33 Coupe Adjusting and Tweaking 10

4/16/08

|

I worked on the car the following week

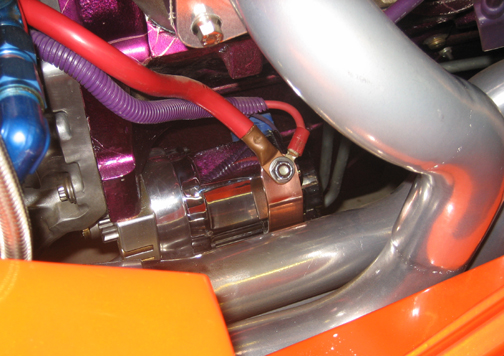

(now that I had more time) and was able to install my fuel shut off

valve, and relocate my battery too. The reason I moved my battery was

because I made a new tray for it out of aluminum and some of the pieces

I had anodized. While I had the

battery out, this would give me a chance to install my new starter as

well. I had thought about removing my old starter,

taking it all apart and then sending some of the pieces to the chrome

shop. The reason for all this was because it's easy to see. After

checking out how expensive chrome is these days and how much work it

would be to disassemble and reassemble it, I ended up just buying a new

one. The new one is the same model as my old one, but it's chromed. And

being that they're made by the same company, I would be able to use my old mounting

block that had already been modified (clearanced for my headers).

This is my new one and it looks a lot better. I also took the time to

shine up my copper battery cable extension too. In case you're wondering

about the copper extension, I made it awhile back to move the battery

cable away from the hot headers. It's about 3 1/2" long and has two

bends in it so it wraps around the starter. If the cable was connected to the

starter, it would have melted years ago because it's right next to those

header tubes. I'm not sure how anybody else does this, but it worked for

me.

|

|

|

My battery tray that I made from angle iron awhile back

served it's purpose well, but I was never really happy with it. I guess

I knew deep down that I could do better, which is probably why I started

making a new one a few months ago. I was in no rush to finish it because

I had one that worked, but as the week went by, it was on my short

list of things to do now.

|

|

|

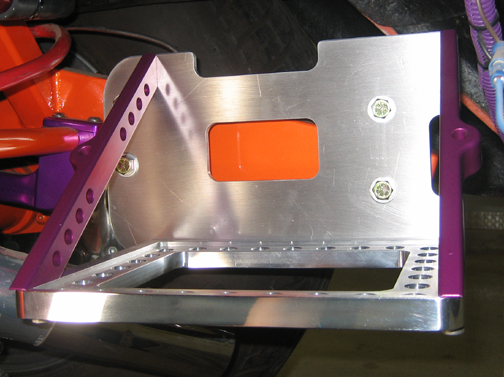

| The new one is made from aluminum (billet). In case

you've ever wondered what "billet" is, it's really very simple because

it's any metal that starts off in a solid form (round or flat stock for

instance).

Once you machine it to what you want, people say that it's made out of

"billet", which is true, but "any" metal in it's solid form can be

called that. So the next time you here the word "billet", it's really no

big deal and doesn't mean that it's the best material on the planet,

it's just a piece of metal that came from a solid piece. And in my case,

it's

6061-T6 aluminum.

The battery sits in a 1/8" deep recess that has been milled into 5/8"

thick base. Notice the two holes in the middle of the supports, these

are for the bolts that will hold down the battery that have been

incorporated into them. I also moved the location of the battery towards

the rear of the car about 1 1/2" and down 3/4". The reason for the move

was to give me more clearance between the top of the battery and the

underside of the car, and it worked out pretty well.

|

|

|

I used my existing four bolt location to fasten the unit to my chassis,

and all the holes in the base are for lightening. The base is fastened

to the back piece (which is 1/4" thick) with four 5/16 bolts (which you

can just see if you look close) and the same size screws are used to

hold the supports on too. In this shot, the exhaust looks closer to the

tray than it really is.

|

|

|

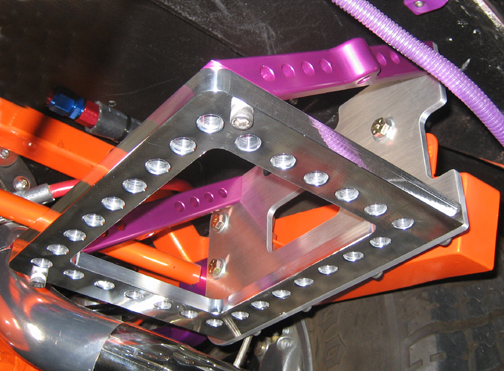

Here is the hold-down clamp that I made to keep things in place. The piece

is 3/4" X 3/4" X 11" aluminum that has been notched out (L shaped)

underneath to fit my battery (which you can see on the left side if you

look close). The bolt hole area has been milled away so the

bolts sit flush with the top.

And the bolt holes have been placed right next to the cut out area so

the head doesn't turn when I tighten the lock-nuts. Every edge has a

1/8" radius on it so it looks a little better too. On the other hand, I

don't think to many people are going to see it, but I had fun making it.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14 |

|