|

Working With Wood Continued

To put the holes in my wood piece, I used my milling

machine. I first used a 7/32 drill, which is just under my target size

of 1/4". Then I came back with a 1/4" end mill to size the hole and to

give it a flat bottom. If I were to use a 1/4" drill for the final hole

size, the tip of the drill would not give me the maximum amount of

straight wall to locate the stainless pieces. I know it's not much of a

difference, but every little bit helps here to make sure things work

right. Over engineering? Probably!

|

|

|

|

Hanging The Rack

I talked to my daughter about how she wanted to hang

this rack on the wall. I mentioned a couple of different ways, like

picture hanging hardware but what we came up with was a 'key slot'. This

would keep the rack very close to the wall, which Tracey really wanted.

After I got off the phone with her, I went to the

hardware store and bought a key slot router bit. Now I've never used one

of these but I was willing to give it a try.

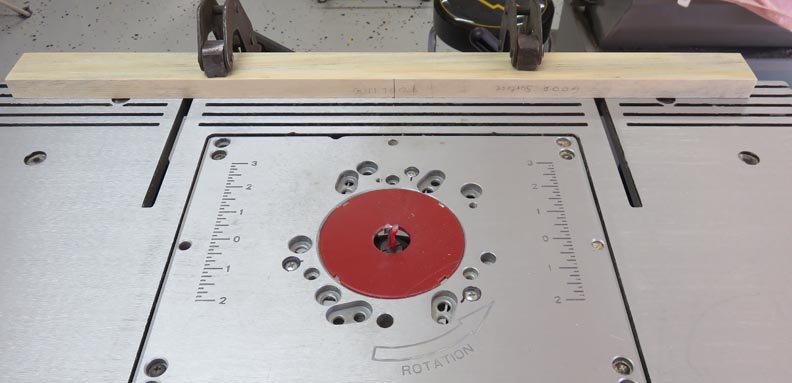

The piece of wood that you see clamped is where I'll

locate my work piece against to put the key slot in the center. Notice

the pencil mark that is in-line with the router bit. I'll use this as a reference

line that will correspond with two lines on my work piece.

|

|

|

|

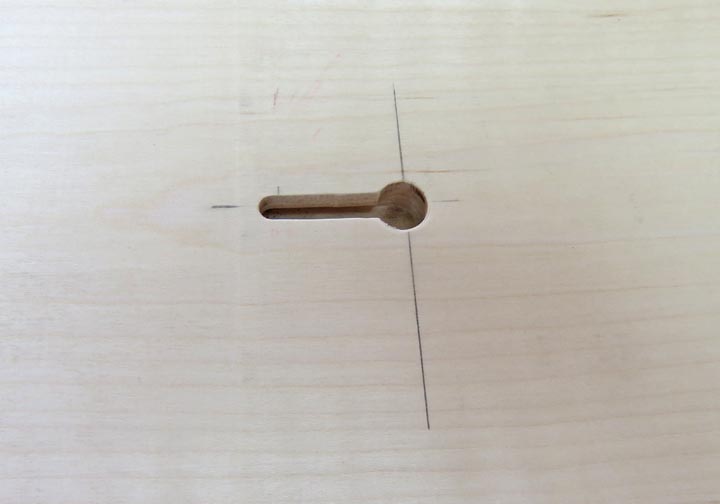

Here is what the key slot looks like on my work piece.

And it came out pretty close to were I wanted it. This was easy,

fast and definitely the way to go.

Now the rack will be against the wall like my daughter wanted.

The procedure: I started the router first, placed my work piece against

the wooden straight edge, lined up my mark and then lowered my work

piece onto the cutter. Once the work piece was flat against the router table, I slid

it one inch, slid it back to my starting point and then turned off the

router. The only tense part was lowering the wood into the cutter, but I

just think that was the hard maple being...well...hard. The reason I say

that is because I used a piece of pine as a test piece and it was very

easy compared.

|

|

|

|

Sanding Next it was time to sand. I started with 150 and then

went to 220 grit. Also notice I have my new dust collection attached

to my sander. Now this was my first time using my new dust collection on

this sander it made a BIG

difference.

|

|

|

|

I bought an adapter that goes from 4" down to 2 1/4"

that I attached to my mobile work bench (four screws). The hose

connections are all slip-fit so I can attach everything in seconds. And

the same goes for disconnecting as well.

|

|

|

|

I bought this dust collection system for my table saw

and planer but it works equally well for sanding. In fact, this was the

first time I didn't have sawdust all over my garage and can't wait to

use it again. Yes, it really does work that good and is a game changer

for me because normally, I have sawdust in and on top of "everything" so

this will make life much better.

|

|

|

|

It's "Semi" Finished

This isn't finished...yet. However, this should give you

a good idea of what it will look like. Tracey is going to add her touch

to the maple area but I don't know exactly what yet. So what I'm going to do

is send it to her like this, without any clear finish on it.

|

|

|

Once she does her magic, she'll put some clear polyurethane on it so it

will stay nice for years.

|

|

|

But before she does that she'll need to remove the stainless racks.

|

|

|

|

1

2

3

4

5

6 |