Once my 1/4" material was clamped in place, I removed the pin, placed

a short steel pipe over it and bent the rod to 90 degrees. The aluminum

shims and blocks are used so I don't damage my material while it's

clamped.

|

|

|

Once I had one side bent, I unclamped my

work piece, turned it around and repeated the process again. Doing it

this way I was assured that both ends were exactly the same length.

|

|

|

Here is the finished piece which was easy to do and didn't take very

long either. And both legs are the same length too.

|

|

|

|

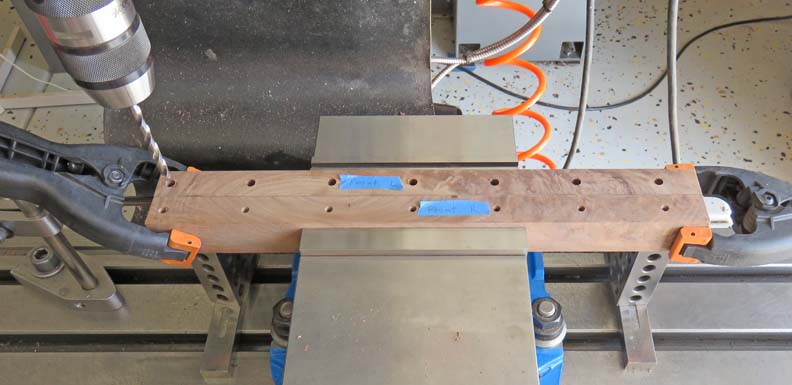

The next step was to drill some holes for the steel

racks. Tracey wanted them to be adjustable to I added a few holes.

Although I'm not sure if she will use these extra locations, it's

easy enough to drill them while I'm here. In the picture below you can

see the drill is sitting at what will become the bottom of the wood

pieces. That hole is 3/8" from the bottom and the rest are 2.5"

apart.

|

|

|

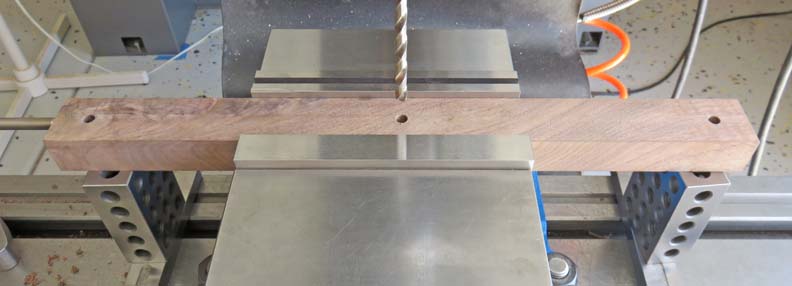

I needed a way to join the two wooden pieces together so I used more of

the 1/4" steel bar for this. I made sure not to have any two holes run

into each other while drilling.

|

|

|

Here is what it looks like with all of the holes in them. However, what

you can't see are the small screw holes that are on the back side, which

I'll talk about later.

|

|

|

|

Like I mentioned earlier, I'm going to use some of the 1/4" steel to connect the

two wooden pieces together. And to do that, I'll be putting some

small threads at both ends. The size of the threads are 6-32 and I'll be

using the digital readout to go from one hole to the next. Notice the

two clamps below. I've placed the clamps at each end of the rod to hold

them right next to where I'll be drilling. The number on the vice is the

distance between the threaded holes.

|

|

|

Here are the rods all finished and they came out pretty good.

|

|

|

Just a close-up of the small threads.

|

|

|

Here you can see what I've been talking about. I used some 6-32 flat head

cap screws to keep the rods from moving.

|

|

|

Here is a close-up of the flat head screws. These will be on the back

side of the rack so you won't see them. Now it's time to do some

painting.

|

|

|

1

2

3

4 |