|

Working With Wood Continued

Here is a close-up of what I'm doing. I had to stop at this spot

because I was bumping against my wooden clamp plate.

|

|

|

Now I need to remove the excess material in the center and to do that

I'll use my milling machine.

|

|

|

I set my tool depth and went around free-hand to cut out the remainder

of the material. This went fast and was easy to do.

|

|

|

Then I used my DA sander to remove all the cutter marks. But after

looking at it with everything sanded, I didn't really like it. I think

it needs to be a little deeper so back to the lathe we go.

|

|

|

I'm removing another 1/8" of material so my depth will end up at 1/2"

|

|

|

Back to my milling machine once again along with some sanding, and this

time I liked it. Yes it took some extra time but I think it looks much

better now.

|

|

|

|

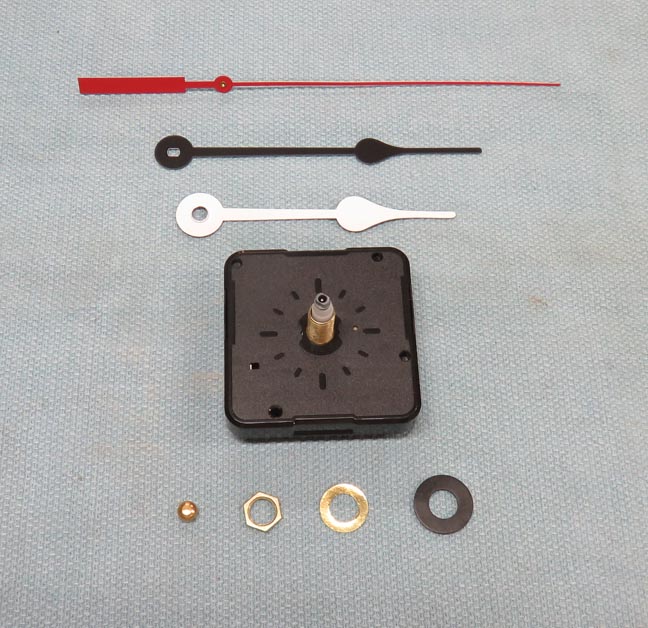

It's time to cut a pocket for the clock works. Now

I've used this type of clock works before and had very good luck with them so I'm using

it again. This mechanism has a sweep second hand that is silent and the

hour and minute hands are black on one side and white on the other. This

gives you options when your assembling.

|

|

|

I used a 1/2" end mill for the pocket which went nice and smooth. Now

it's time to turn the clock over and work on the face.

|

|

|

|

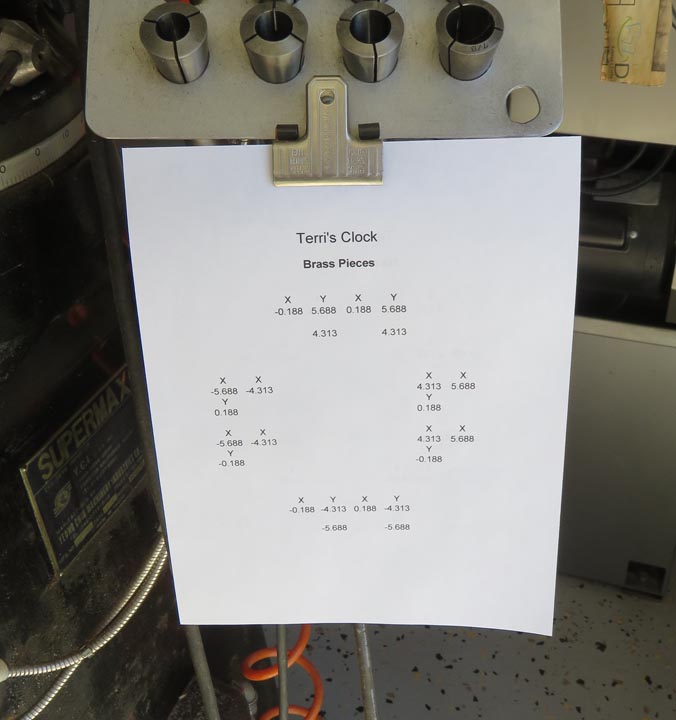

I'm going to use brass and stainless steel in place of

numbers. As you can see I've cut some slots for the 12, 3, 6 and 9

o'clock

positions below.

|

|

|

I have my cheat sheet attached to my collet rack.

|

|

|

1

2

3

4

5

6

7

8 |