|

Here is my cardboard tube again and this time I'll be making some rings

that go around it, four of them to be exact. Like I said before, the plan is to stack these

so they go from floor to ceiling. Now the height of the ceiling is about

10 feet, that means two full length tubes and one that will be cut to

size, about two feet long.

The rings will be made out of 1/16" thick mild

steel sheet, then bent and welded together. These rings will be placed

at each tube joint to help hold everything together. The bottom ring

will be six inches tall and will be attached to the concrete floor. This

way it will make sure the tube won't move and stays stable. The top ring will attach to

the ceiling and will be two inches tall. There will be two middle rings

that will be four inches tall and they will join the top and bottom

tubes together. And last, these rings will also

have large bolts welded in them to help simulate the construction, but

really won't be functional.

|

|

|

| Working With Steel

Here is the 1/16" mild steel sheet that I'll be using. The

two square pieces at the top are going to be base-plates for the top and

bottom rings. The base plates will be round when finished. The rest of

the material, is for the rings.

|

|

|

|

Here I'm cutting out both bases at the same time using my jigsaw. To make

sure they stay together I'm using some clamps that I move when needed.

Once they were cut out, I used my belt sander to remove all the sharp

edges.

|

|

|

|

The next part that I'm doing is putting holes in all the

rings for the bolts that I mentioned earlier. What I need to do is put

eight holes in each ring that will be equally spaced apart. However, the

four inch wide rings will have 16 holes in them (two rows of eight).

|

|

|

|

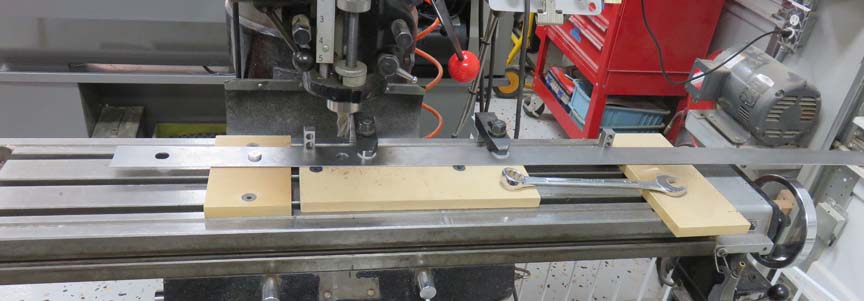

I made an aluminum pin that is two to three thousandths

smaller than my milling cutter. Then I used that same milling cutter to

produce a hole in the piece of wood that you see below (the pin is a slip

fit now). I also bolted that piece of wood

to the mill table so it wouldn't move with some flat head screws. With this

setup, I can machine one hole

in my work piece, loosen my clamps, move my work piece over and have

that hole locate on my aluminum pin (which is a calculated distance) so they're

all equally spaced when I'm done.

|

|

|

|

Here I'm trimming my material two inches oversize. The

reason I'm leaving it oversize is because when I form these into round

pieces on a tri-roller, the material doesn't form well when it exits and

leaves a small flat area. Once I'm finished with the tri-roller, I

can trim off this excess material leaving a nice round work piece.

|

|

|

Here is what my pieces look like with all the holes in them. The two

inch piece at the bottom has been cut slightly oversize but the others

have not yet.

|

|

|

|

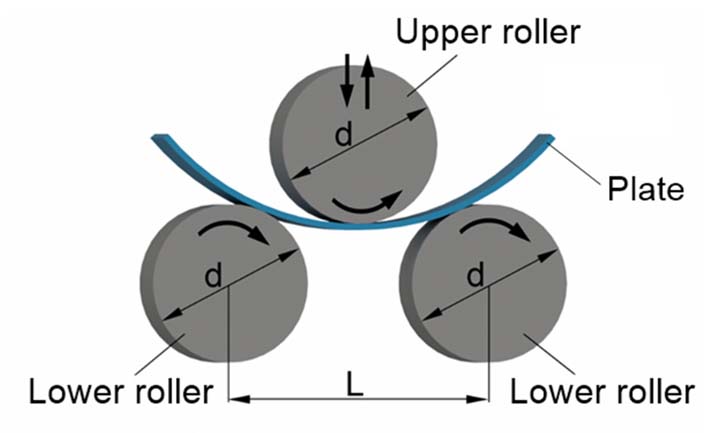

Here is what a tri-roller looks like. It has three

rollers, (hence the name tri) and is adjustable to form different size

radii and thickness' of material, depending on your needs. Now this isn't the actual tri-roller that

I used as I forgot to take a picture of it while using it at my old

work. And some tri-rollers are motorized, because as the material

thickness increases, so does the friction making a hand crank useless.

|

|

|

|

Here is how a tri-roller works, you feed your material

into one side and then crank the handle. As you crank the

handle, it drives two of the three rollers feeding your work piece

through them. The third roller is adjustable fore and aft, allowing you to

adjust your radius size. It's a simple design that works very well.

|

|

|

After about 15 minutes on the tri-roller, I had all my rings formed. Now

it's time to trim off the extra material I left on there.

|

|

|

|

1

2

3

4

5

6

7

8

9 |