|

Here is the front of the orbiter and as you can see

there are thousands of tiles from nose to tail that we'll look at in

more detail later. The large and smaller openings that you see are thrusters

to maneuver the spacecraft while in orbit. These thrusters are on both

sides and are in the rear of the shuttle as well which I'll cover later

as well.

|

|

|

|

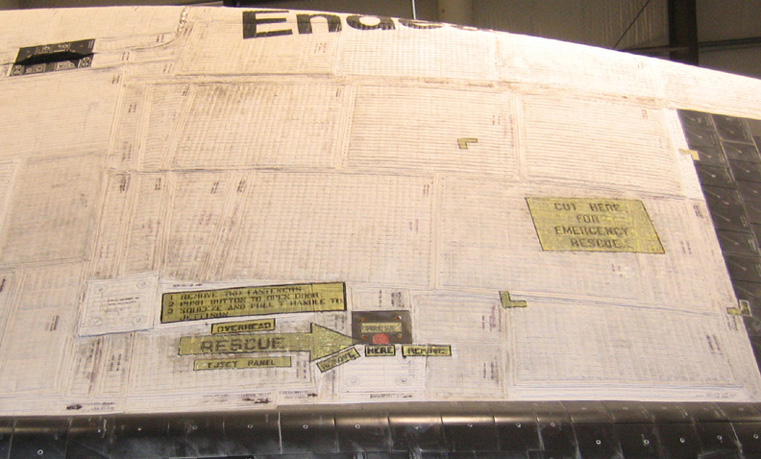

If you look close you can see the white area is made up

of panels that are about 3' X 5' in size. These panels are made of

Nomex felt blankets which is a flame resistant fiber developed by DuPont

back in the 60's. These panels can withstand temps up to 700 degrees

Fahrenheit. If you're into auto racing then this material is no stranger

to you because racecar drivers have been using it for their fire suits

for many years. All the big players in the space industry like

Lockheed Martin, Rocketdyne or NASA come up with lots of cool things that

are a necessity for them and then eventually they trickle down to the public, like Nomex

for instance. This material is also very light weight and is used to

fill in gaps between the cargo bay doors and other moving surfaces.

While we were walking around some guy asked us if we

wanted to touch the Shuttle. The guy had some small samples of material

that make up the outer layers that endure heat and one of them was Nomex.

The stuff is very lightweight and very strong. He also had a few other

materials that I'll talk about later. There are two

locations for rescue, one that says "cut here for emergency rescue"

to the right and

where the yellow arrow is pointing. In case you can't read the area

above the arrow it says; "1 remove two fasteners, 2 push button to open

door, 3 squeeze and pull T handle to jettison". Below the arrow says,

"eject panel".

|

|

|

|

Do you notice any thing strange or different about this

shot? Check out the flag because it's backwards. I asked about this and

the answer was, if the shuttle were moving and the flag was on a pole,

this is the direction it would be pointing.

|

|

|

|

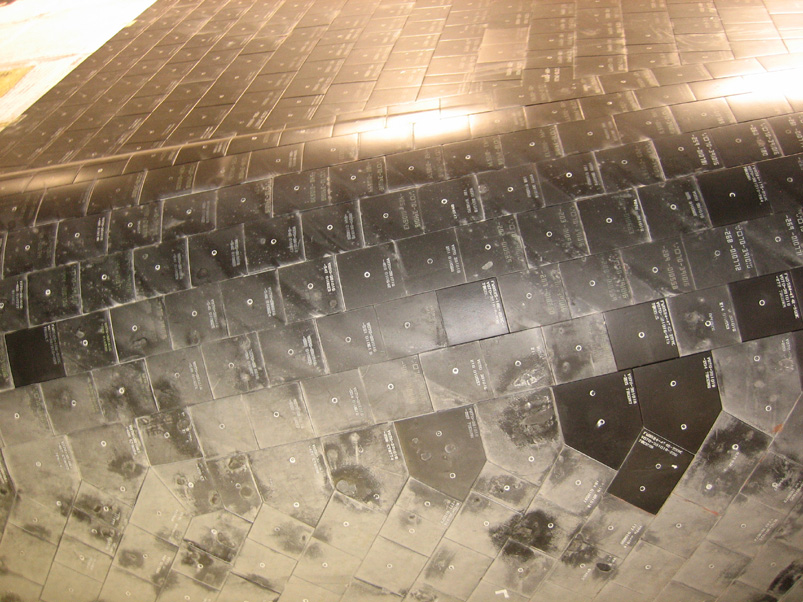

In this shot you can see some of the tiles and their

random shapes. Most of the tiles are 6" X 6" and vary in thickness from

1" to 5" inches depending on the heat load they encounter during

reentry. These tiles are referred to as High Temperature Reusable

Surface Insulation (HRSI). HRSI tiles provide protection

against temperatures up to 2,300 °F and there are over 20,500 of them.

The HRSI tiles are made of high purity silica fibers.

