| The router wasn't able to get into the

corner so I had to work this area by hand.

|

|

|

I used a scrap piece of wood as a sanding block which worked great for

this. And it went quickly to.

|

|

|

|

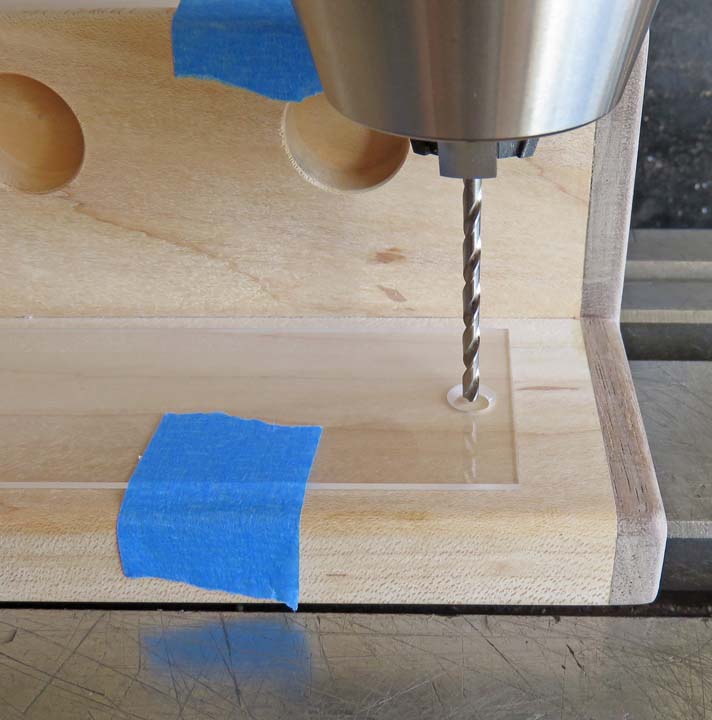

The next thing I'll be working on is some clear plastic.

I plan on printing out the information for each piece of material and

I'll use this plastic to cover it with, like a plaque would have. At first glance

it looks like I'm machining the wood here. Actually the wood is being

used as a clamping aid, which is helping me hold down the plastic (arrows).

|

|

|

|

I'll be using three screws to hold the plastic down.

Here I'm drilling the holes for the screws. After drilling I chamfered

them all for flathead screws. I drilled the ends first and then moved to

the center. I did this for both pieces of plastic.

|

|

|

I placed both plastic pieces exactly where I wanted them and held them in

place using tape. Once they were in position, I drilled the screw holes.

|

|

|

|

Once the holes were drilled, I screwed them in by hand

to make threads in the wood. And wouldn't you know it, two of them broke

off while I was doing this. Now I know better than this because these

screws are made out of brass. What I should have done was

use a screw made out of steel to prevent this from happening. I had to drill them both out

on my milling machine and then re-thread them. This didn't take long but

could have been avoided.

|

|

|

I sanded everything with 180 and then 220 grit

paper.

|

|

|

A close up of the base before I put a finish on it.

|

|

|

|

This is a piece of titanium that got from my work

that started out as a large ring. It

was a scrap piece that I had to machine square first and then I turned

it on a lathe. I used a three jaw chuck to turn it with and as you can see I

didn't have much room for error while doing this. I did this for

all the irregular shaped pieces and once everything was the correct size

and length, I was ready to weigh them all.

|

|

|

|

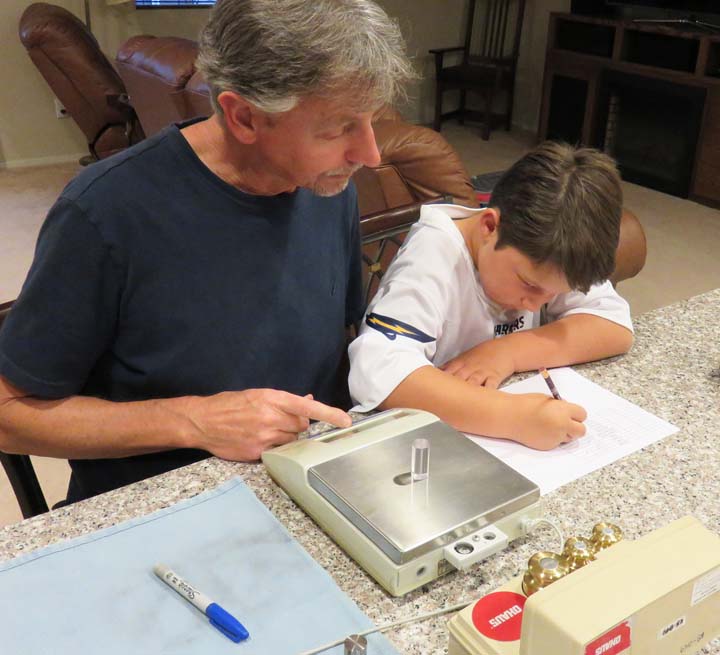

One evening when Aidan and his mom, Stefanie came over

for dinner, I had my grandson help me weigh each piece of material. The digital scale

that you see below came from my work and is very accurate. As we used it, I had Aidan write down how much each one weighed (in grams).

The piece on the scale is copper.

|

|

In the foreground you can see a box of brass 'standards'. These

standards get

calibrated each year and are used to verify that the scale is weighing correctly.

The piece on the scale is plastic.

|

|

|

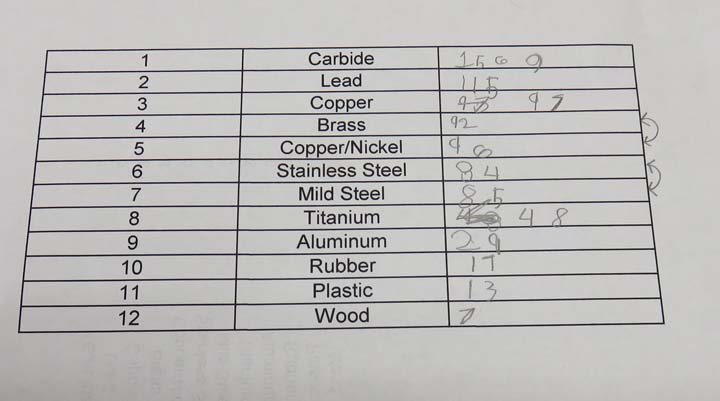

I printed out a list of the materials that I'd be using

and you can see Aidan has written down all the weights. I guessed at which one would be the heaviest to the lightest

and I came

close but I had to switch two of them around (arrows). As we weighed all

the pieces I wrote it's corresponding number on each one using a felt marker.

The reason for this is because I wouldn't even know the difference between mild steel and stainless steel

if they were placed side-by-side. Yes, those two metals really do look

the same.

|

|

|

1

2

3

4 |