|

Working With Wood Continued

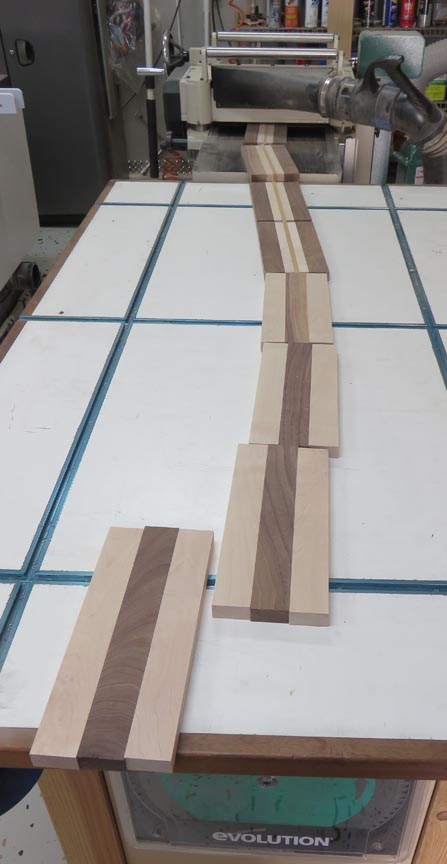

Here I'm gluing up four pieces that will used for the bottom of the

box. There is no glue between the center pieces of maple.

|

|

|

Here I'm running each piece through my

thickness planer. To prevent snipe, I made sure to keep each piece

butted against each other as they went through. With the aid of my

mobile work bench, this process worked out great.

|

|

|

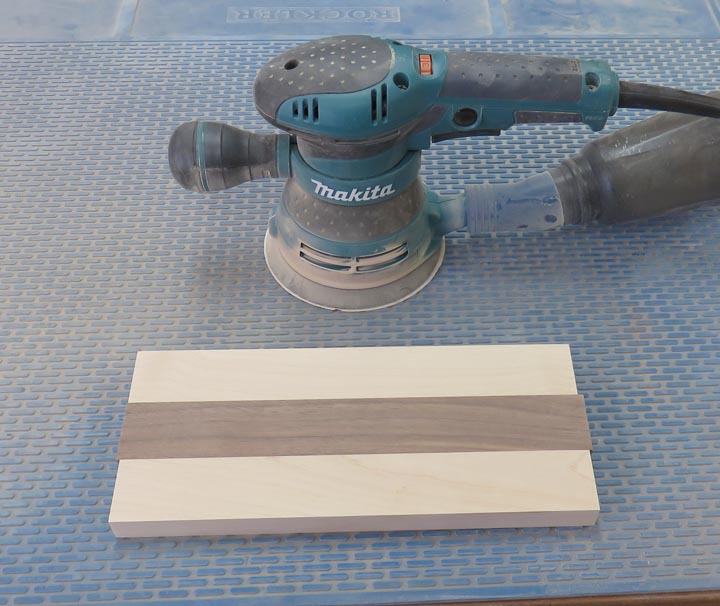

I gave each piece a light sanding using my DA sander.

|

|

|

First I ran all my pieces through my table saw bringing them all to the

final width. Then I used my crosscut sled to finalize the length. The

pieces measure 10" X 4.5"

|

|

|

|

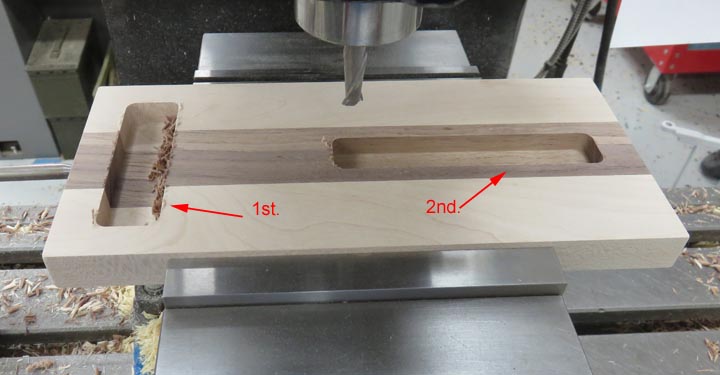

Now that I have my work pieces to size, it's time to

make a cut-out for the hammer to rest in. To prevent any chipping or

tearing with the end-grain, I cut the area for the head first. Then

second I cut the handle area. Last I cut the center for the smaller part

of the handle.

|

|

|

This process worked out very well and I didn't have any tear-out.

|

|

|

Each pocket is a different depth, which was easy to do.

|

|

|

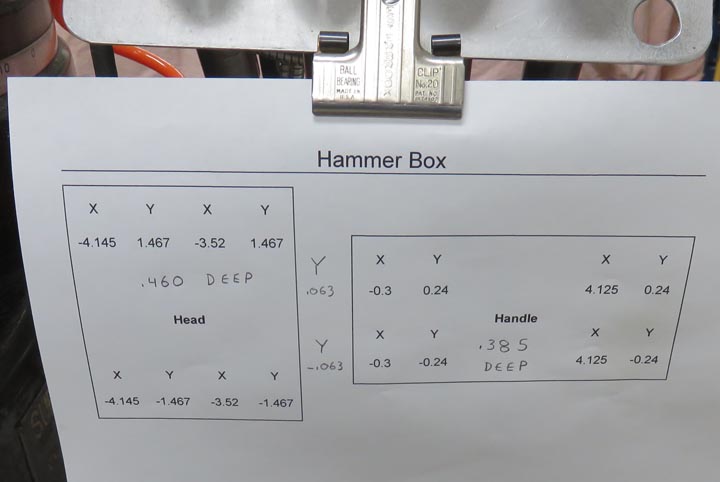

Here is my cheat-sheet for each pocket.

|

|

|

|

Working With Metal

Now it's time to install some hinges. I've never used

this exact hinge before but they are solid brass and are about 1/16"

thick. I have two choices of how I could install these: either on the

back or by making a pocket for each half on the inside. I decided that

they would look better if I made a pocket for each one, leaving only the

barrel of the hinge exposed on the outside.

|

|

|

|

After doing some closer looking and doing some

measuring, this was going to be harder to install that I first thought.

These hinges are kind of wonky, but I'm going to use them anyways. I

found out that when you close the hinge, there is a gap of about .050"

when the two halves are parallel. The cardboard piece on the right is about .050"

and I have a plan to use it.

|

|

|

|

1

2

3

4

5

6

7

8

9 |