Ninety percent of the volume of the tile is empty space (air) giving it

a very low density making them very light. The uncoated tiles are bright

white in appearance and look more like a solid ceramic than the foam

like material that they are. The black coating on the tiles is Reaction

Cured Glass made up of several ingredients. Reaction Cured Glass was

applied to all but one side of the tile to protect the porous silica and

to increase the heat sink properties. To waterproof and to make them

more dense a special chemical was injected into them by syringe which

also helped to protect the silica and added additional waterproofing.

This was another one of the samples the guy let us check

out and they were very light. After holding one in my hand It's hard to

believe that something like this could take extreme heat like it does.

Truly amazing!

|

|

|

|

Here you can see the leading edge of the

wing and the lack of any tiles on it. That's because the tiles are behind

the light gray material called Reinforced Carbon Carbon (RCC). This

material is 1/4" to 1/2" thick and can withstand reentry temps of 2,750

°F which is also on the nose cap. The guy that had the random samples

also had some of this material and it was the heaviest of all. That

makes sense because the nose and leading edge of the wings would see the

most heat and would need the most protection.

RCC is a laminated composite material made from graphite

rayon cloth and impregnated with a phenolic resin. After curing at high

temperature in an autoclave, the laminate was pyrolized (which is a

thermo chemical decomposition of organic material at elevated

temperatures in the absence of oxygen) to convert the resin to carbon.

This was then impregnated with furfural alcohol in a vacuum chamber,

then cured and pyrolized again to convert the furfural alcohol to

carbon. This process was repeated three times until the desired

carbon-carbon properties were achieved.

To provide oxidation resistance for reuse capability, the outer layers

of the RCC were converted to silicon carbide. The silicon carbide

coating protected the carbon-carbon from oxidation. The RCC was highly

resistant to fatigue loading that is experienced during ascent and

entry. It was stronger than the tiles and was also used around the

socket of the forward attach point of the orbiter to the external tank

to accommodate the shock loads of the explosive bolt detonation.

|

|

|

|

The orbiter has wings that create lift. It uses a

double-delta wing configuration to achieve the most efficient flight

during hypersonic speed as well as providing a good lift-to-drag ratio

during landing. For control, each wing has an “elevon”. An elevon is a

combination of an elevator and an aileron like a normal airplane has.

On an airplane, the elevator controls the motion of

pitch (nose up, nose down). On most airplanes, the elevator is located

on the horizontal stabilizer as part of the tail section. Ailerons on

most airplanes are at the trailing edge of each wing and control an

airplane’s roll motion. Because of the orbiter’s delta wing

configuration, the elevators and ailerons are combined as elevons and

placed at the trailing edge of each wing.

|

|

|

|

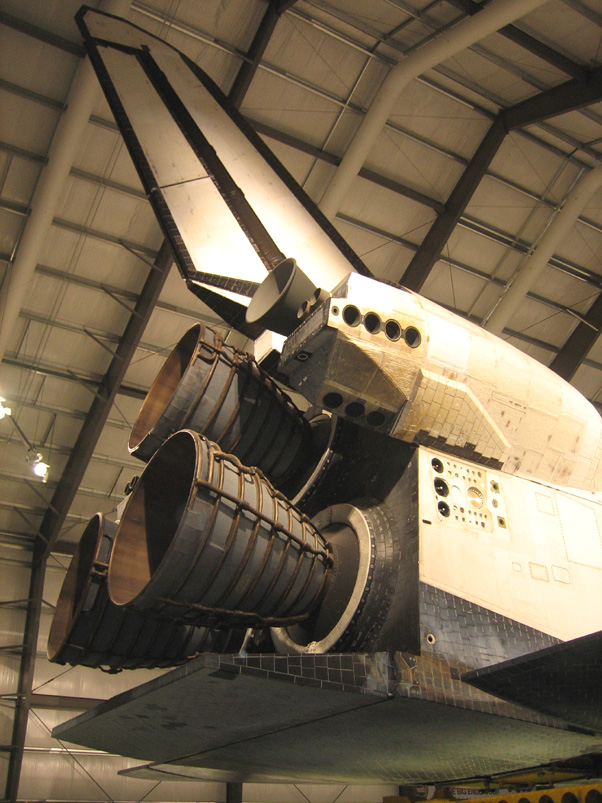

There is a lot going on in this shot so let's brake it

down section by section.

At the top you can see the vertical stabilizer or

rudder, which controls its yaw (nose left, nose right). The split rudder

on the orbiter works as a rudder and also as a speed brake (found on

most airplanes as a spoiler located on the wing). It does this by

splitting in half vertically and opening like a book. This deflects the

airflow, increases drag and decreases the orbiter’s speed once it's on

the runway during landing. Now the vertical stabilizer and elevons are

useless in the vacuum of space but once it re-enters the earths

atmosphere is when they work to help glide the shuttle to a safe

landing.

Below the rudder are some engines, three big main

engines and two smaller maneuvering engines. The main engines are

reusable and are the worlds most sophisticated rocket engines. These

main engines help propel the shuttle off the launch pad and into orbit

along with the two solid rocket boosters. The solid rocket boosters fall

back to earth using parachutes and are reusable.

