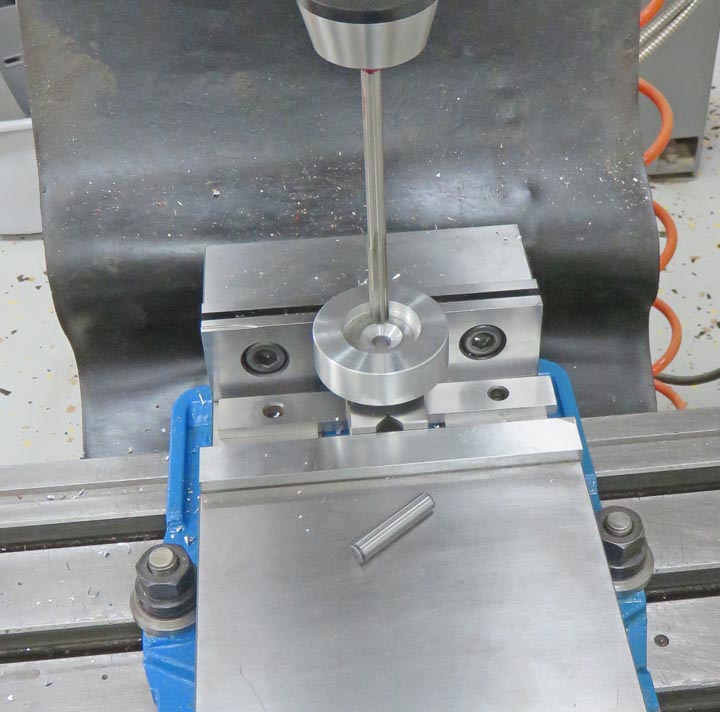

I drilled and reamed a 5/16" hole in this piece of tooling that will

go into my faceplate. I plan on using a 5/16" dowel pin in this hole.

|

|

|

And the other end of the pin will go into my work piece placing it in

the center of my faceplate.

|

|

|

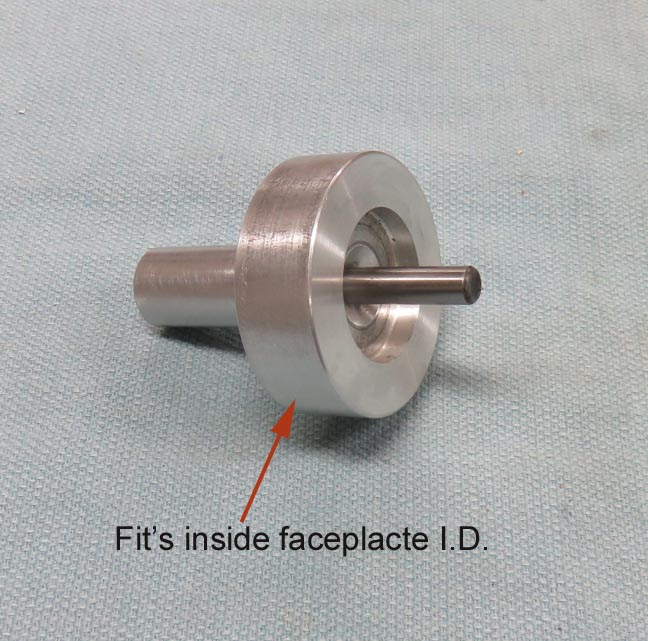

Here is what it looks like installed inside my faceplate. Now I'm ready

to start machining some wood.

