|

Working With Metal Continued

The one on the left is the original and the one on the right has the

larger chamfers. I modified four hinges, which will be used on two of

the boxes. The other two boxes will have the smaller screws.

|

|

|

Here is a look at some of the screws that

I wiped out. Turns out they were very soft, but they held up long enough

for me to put threads in each work piece, so it wasn't a total loss.

|

|

|

|

Working With Wood Again

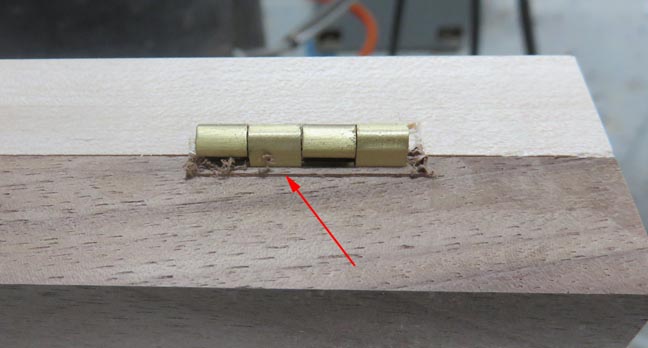

After getting all the hinges installed, I had a slight

misalignment with the top and bottom pieces matching up correctly. What I

decided to do is cut the mismatched box with the hinges installed which

worked out just fine, and it insured me that everything would stay

aligned by doing it this way.

I'm using a 1/2" end mill to machine the two haves of

the box, but I'm staying away from the brass hinges.

|

|

|

The arrow is pointing to the area that I didn't cut, which was

about .010" high. I'll revisit this area later on but for now, it's

time to soften some of the edges.

|

|

|

I left all the edges pretty sharp knowing that I would address them

later.

|

|

|

I wouldn't want a box with these edges and I don't think anyone else

would either. So it's time to address this.

|

|

|

This is a plastic box that I've owned for 30 plus years and has 12"

calipers inside it. Notice the corners and the other edges.

|

|

|

This type of box is easy to carry, move, open and feels good in the

hands. This is something I'm use to and I'm going to be doing something

similar to my boxes.

|

|

|

I'm using one of my radius gages to layout a pencil line at all the

corners. The size of the radius is 3/16". I used my belt sander and

sanded to the line.

|

|

|

Next I used my router table with a 1/8" radius to soften all the edges.

|

|

|

|

1

2

3

4

5

6

7

8

9 |