|

Precision

Vises 1

10-2018

|

What you see below has been many years in the making....let me explain: I've

been a machinist all my life and I've made a lot of tools for

myself over the years. And just so you know, these tools that I make are

to help me while doing my job as a machinist. Now one of the tools that

I've always wanted to make was a 'precision vise', which is what I'm

making this time. However, there's a back-story that goes along with

this project, which is where I got the idea in the first place.

I started working for my current employer way back in 1983. Yes you

read that right, I still work for the same company after 35 years of

employment. But I started my machinist career in 1974, right after

graduating High School. Anyways, in about 1985, my work received a contract to make

some test specimens for an aerospace manufacture. This aerospace

manufacture was a very large well known company back then and they

supplied us with a bunch of steel to make these parts out of. Now this

material was very good stuff, which was 4340 steel, and it came to us in

round bar and square stock of all different sizes. My job was to make a

few test specimens out of each piece of this material, which was not

that big a deal. However, we ended up with a bunch of leftover material

and that big aerospace company didn't want it back.

Well this worked out pretty good for me because after looking at all

this extra steel laying around, I could envision a vise or two that

could be made from it. With the largest piece of of this leftover steel

being about 6" square by 15" long, this had a nice large precision vise

written all over it. And with some of the smaller chunks being 4" square

by 16" long, that put the idea of two smaller ones in my head as well.

A couple of months went by and I started cutting up this material so I

could start working on it. And as luck would have it, we had some slow

times in the shop back then so I took this opportunity to work on my new

vises. After a few months had gone by, I had my vise bodies roughed

out but for some reason I never did rough out the vise jaws. However, I

did cut the material for the jaws, squared them all and then stuck it my

toolbox hoping to work in them again soon.

Slowly the years went by and my new project became a distant memory.

But every now and again I would be reminded of my old project when I

would open the bottom drawer to my toolbox. Why you ask? Because this

bottom drawer was really hard to open with all that weight in it.

Fast-forward to December of 2017, Christmas time to be exact...this

is when my work closes down for the holidays (for at least a week). And I

like to take an extra week of vacation time during this time of year.

Well for some reason I used this down-time to work on my old project, It

was like they were calling me! And during that time off I got all three

vises ready for heat treat. However, while working on this project

(during my time off), I didn't take any pictures, except for the one

below. Yeah, yeah....I know....sorry.

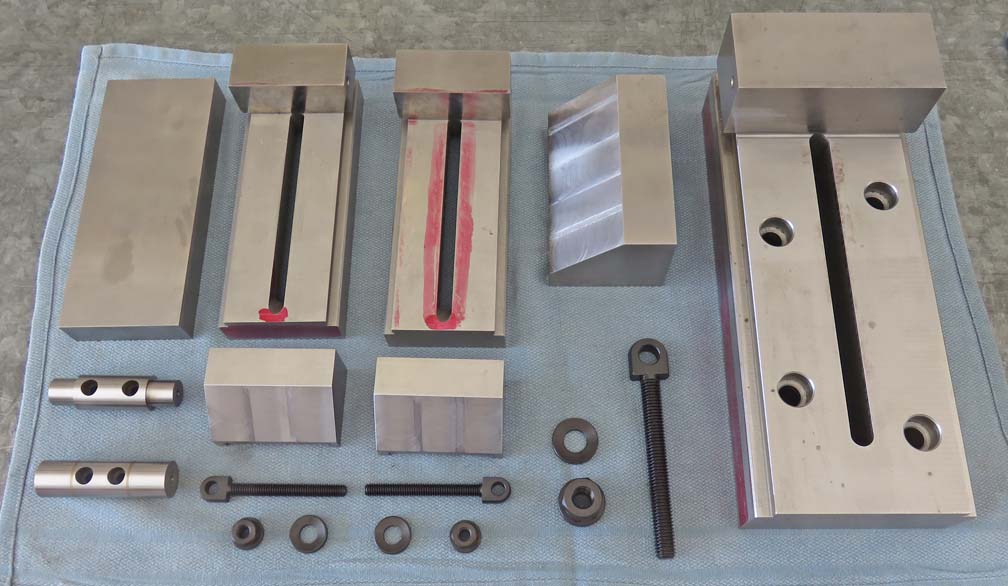

One more thing, when I took the picture below, I still had a long ways to

go before anything was ready for heat treat. I mean, just look at the

jaws, they don't have any holes in them, along with many more details

that need to be done first. Yes, I should have taken my more pictures

along the way but I got into 'high gear' and didn't even think much about.

