|

Using a Router Table

I want to put a radius around the perimeter on almost every surface so I

bought some router bits to help me with that.

I could have bought just one bit but I might do another project in the

future so the kit was the way to go dollar wise. I'll be using the 3/16"

corner round bit (I know it's called a 'roundover' bit in the

woodworking world, I'm just use to the lingo in the machinist world)

which should look nice.

|

|

|

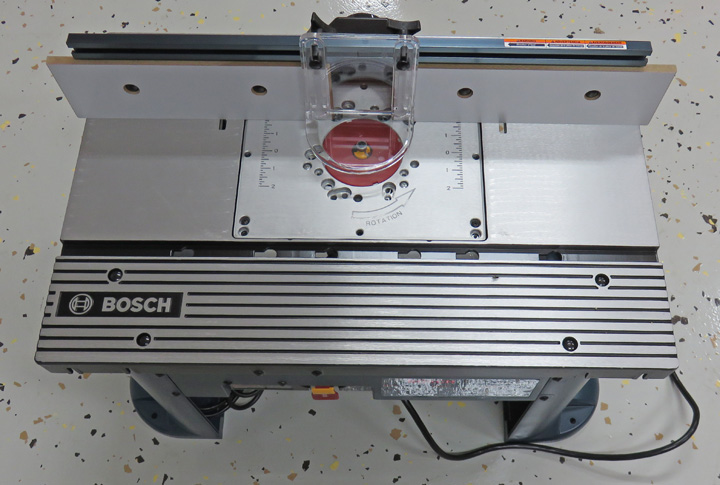

| Now I thought about using the new router bit in my milling

machine but that won't produce the high RPM that a router can so I

bought a table to mount a router in. Now this will be the first time

I've ever used a router table so this will be an experience for me.

I borrowed a router table made out of wood from a friend at work but

when I got it home I noticed the table had a big sag in it. I'm guessing

the sag was from the router being left in it over a long period of time

so I bought one with a cast aluminum table that shouldn't do that. It's made to except all

kinds of different routers which is why there are so many holes near the

center. I also don't know if this is a good, bad or middle of the road

table but if it works for what I want then it's all good.

|

|

|

|

The electrical switch controls two things, the router and whatever you

want to plug into the other receptacle, like a vacuum system for instance.

|

|

|

If you look close you'll notice the box is worn, like it's been sitting

around for years... seven I believe...damn...has it been that long?.

Well that's exactly what's going on here so let me explain: my daughter

Angela, bought this for my birthday and I thought it was a great

gift. But for some reason I've never used it....till now that is. Won't

she be surprised to know that I've finally used her gift to make her a

gift. Now I don't know if this is a good or a bad

unit, all I know is that it's a 'router' and I'm going to have fun with

it!!

|

|

|

|

After doing some reading about how the router works, the don't do this

and don't do that section, I made a couple of cuts on a scrap piece till

I had it adjusted like I wanted. After that I started on the base and

put a nice 3/16" radius on both sides.

The one thing I didn't want to do was climb cut with this router

table. Climb cutting is something I know about in the machinist world

and if you aren't careful, the piece you're cutting can get away from

you.

|

|

|

|

This router made short work of all the pieces and I'm

pretty happy with it so far. BTW, can you tell what I'm making yet?

|

|

|

I did have a small problem though, I had the cutter dig in a small

amount here and there and I think it's due to the fact that I had a

couple of pieces of maple that were warped. I knew about this earlier but

didn't expect this to happen. Well now I know and I won't make that

mistake again. On the plus side, this will sand out with no problem.

|

|

|

The next thing I'll be doing is milling a mortise and tenon. The tenon

will be on the upper part of the guys body which I rough sawed out

awhile ago. This will go into a mortise on the shield.

|

|

|

|

The other tenons will be on the bottom of our guy, for

his feet you might say. These will go into a mortise in the base. Again

these were rough sawed earlier.

|

|

|

|

I clamped an angle plate to my mill table and then clamped the sandwich

to the angle plate. I know it looks busy but this setup worked great for

cutting the tenons. Note the clamps are not in direct contact with the

wood. I placed shims between the two so the clamps wouldn't make any

marks in my work piece.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14 |