|

|

|

|

Working With Wood Again

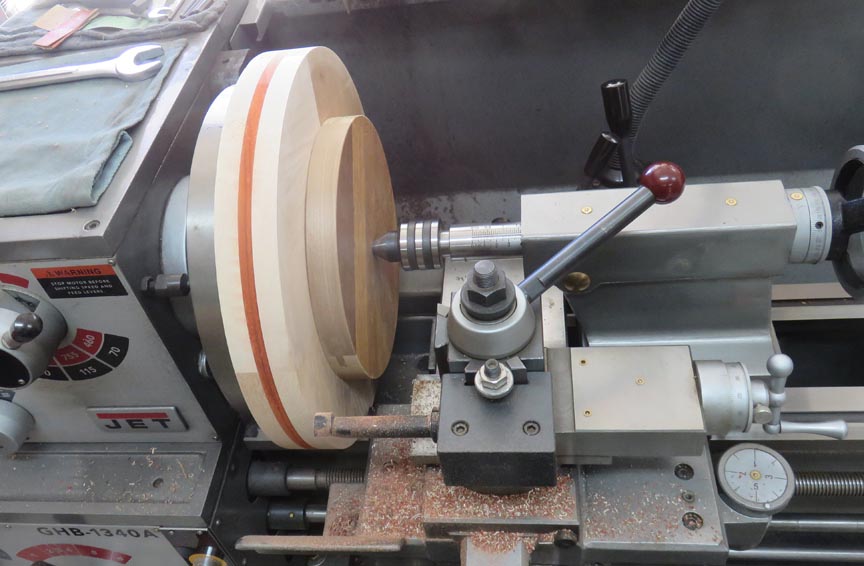

This is a similar setup that I used on a previous

project. With the use of that 8" diameter wooden piece that is being

pressed against my work piece, using my tail stock, this should provide

enough pressure to keep everything clamped in place while I machine my

new project.

|

|

|

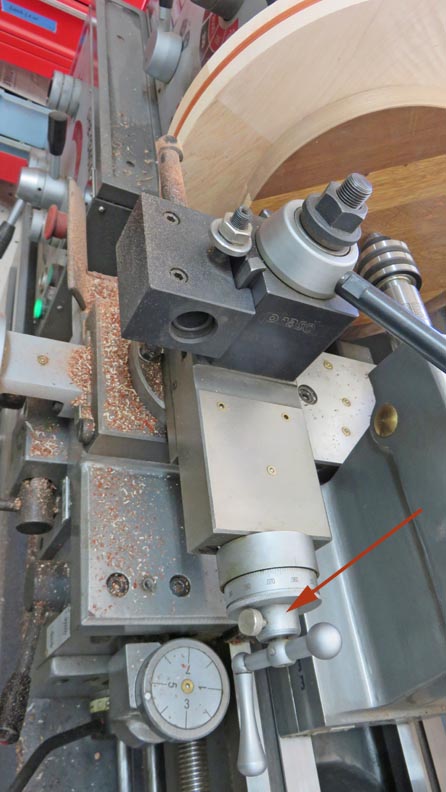

And like my previous project, I'll have to use my cross-slide (arrow) to

hand feed a boring bar to turn the outside diameter. This is

unconventional doing it this way, but it does get the job done.

|

|

|

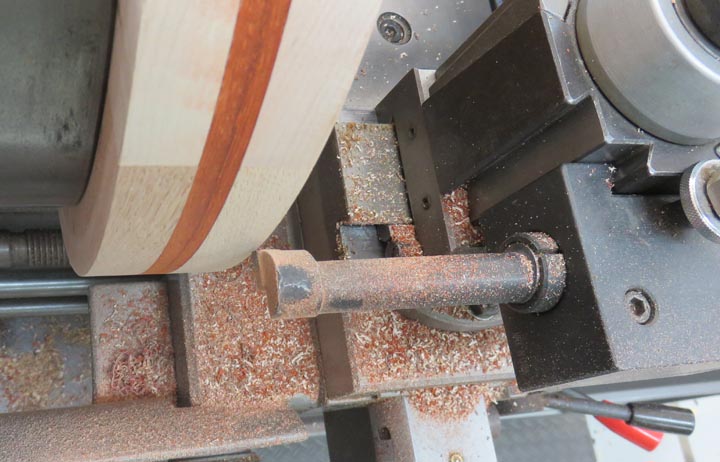

Here you can see my long boring bar sticking out with just enough travel

using my cross-slide to move across my work piece to turn the

outside diameter or O.D.

