|

Working With Steel

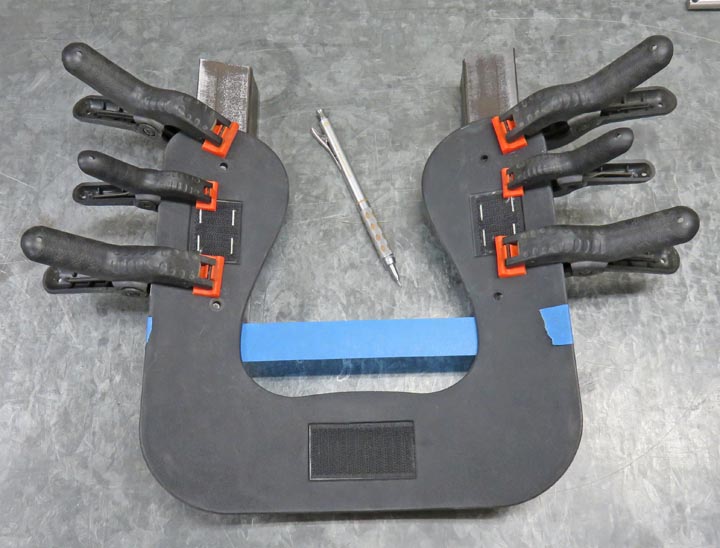

Here I'm transferring the hole location from the plastic

to the angle iron. On the bottom side I marked some lines on the blue

tape to aid me in lining things up. Then with the angle iron clamped in

place, I marked my hole location with a pencil because a Sharpie

wouldn't work for this.

|

|

|

Then I used my center punch to make a dent

in the center of each pencil mark. I used my hand drill to put holes in

this material which wasn't that easy because of how tough it was.

|

|

|

Once the holes were in, I used some 3/16" diameter rivets to keep things

in place while I worked with everything. However, I didn't set the

rivets, I just used them temporarily for now.

|

|

|

|

Here I'm removing the height from one side of the angle

iron (arrows). The first reason

was for weight, and second is because this side is mostly unused, so why

not. After machining I deburred all the edges and was ready to make

another piece that will be welded to this one.

|

|

|

|

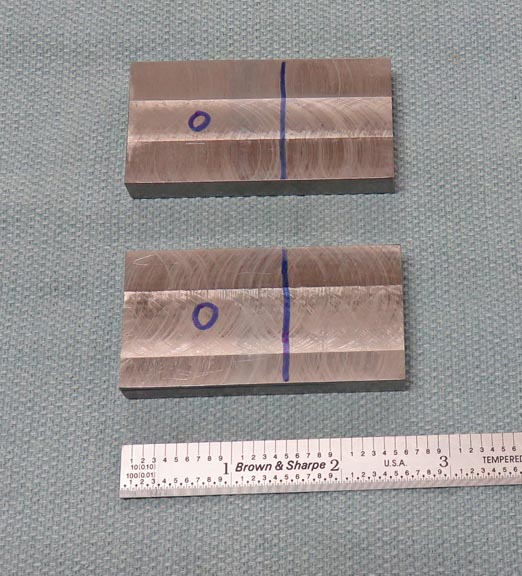

I had these two pieces laying around and thought they

would work for this project. these pieces will end up with a 3/8" hole

(about where the layout mark is) and another 1/4" hole that will be used for

some pins. The blue line is where I'll be cutting them off at.

|

|

|

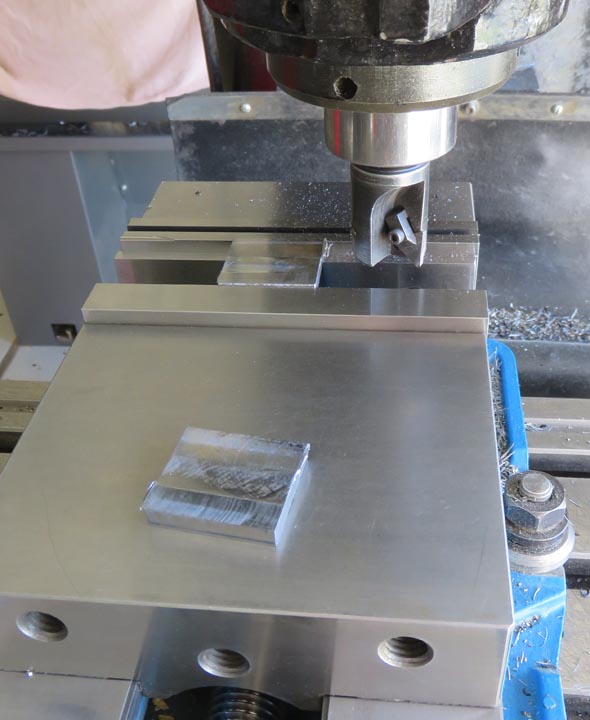

Once I had my pieces cut off, I used my milling machine to reduce

the thickness. I also machined all the other sides as well.