Oh...I almost forgot, I'll be making two smaller vises. Why two? One of

them will be a 'sine vise'.

|

|

|

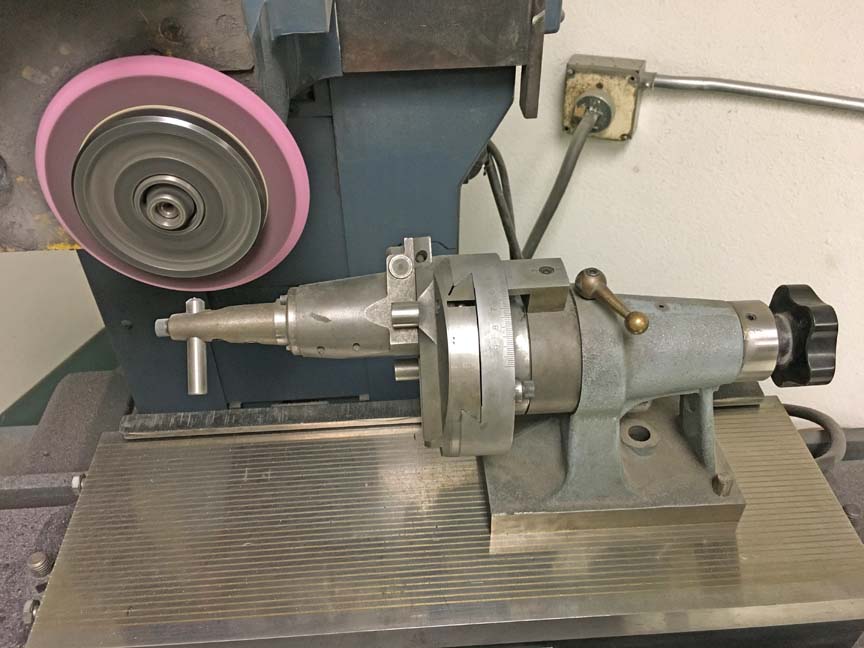

| But wait, what's a sine vise? A sine vise sits on two

cylinders (below), with one cylinder being the hinge (right) and the other is

placed at a precise distance from the other. The hinge (or axis of

rotation) needs to be very precisely made, with no slop in it what so

ever. If you look close you can see it's made from multiple pieces. I

used brass between the each piece because everything has been hardened.

In fact, I made these pieces back when I first started on this project,

but

they are not made from the same material as the vises. These two pieces

are made out of oil hardening tool steel and I ground them on an O.D. / I.D

(outside diameter / inside diameter)

grinder. However, that grinder is long gone now so I'm glad I was able

to finish them before my work sold it.

The larger holes are for cap screws, which are used to hold them to

the vise body. And the smaller holes on the hinge are tapped 1/4-28 and again

are used to hold them to the vise. I'll talk more about the step that

you see on the solid piece in a bit.