|

|

|

|

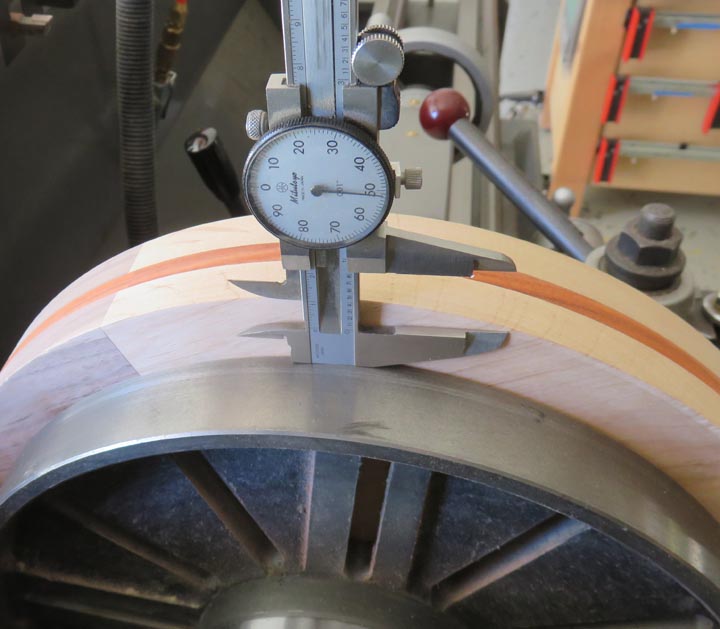

Now I don't have anything to measure the O.D. accurately

because the largest calipers that I have only go to 12". But I do know the O.D.

of my face plate and by measuring the distance from my work piece down

to my faceplate, I can calculate the diameter of my wooden piece.

|

|

|

|

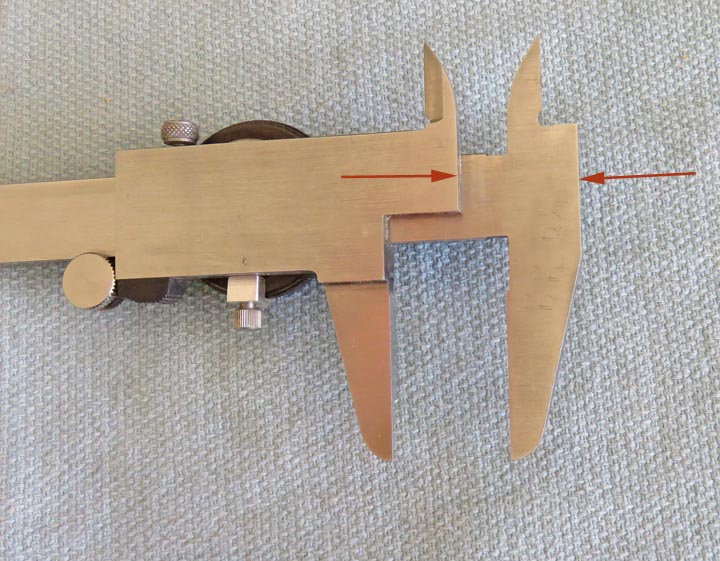

Most calipers have what's called '4-way measuring', which

are O.D. - I.D. - depth and what I'm using here called 'step'

(arrows). The step measurement on calipers comes in very handy, as you

can see. Now that the O.D. is at my target size of 13.5", it's time to

produce a recess in the face of my clock.

|

|

|

|

I'm recessing the face of the clock 3/8" deep and

leaving a 1/2" wide raised area around the face. To this I'm using the

same method as I before (using the cross-slide) but with a different

cutting tool.

|

|

|

|

1

2

3

4

5

6

7

8 |