|

Working With Wood Continued

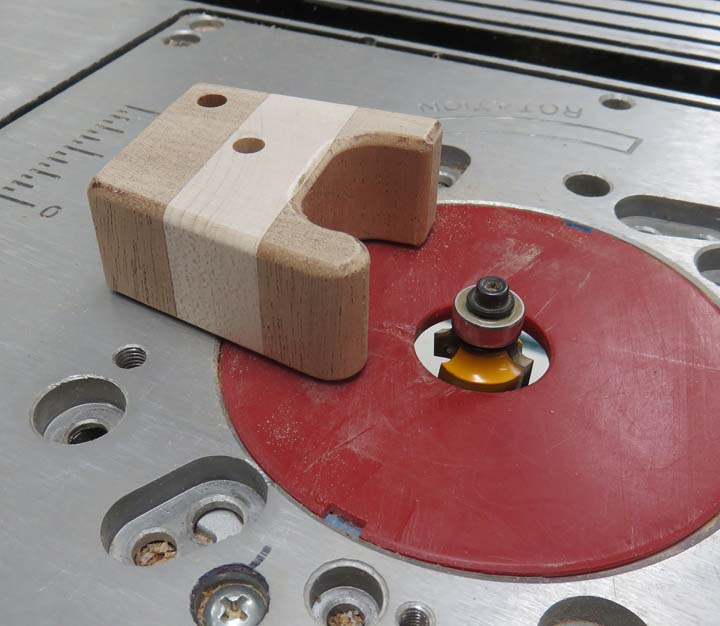

I used a 3/16 roundover bit to soften most of the edges.

|

|

|

Now it's time to glue and clamp all the

pieces together.

|

|

|

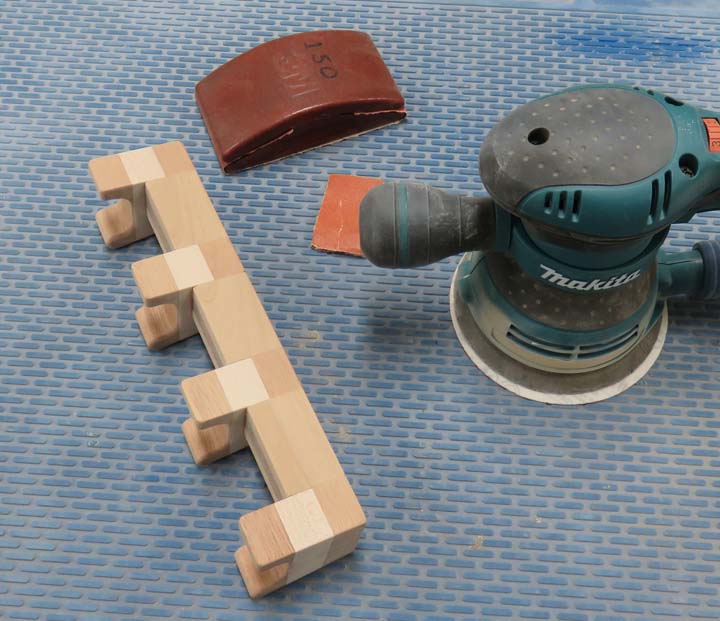

The next day I sanded the back and bottom with my DA sander. But the

rest of the edges were done by hand.

|

|

|

|

I bought some neodymium magnets from

K&J Magnets, to hold the

rack to a steel surface. The size of the magnets are 1" diameter by

3/16" thick and I'll be using two of them. The white plastic piece

between the magnets is how they were shipped, which makes it easier to separate them.

|

|

|

These magnets also have a countersunk hole so you can use a #8 screw to

fasten them with. I've used this style of magnet many times before and

they work great.

|

|

|

|

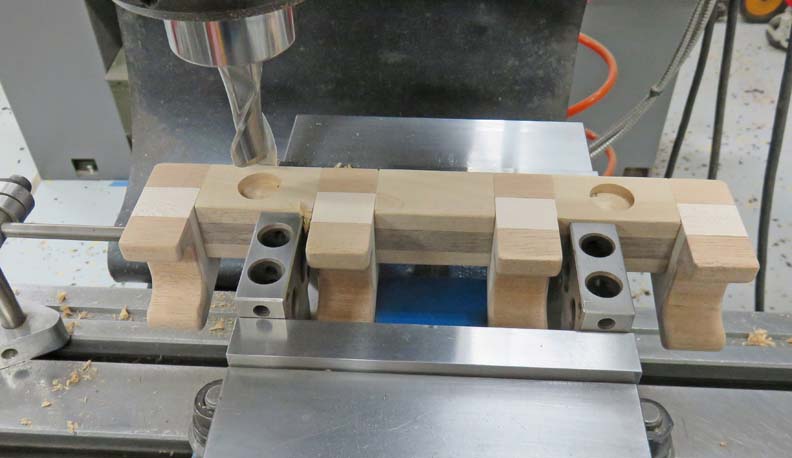

Here I'm using a 3/4" end mill to rough the pocket with.

Then I switched over to use my boring head to bring the pocket to size.

The reason I didn't use an end mill for this is because I didn't have

one

that size.

|

|

|

|

Once the pocket was finished, I drilled some pilot holes

for my screws. If you're wondering what those odd looking things inside

the pockets are, they are the dowel pins that I put in earlier. But this

won't affect anything because everything has been glued.

|

|

|

|

As I was removing the white plastic shim between the

magnets, one of them got away from me and found its way back to the

other one. The force created by the two magnets coming together was

enough to break them both into many pieces.

|

|

|

This all happened in a blink of an eye and there was nothing I could do

at that point. All I can say is, it's a good thing I bought four magnets.

|

|

|

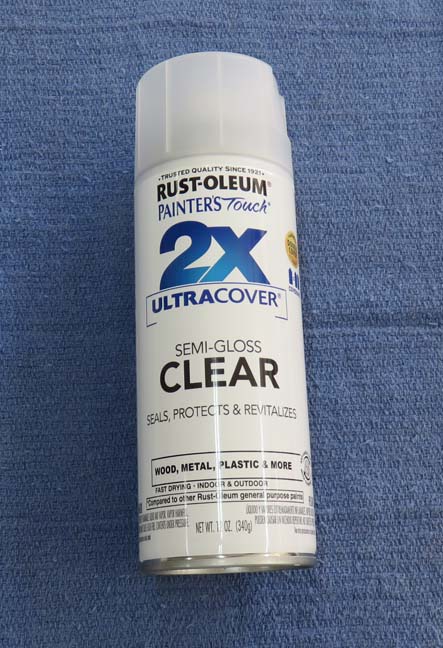

I'll be using some semi gloss clear on this project.

|

|

|

|

1

2

3 |