The fuel system is going to consist of

two different types of fuel lines. One will be 1/2" diameter

aluminum tubing and the other will be #8 AN braided steel line. The

aluminum tubing will be used to run along the frame rail under the car

while the braided steel will be used in the engine compartment and then

connect to aluminum. I'll also be using the braided steel line to go

from the fuel cell, which will be mounted in the trunk, down to the

frame where the aluminum tubing is. Installing the fittings are hard to

do but looks good when your done so I hope nothing leaks. This is a

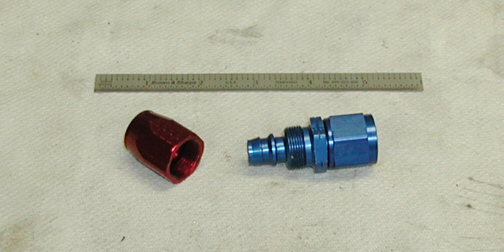

Swivel-Seal hose fitting made by

Earl's

for the braided steel line. It has threads in one end for mating with

other #8 fittings and the hose gets assembled in the other.

|

|

|

The hose that I'm using is also made by

Earl's and is called

Auto-Flex. Earl's makes another type called

Perform-O-Flex which is a grade above the one I'm using but much more

expensive. The first thing that has to be done is

to cut the hose. The way you do that is to place some tape (electrical

or masking) around the area that will be cut and

then cut through it. I used a Dremel with a thin cut-off wheel which works

good, but you could use a hack-saw with a blade that has 32 teeth. Now

you trim any loose or frayed ends that might be sticking out with some

wire cutters.

|

|

|

These two pieces screw together to

make a hose connection. The socket (red part) goes over the end of the

hose first which is easier said then done. You have to work the end of

the hose a little at a time till you get all the loose ends inside the

socket. I used a small flat screwdriver to help insert all the loose

ends. If your not bleeding at the end of this procedure, you did good!

The ends of the braided steel hose are not very forgiving. The other end

is called a nipple (blue piece). You can see the barbed piece on the

small end that swells the hose and the socket tightens against all this

to make a seal.

|

|

|

Once the hose is inserted into the

socket, you have to make sure it isn't to close to the threads. You want

about 1/16" to 1/8" of clearance between the two before

inserting the nipple. At this point, I make a mark on the hose next to

the coupler with a red Sharpie marker to see if the hose has moved once

the two have been assembled.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 |