|

Working With Wood Continued

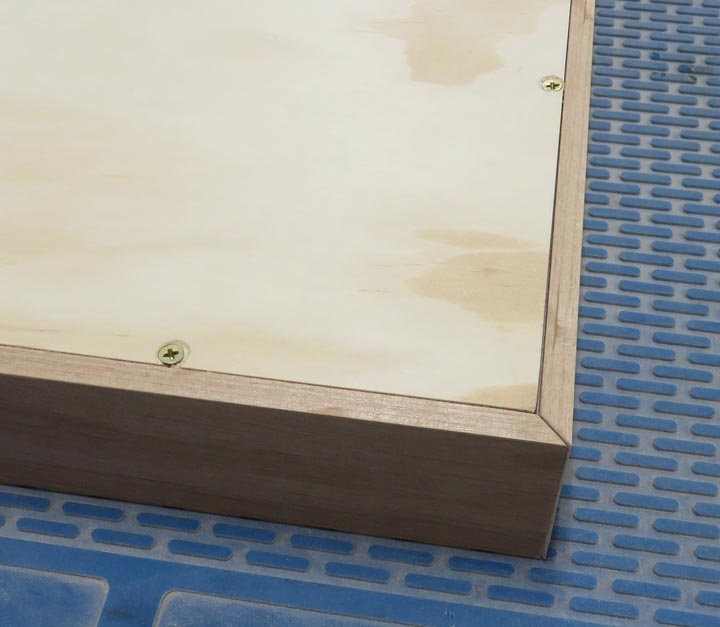

Once I was happy with the fit, I drilled all the pilot holes for the

#4 screws.

|

|

|

If you look close, you can see the

flathead screws are at a slight angle. I did this because the wall

thickness was very thin in this area. No big deal as I just made the

countersinks deeper to compensate.

|

|

|

|

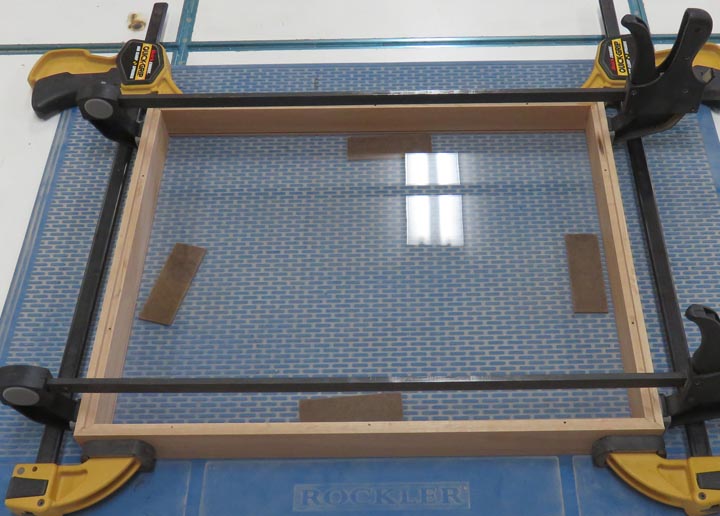

Now it's time to glue the frame together. I applied two

coats of glue to the mitered corners knowing that end grain doesn't glue

together very well. Now I've used this method before and had good

results so this should work pretty good. However, I've never had to glue

a frame together with a clear piece inserted at the same time (glass or

plastic as I'm doing now). So to help me keep the plastic at the correct

height I used some wooden shims that were 1/8" thick under it. These

shims kept the plastic in the right position as I joined all the corners

and then clamped everything in place. Plus these shims are made out of

wood so they are more forgiving on the plastic than then steel ones I

used before (when the protective layer was on the plastic).

|

|

|

|

The hardest part about doing the glue-up this way was to

make sure the glue didn't get on the plastic anywhere. Well, it did in a

couple of places but I managed to clean it off with a wet towel before

it dried.

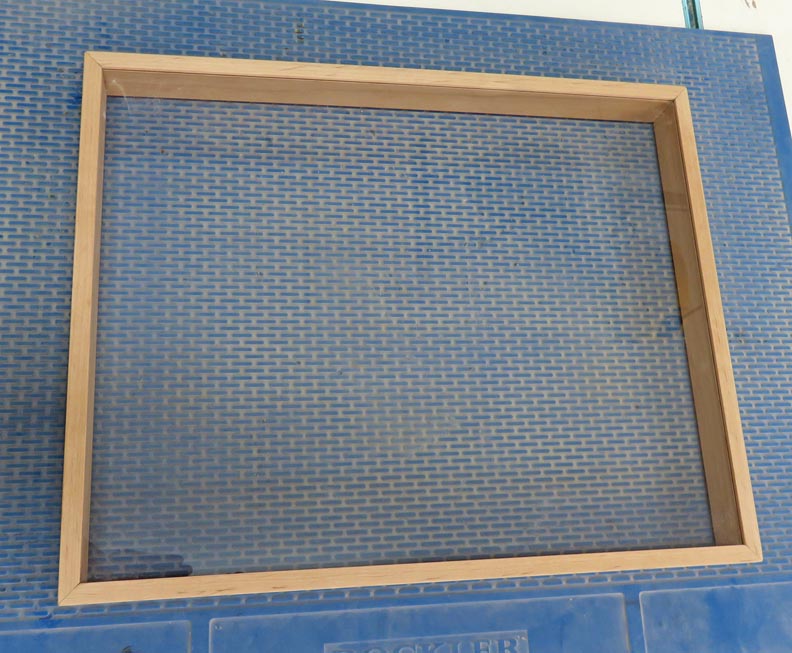

Like I said before, this type of glue joint isn't very

strong so that got me thinking on how I could strengthen the corners?

