|

Working With Steel Continued

I used a piece of wood under my three pieces of material

and then clamped them all down. The two pins that you see are only for

alignment of the three sheets because I previously machined the

perimeter of them all before hand. Once everything was clamped down, I

removed the pins and then cut out the center.

|

|

|

This didn't take that long and now all

there pieces have been machined. The sides are 1 1/2" thick all over.

|

|

|

|

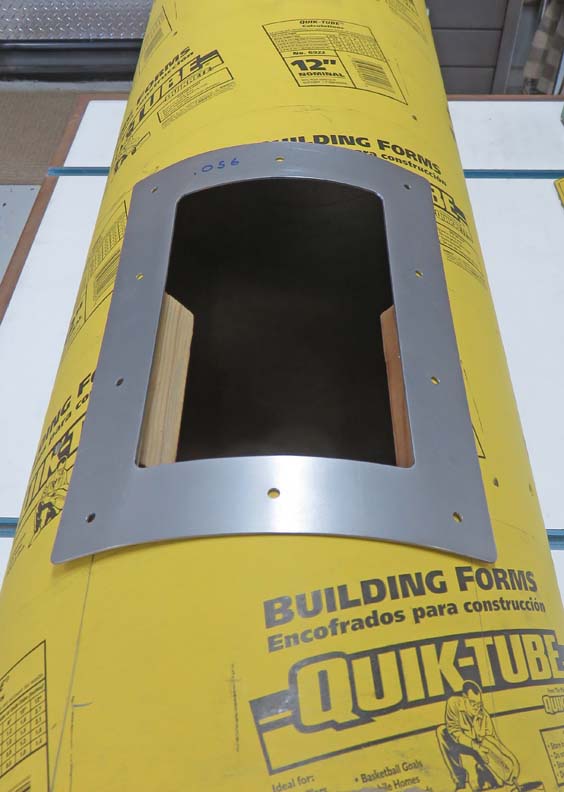

I used my razor knife to cutout the hole in the tube

which went pretty fast. The wood that you see in the tube are test

pieces. I thought that if we used four 2" X 3" or four 2" X 2" equally spaced

for the length of each tube, that would help stabilize things pretty well.

|

|

|

Here I'm cutting some acrylic that will be used for the window. My

bandsaw worked great for this.

|

|

|

Now it's time to pick a trim plate for the clear window. After thinking

about for a minute, I'm going to use the thicker material.

|

|

|

|

I needed the trim plate to conform to the tube so I used

the edge of my work bench to help form it. I placed the trim plate like

you see below, applied some pressure, moved my piece slightly and then

repeated. Slowly the trim plate was like you see here.

|

|

|

This only took about five minutes to bend and then I transferred all the

holes through the tube.

|

|

|

I drilled holes in the acrylic with the same bolt pattern as the trim

plate.

|

|

|

|

The acrylic is acting like a spring here, which is

keeping the

trim plate from sitting on the tube correctly. I ended up opening up all

the holes in the trim plate and window so everything would fit

right. I used nuts to fasten all the screws with, which was easily

accessed from the end of the tube. However, this won't be possible once

all the tubes are assembled. I need to figure out another plan here.

|

|

|

|

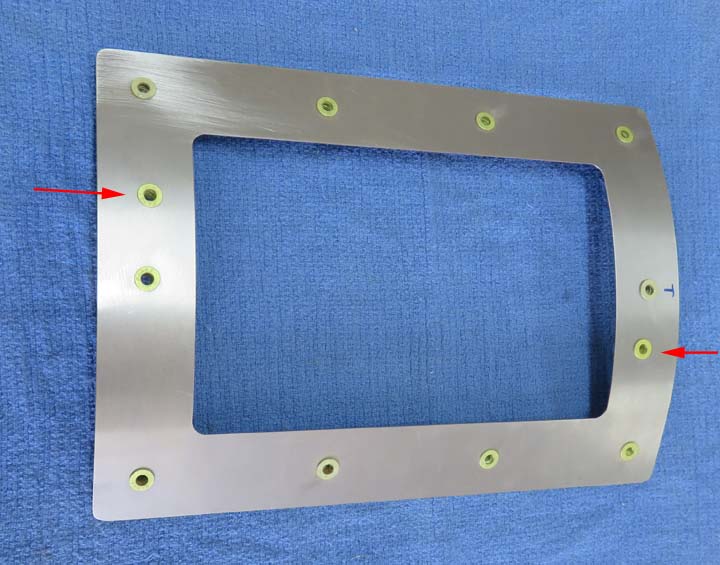

I remembered that I had some rivet-nuts leftover from

building my 33 Coupe years ago and sure enough, I had plenty of the #10

size that I needed. Rivet-nuts, or riv-nuts for short, have threads

inside them and squash or deform like a pop-rivet does. All you do is

drill the proper size hole for the riv-nut that you're using, then screw

a riv-nut onto your installation tool, then pull the handle. This deforms the

body of the rivet-nut and locks it into place.

|

|

|

|

I used the thinner trim plate for all my riv-nuts, which

worked out pretty good. However, I needed a way to remove all of the

screws on the outside without the inner trim plate from falling. Notice

the two arrows pointing to the those riv-nuts? These two riv-nuts will

be used with some flat head screws that go through the tube to hold this

trim plate in place so it doesn't fall. Problem solved!

|

|

|

1

2

3

4

5

6

7

8

9 |