|

|

|

|

I'm using some shoulder bolts that will be used as the

pivot points for this headrest. This is the area that will fold down when

the headrest is not in use. If you're not familiar with this type of

bolt, these are used in the mold making and die making industry (machinist world). Normally

the ground diameter (shinny area) would go through a very stiff spring

and would be used to retract some kind of plate so the part doesn't

stick to the punch (this would be in a die making scenario). Anyways, I

won't be using any springs but this will be perfect for my application. I'll

talk a little more about shoulder bolts soon.

|

|

|

|

After finding the exact spot I needed for the shoulder

bolt, I drilled my 3/8" hole. Now normally I'd put something like this

in my vise to hold it, but with the angle iron not 90 degrees any longer, I just

clamped it to my mill table with some wood under it and drilled my work

pieces. This was a little more work doing it like this but it's really no

big deal.

|

|

|

|

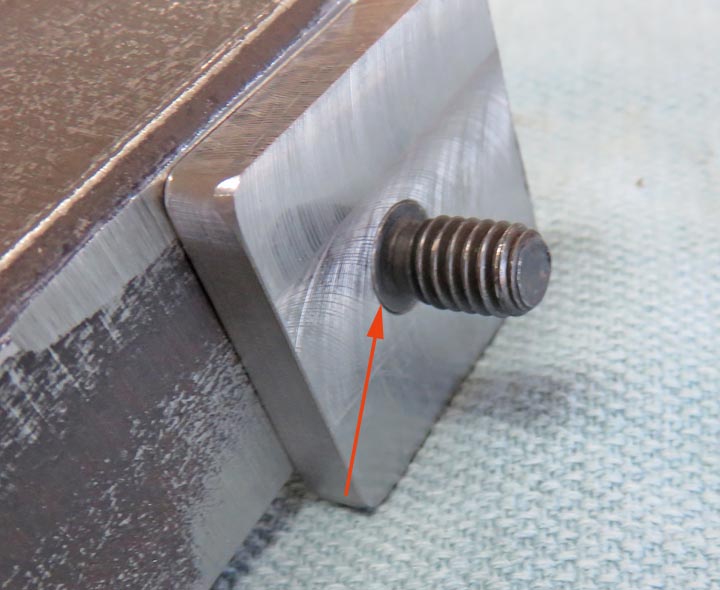

Notice the end of the shoulder bolt is just above the

surface (arrow). With this design, you can tighten the bolt and nut down

but it will still allow those pieces to move. With that being said, this

will give the headrest the

ability to move 90 degrees, or fold down out of the way.

|

|

|

|

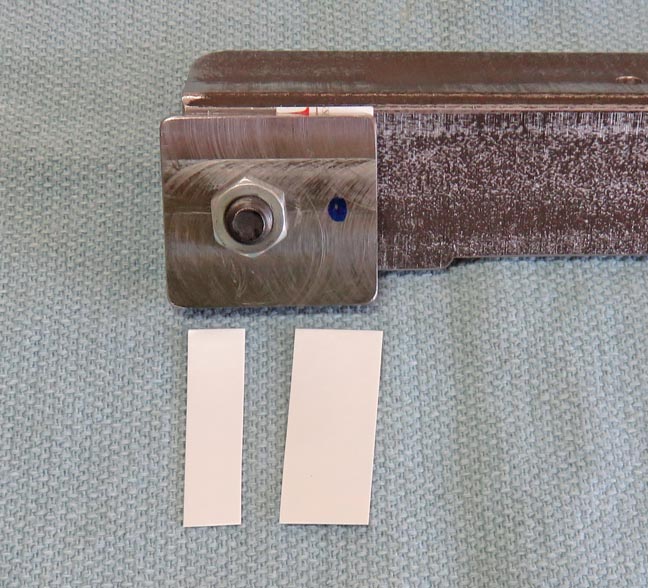

Now it's time to drill the 1/4" hole for the

locking pins. And to be able to drill though both pieces and still have both holes

line up correctly, I'm using some paper shims that will go between the

movable pieces. The paper will act as spacers so when the nut and bolt

are now tightened, the two pieces won't move while I'm machining.

|

|

|

|

1

2

3

4

5

6 |