Splines!

Yeah that's it..."splines". Because if you add some

splines to each corner, they will end up making the frame much stronger.

But I don't have a jig to put splines in a frame. Looks like it's time

to make one then.

|

|

|

|

Let's Make Some Tooling

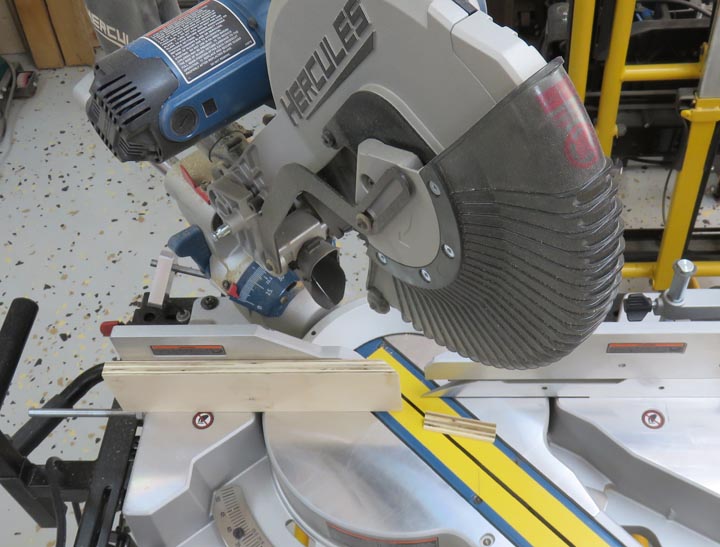

I'm going to make a spline jig out of some 3/4 plywood. Here I'm

rough cutting some pieces on my bandsaw.

|

|

|

Then I used my table saw to bring all my pieces to size.

|

|

|

The large piece is 15" square, the middle piece is the width of my

tablesaw fence and the last piece is 3 1/2" wide.

|

|

|

I also cut two more pieces that were 3" wide by 12" long that will

become the cradle that holds the frame. I'm also putting a 45 degree

angle on one end. I'll show you why on the next page.

|

|

|

|

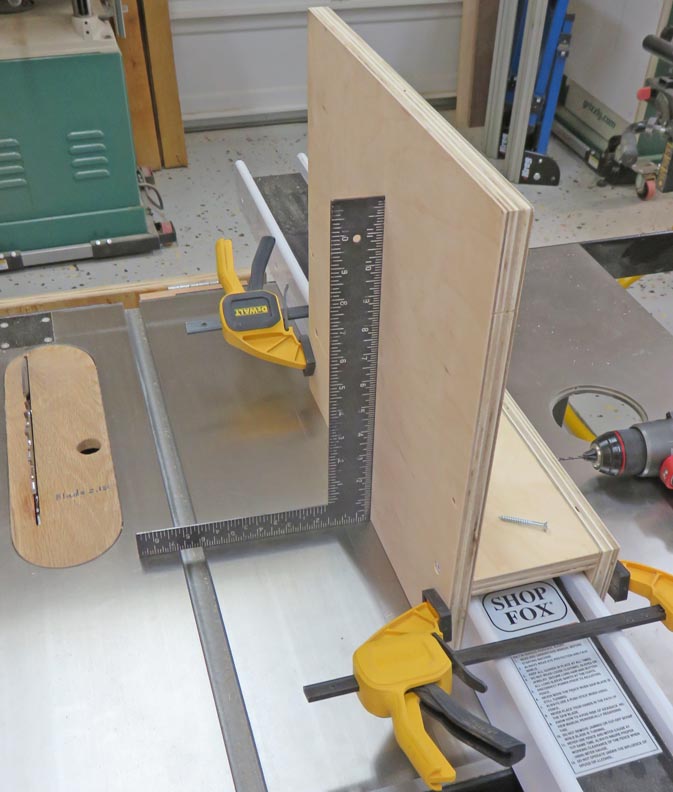

Here I'm screwing my assembly together. Notice the

center piece that goes across my tablesaw fence. I measured my fence,

added about .010" and then cut my piece. This extra .010" should give me

just enough width so when everything is assembled, the whole unit will

side without binding.

|

|

|

Here I'm squaring up the front side before I put in all the screws.

|

|

|

|

1

2

3

4

5

6 |