|

|

|

|

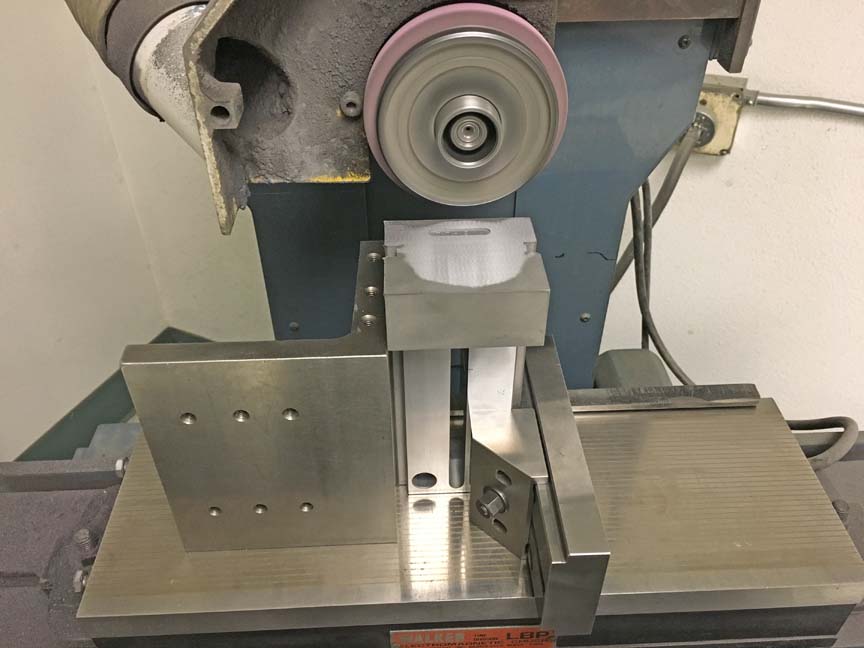

I've got all the pieces back from heat treat and now it's time to grind

everything. What you see below is a surface grinder, which is a

precision grinding machine that uses a magnet to hold your work piece

from moving.

In this case, our work has a Jones & Shipman surface grinder with an

electric magnet. An electric magnet works great and if you need to vary

the amount of magnetism, you can that too. Here I'm grinding the end

of the smaller vise and making it square to one of the sides. To unsure

that your work piece comes out square, you grind two surfaces before

removing your work piece (in this case, one side and one end). Once

those are cleaned up, you remove your work piece and place either one of

the newly ground surfaces on the magnet and grind it, making it parallel

to the opposite surface. This step is essential and has to be done right

or you end up with something that is just...well...close. However, close it not

good enough when it comes to a precision vise, it has to be done right!

You can see below that I have a little more material to remove so it has 100%

cleanup. It's funny but I'm using another precision vise to grind my

precision vise with. BTW, surface grinding is a very slow process and

takes time if you want things to come out right.

|

|

|

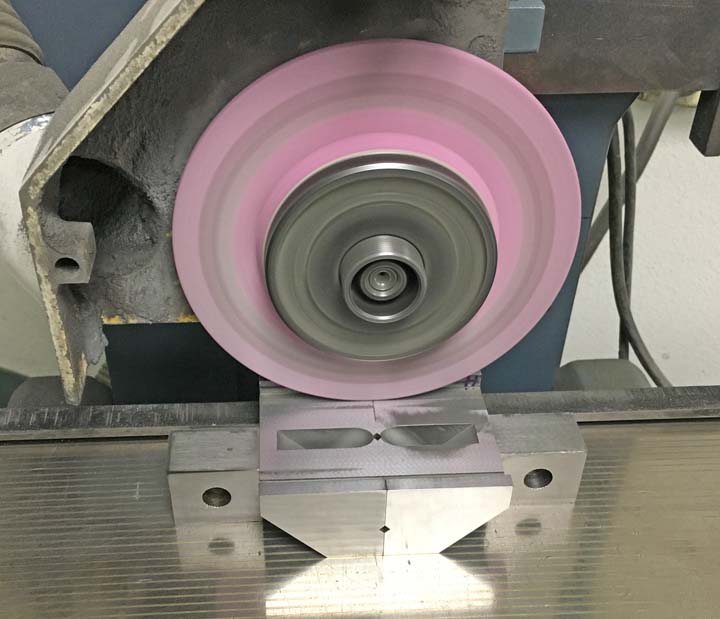

Here I've changed grinding wheels and now I'm working on the movable

vise jaws. I'm grinding both at the same time and once I have them both

cleaned up, I'll measure them and grind the vise body to fit. Note:

I've dressed the wheel so the sides of the wheel are not parallel with

each other. Instead I left the outer portion of the wheel a little

larger than the rest of it so the outer edge only does the work. With

the grinding wheel dressed this way, it cuts more freely on the sides

with less chance of any problems while working on the inside locating

edge of the jaw.

