|

I used my height gage to the find center on the steel pads and scribed a

line on each one. Then I clamped each pad to the gear making sure I

lined up both lines with each other.

|

|

|

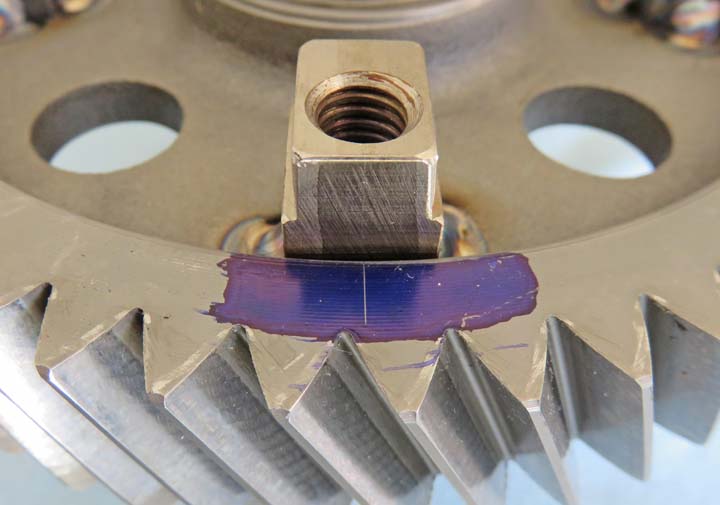

I forgot to take a picture of the clamped

pads in place but here is one I just welded on. It's hard to see the

line now that heat was applied but if you

look close you can still see it.

|

|

|

And there we go, all the pads are in place. This was an easy way of

aligning something and now I know they're in the right place. All this

for something you won't see because it's on the bottom.

|

|

|

Here is what it looks like with all the feet bolted on. This should give

the lamp base a unique look.

|

|

|

The distance between the two arrows shows you the amount of clearance I

have to play with in case the base doesn't sit flat. If it doesn't sit

flat, I can machine off a small amount so it does.

|

|

|

So far I'm liking these feet because they move enabling them to sit

better on an uneven surface.

|

|

|

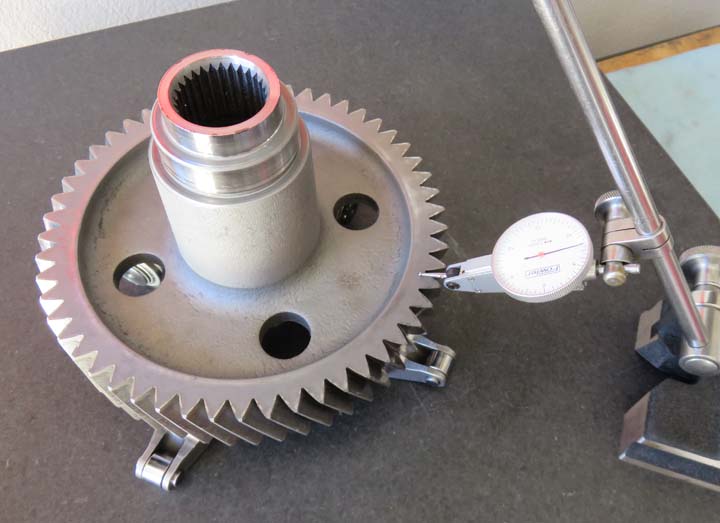

Speaking of sitting flat, I set the base on my surface plate to do some

checking.

|

|

|

|

I was pleasantly surprised with what I found, I only had

.007 TIR (total indicator runout) while checking with my indicator

around the gears surface. That's not to bad without any machining!

This got me thinking, what angle would lamp be at once the cam was fastened to it? I mean, the camshaft

plus the base and light are going to be close to 35" tall when complete.

And being that tall would make it easy to see if it were at an angle or

not. After doing some quick trigonometry, the angle was much

less than I thought (less than a 1/2" degree) so I'm good.

|

|

|

|

Electrical and Final Assembly I bought some lamp hardware not knowing exactly what

I'll need but one thing I did want was a pull chain. As you can see the

make-a-lamp kit didn't come with one so I added that. Once I started

looking at all the lamp parts I came up with a plan to attach it to my

camshaft.

|

|

|

|

I made an adapter out of aluminum that is 2" diameter X 3/4" thick. I

put some grooves in it just to be fancy. I also drilled and tapped 1/8-27

tapered pipe threads in the center for the lamp hardware. Why not

straight pipe threads? Because this was the only tap I had and after

trying it on a scrap price, it worked great.

|

|

|

|

1

2

3

4

5

6 |