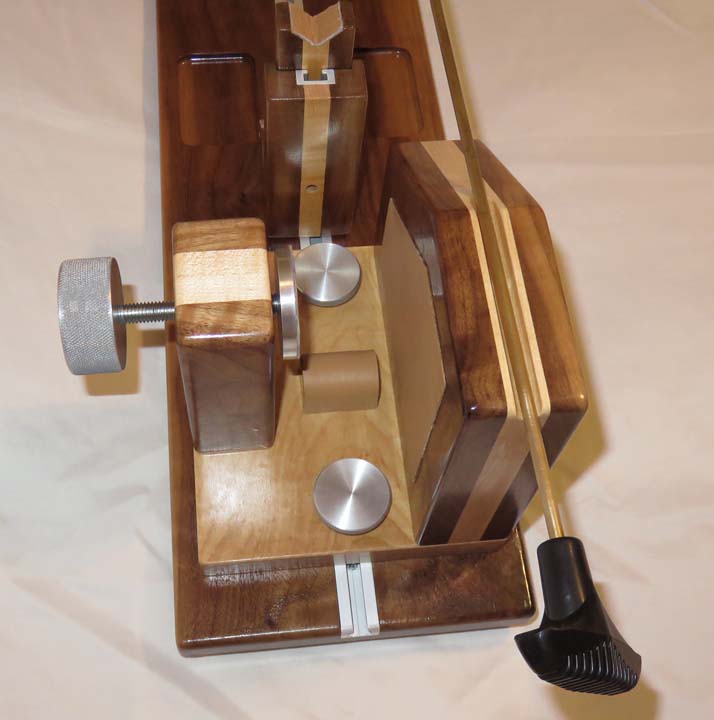

| When opened, it supports one end of my cleaning rod. The channel is

3/8" wide by 1" long and is made out of aluminum. The hinge has

been machined out of a solid piece of aluminum, which was fun to make.

|

|

|

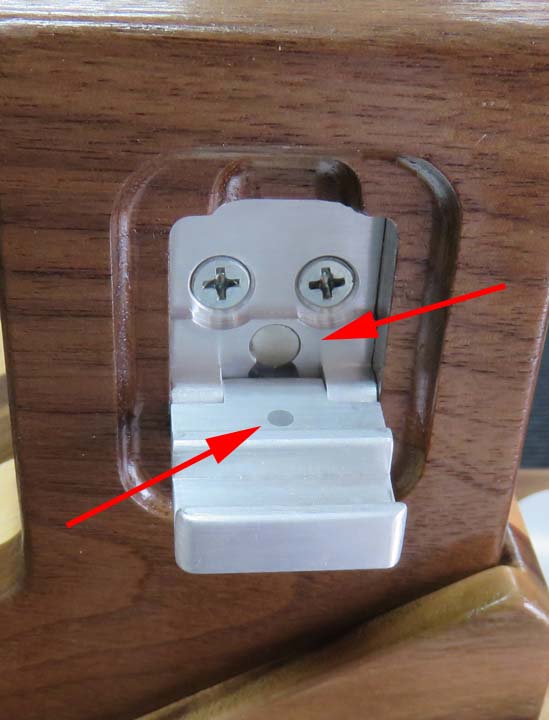

You can see the hinge better in this shot. The top arrow is pointing

to a 1/4" diameter X 1/16" thick magnet and the bottom arrow is pointing

to

a 1/8" diameter steel pin, which helps keep things closed when not in use.

|

|

|

|

To hold the stock without scratching it, I covered the round clamping

surface with leather. And the round clamping surface turns independent

of the knob to make sure it doesn't spin when it come in contact with

the gun stock. The way I did that was turn down the threaded end to .250

diameter X .250 long. I added a small groove near the end and used a

snap-ring to keep it in place. If you look close you can see a small

round area in the leather which has a .600 diameter pocket behind it.

The round piece between the two knobs is where a gun stock can rest.

It's been covered with leather and is removable. Note the round groove

in the stock support to the right, this is where the other end of the

cleaning rod will rest.

|

|

|

This piece has two dowel pins to slip fit into the base for easy

alignment. I made this piece removable in case I had a gun stock that

needed more clearance. These pockets should come in handy for small

parts and the large ones are able to hold the bolt from a rifle.

|

|

|

I made feet for the bottom and added some rubber washers for grip and

they won't scratch the surface it's sitting on. The rubber is held in

place with epoxy.

|

|

|

|

All the feet are adjustable with 10-32 studs that

thread into 1/2 long X 5/16 diameter aluminum inserts, which are pressed

in.

|

|

|

|

The slot in the stock support was made with a 3/8" ball

end mill and has a slight angle so the rod locates along the entire

surface. The rod angle changes when the V block is in different

positions of course but the angle I came up with works with my firearms.

|

|

|

|

The clear finish I used is a semi gloss made by

Zar and is their 'Ultra

Polyurethane'. It's an oil base product and I applied two coats with a

brush. After talking with a Zar rep, they told me this product was there

hardest drying and most resistant finish they sold. It was very easy to

apply and should take a few drops of gun cleaning solvent if I spill

some. I'm very happy with the results and will use it again on other

projects.

|

|

|

|

My brass cleaning rod ready to use and resting in

place.

|

|

|

|

The overall size is 34" X 7" X 3/4" thick. This

project was fun to make and I should get years of use from it. |

|

|

|

1

2

3 |