|

|

|

|

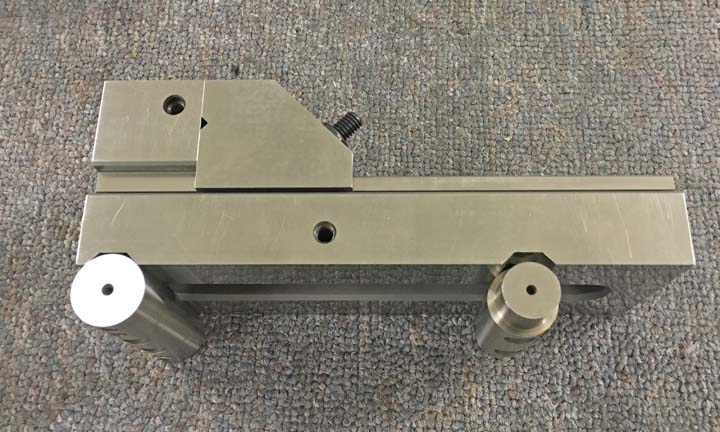

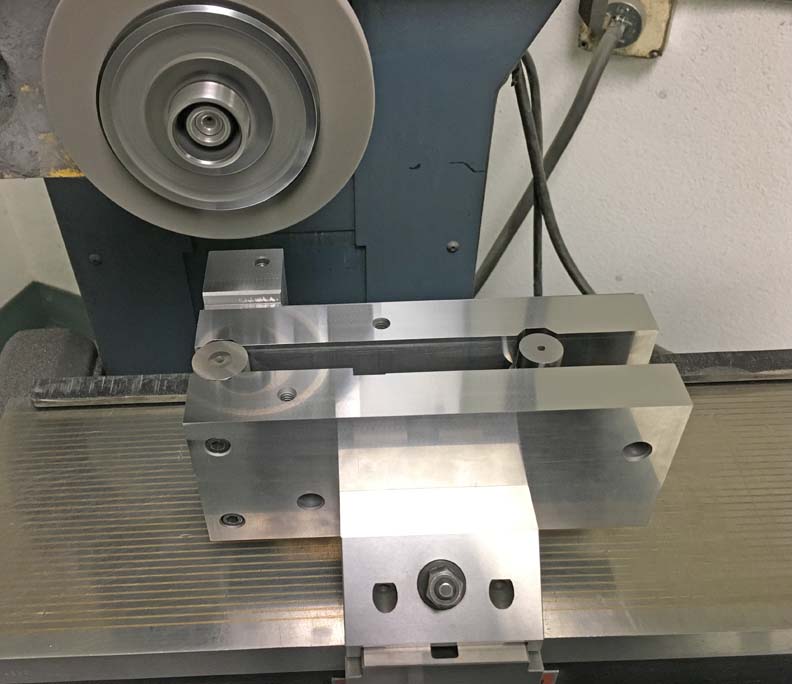

I made these two cylinders a little long years ago so

now I'm removing .010 and .015 from them so they fit right. I'm

holding them in a V block and backing it up with a pair of 1" X 2" X 3"

blocks. Side note: I made both of these tools a long time ago (V blocks

and 1 X 2 X 3 blocks) and they

have come in very handy over the years.

|

|

|

Here I'm test fitting the two cylinders to see how they fit. After

measuring them, I needed a few more thousandth's to come off of each one

so they would end up just below the sides of the vise body.

|

|

|

Now that the jaws fit vise body, it's time to grind in the V's that I

put in the movable jaws. The V's in the jaws are to hold small diameter

pins, or some other kind of small items. And what you need/want is for

the V to be right in the middle of the jaw when your finished. Here I'm dressing the wheel

at a 45 degree angle (both sides) and then I'll be able to work on the

jaws.

|

|

|

Here you can see the V that I'm working on. This is a slow process because after making a 100% cleanup on

the V, I have to remove the vise that's holding the jaw, then remove the jaw, install it on my

new vise body, place

a pin in the V, tighten the vise so it clamps on the pin and then

measure the pin with an indicator from both sides of the vise to see how far it's off

center. Once I have a number of how far it's off, I clean everything

very good, place my jaw back in the vise and grind a small amount of

material from the V. Then

I repeat the process above to check my progress again.

|

|

|

A close-up view of the V and grinding wheel. This process took about 45

to 60 minutes per jaw but it came out right where I wanted it. BTW, the other V that runs 90

degrees to this one didn't take long at all to grind because all it

needs to be is cleaned up.

|

|

|

|

Here I am doing some final grinding on the sine vise.

|

|

|

|

1

2

3 |

|