|

Making presents for the family is something I've done for a long time

now and I really enjoy doing it because I like seeing their faces when

they open them. The bank that I made Audrey was finished a month ahead

of time so I had some time to think of something else for her.

What I came up with was a small step stool for her to use while

washing her hands or brushing her teeth. However, after playing with the

design and then making a full size cardboard model, I added a little

something extra. The small step will do double-duty: it can be used like

you see below as a first step to the higher one, and it can also move

and become the back of a chair. Notice the small nail in the arm of the

step, this will be the pivot point. I'll add a non-movable stop for this

arm to rest against while in chair mode. This should be a fun project

and I hope to finish it before her big day.

|

|

|

Once I had my model and most of the dimensions for my

project, I went to

Reel Lumber in Riverside,

CA. to pickup some material. What you see here is some hard maple and

black walnut cut into their respective groups with tags on them so I

don't get too confused. Now it's time to start machining each piece.

|

|

|

The top of the stool will have both species of wood used that will

measure 8" X 12" when finished. Here I'm machining the sides of four

pieces that will be of equal size.

|

|

|

|

But one piece of black walnut will be of smaller size

that will go in the middle of the above step, which I'm machining here.

|

|

|

|

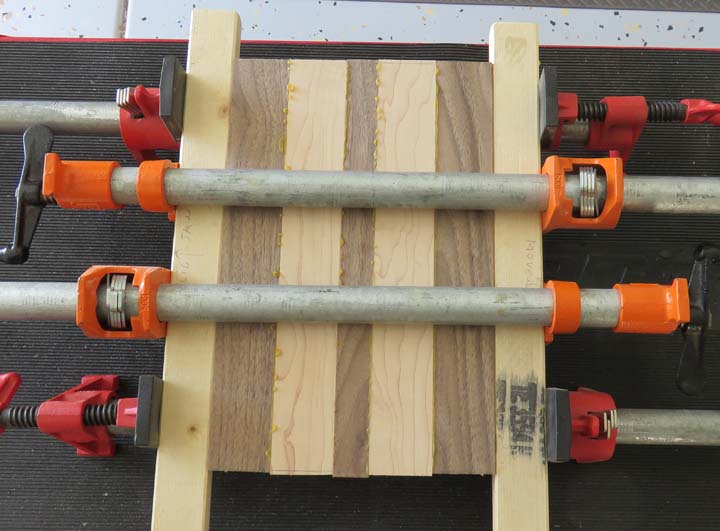

This should give you a better idea of what it will

look like. Note: the two pieces that are longer are not part of the

project, that are clamping aids.

|

|

|

I'll be using a solid piece of black walnut for each side, which is what

I'm machining here. By placing both of them in the vise and using some

clamps near the top while machining, this helps keep things from

vibrating because the work piece is tall.

|

|

|

|

This is the lower step or chair back. I went with more hard maple on

this piece so it would offset the amount of black walnut I'll be using.

|

|

|

|

I machined everything but the lengths, so that

will be next.

|

|

|

Machining wood is very easy and you can take some large cuts in doing so. However,

when you cut 'end grain' you need to use something to back it up with,

like the scrap piece that you see against the solid jaw. As the cutter

exits your work piece the rotation of the cutter wants to tear and split

the end of your work. But if you have something behind it (like

you see here) that won't happen.

|

|

|

|

Here I'm cutting the lower step/seat back on one end

only. The reason I'm not cutting it to length is because I don't know

what that length is...yet.

|

|

|

|

Here are the arms for the movable back, which

will be attached later. After they're in place I can measure from

one side to the other and find the length I need to machine the movable to.

Notice the long and short pencil lines on the bottom

arm. Those lines represent a 15 degree angle that will be machined

on them. Why 15 degrees? Why not!!

|

|

|

1

2

3

4

5

6

7 |