|

Lathe Continued

Here you can see the six inch, three jaw chuck. I

also received an eight inch four jaw chuck as well. You can see the

quick change tool post with a turning tool mounted in the tool holder,

which I'll talk about more later. Having a work light is very handy, and this one bends out of

the way or you can get it right next to your work. Also notice the air

hose right behind it, this is a must for metal working machines.

|

|

|

That small silver handle is to move the compound rest in and

out. This works great for turning a short taper of about three inches

long or less. This also works great for putting on a large chamfer that

excided the capability of your cutting tool.

On the tool holder there is a silver hex nut and below

that is a round

knurled jam-nut. These are for adjusting the holder up or down so your

cutting tool stays on center. Now this goes for all my tool holders and

is very handy when your

swapping tool holders with different cutting tools in each one.

|

|

|

Here you can see the dial that you turn to move the

compound rest. You can also set the tension so it moves easy or hard.

This can be handy for different kinds of jobs depending what you're

working on. And it also has an adjustable dial that makes cutting something very

precise

and repeatable.

|

|

|

Here is close up of the hex nut and jam nut. This is very easy

to adjust and it works great. And there are all different sizes of tool

holders that you can buy. All my tool holders are pretty small (compared

to the ones in the industry) but then again these all fit a smaller machine.

The largest tool this holder will except is 5/8" in height. I do have some that

will take a 3/4" tool but that's big for a smaller lathe like mine.

Here you can see the set screws that hold the tool

in place. I tighten all four screws to hold my tools.

|

|

|

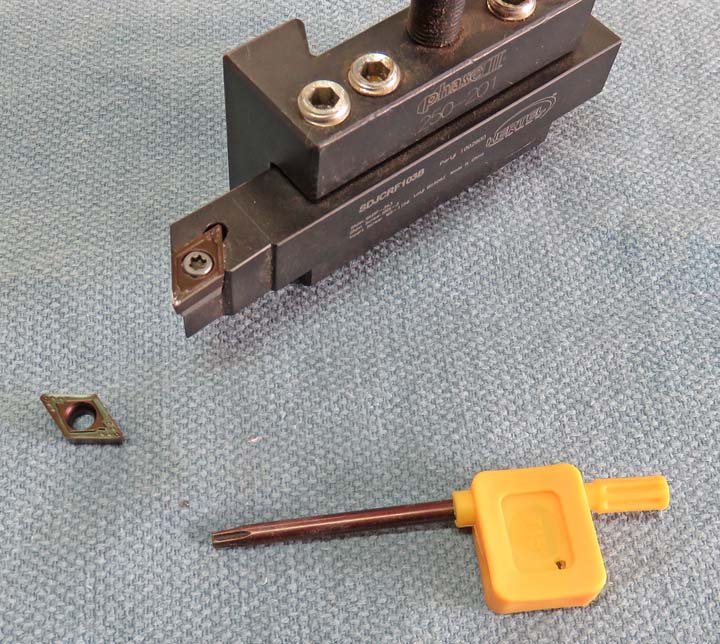

Here is a typical carbide insert tool holder. The screw

that you see in the middle of the diamond shape piece holds the cutting

tool in place. This cutting tool is made out of carbide and has two

cutting edges on it. Some carbide inserts have three or four cutting

edges depending on the style they are.

Changing inserts when they get dull is very easy. All

you do is remove that one screw, remove the carbide insert, blow out the

pocket that it sits in, turn the insert around and tighten the screw

again. At this point you would have a fresh cutting tip to work with.

Carbide inserts have a counterbore (or step inside them)

for the screw to locate on. This makes for a very positive lockup

system.

|

|

|

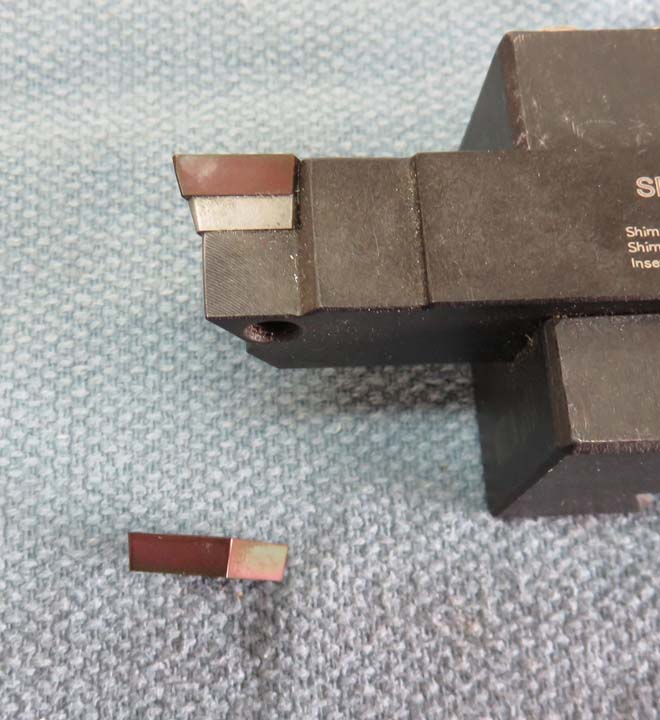

Here you can the rake angle on the insert. This one has

a positive rake angle and works great for finishing with. I also have

tools that except negative rake inserts, which work good for

roughing with. It just depends on what you're working on or how much

stock you're removing that determines what tool you will be using.

|

|

|

Here is the tailstock, which at the moment has a drill

chuck in it. The lever with the black handle is to tighten or loosen the

base. Once it's locked down, you can turn the round handle to drill

with. Or ream with, depending what's in the chuck.

|

|

|

|

Besides a drill chuck, I also have a live center. The

name "live center" means the pointed piece spins on bearings but the

tapered shank doesn't. Using a live center is very handy for supporting

your work while you're machining a longer piece. To use it you need to

center drill the end of your work piece first (using the drill chuck)

then switch to the live center and insert the tip into the center

drilled hole. My live center has a 60 degree angle.

Side note: Center drills come in many different angles

besides 60 degrees. That means you need to be careful when using a live

center, making sure to use the exact same center drill angle so they match.

|

|

|

One the back side of the tail stock is a smaller handle

that locks the quill so it won't move. This is very handy when you're

using a live center for instance.

|

|

|

1

2

3

4 |