The two maneuvering engines steer the shuttle and are

called Orbital Maneuvering Systems (OMS) engines which are located in

pods, one on either side of the tail. These engines place the shuttle

into final orbit, change the shuttle's position from one orbit to

another, and slow the shuttle down for re-entry.

Below the main engines covered in tiles is called a

flap. It provides a thermal (heat) shield for the engines during

re-entry and also provides pitch control (nose up and nose down) during

landings.

|

|

|

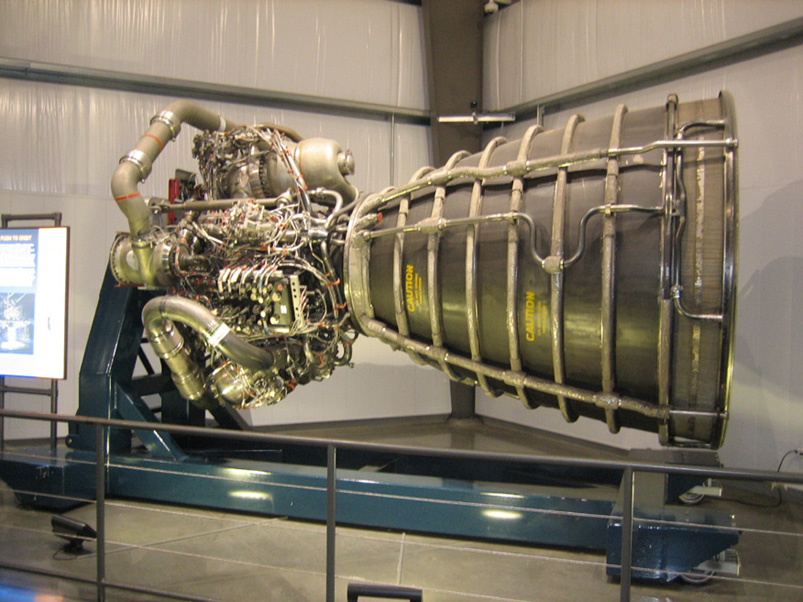

The main engines operate for about 8 1/2 minutes during

liftoff which is long enough to burn more than 500,000 gallons of

super-cold liquid hydrogen and liquid oxygen propellants stored in the

huge external tank attached to the underside of the shuttle. Liquid

oxygen is stored at –298 degrees Fahrenheit and liquid hydrogen at –423

degrees Fahrenheit. After these main engines shut down, the shuttle is

traveling at about 17,000 mph.

The OMS engines burn a solid propellant and nitrogen

tetroxide oxidizer. When these two substances come in contact, they

ignite and burn automatically (no spark required) in the absence of

oxygen. The fuel and oxidizer are kept in separate tanks, each

pressurized by helium. The helium pushes the fluids through the fuel

lines, meaning no mechanical pumps are required.

|

|

|

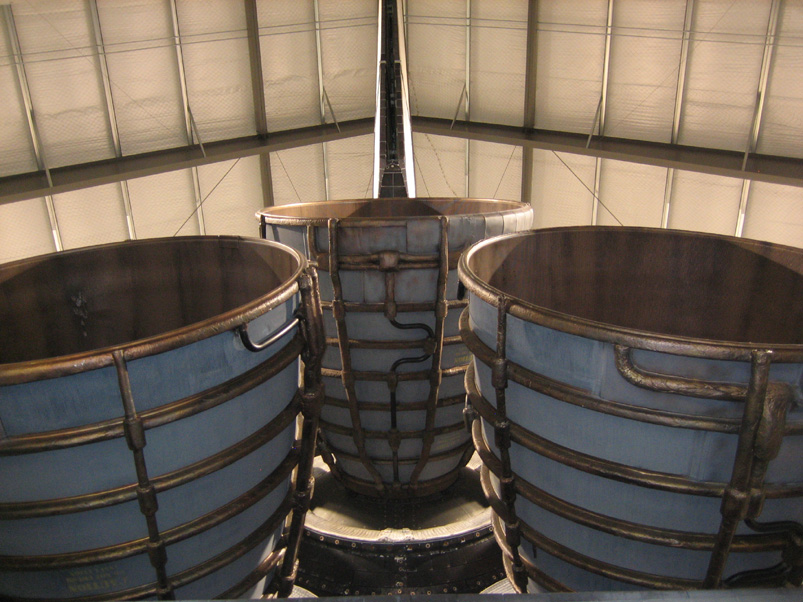

Each main engine weighs over 7,000 pounds and is 7.5

feet in diameter at the end of its nozzle. As they push the Shuttle

toward orbit, the engines consume liquid fuel at a rate that would drain

an average family swimming pool in under 25 seconds generating over 37

million horsepower with all engines working. The main engines are

gimbaled to provide pitch, yaw and roll control during the ascent.

|

|

|

Here is the RS-25 or space shuttle main engine (SSME) to

give you a better idea of what it looks like. I had to step back a few

feet because it's 14 feet long. It's built in the U.S. by a company

called Rocketdyne and after each flight the engines are removed from the

orbiter, inspected and refurbished before being reused on another

mission.

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12 |