Memory Lane 2

5/08/06

| The plaques are made by a process

called "casting" which means pouring molten aluminum into a

mold that has a reverse pattern of what you want in it. Once the

aluminum cools, you open the two halves of the mold to reveal the

finished piece. I'm going to be painting my plaque the same color as the

car but there needs to be a little prep before I have Bart, my paint

guy, spray anything.

The cast surface is a little rough right now so

the first thing that needs to be done is some sanding. I'm going to sand

the whole thing except the recessed area that looks like it has a bumpy

surface on it. That bumpy surface is going to be painted along with the

sides and back. The front is going to be sanded again after paint to

reveal a nice brushed aluminum finish which will contrast well with the paint.

I used 120 grit paper on my sanding block to get

the top surface nice and flat. Once this surface is flat, it will be

easy to come back after paint and re-sand it along with the border. I

also sanded the sides and back nice and flat because once it's mounted

in the car, I want it to look nice.

|

|

|

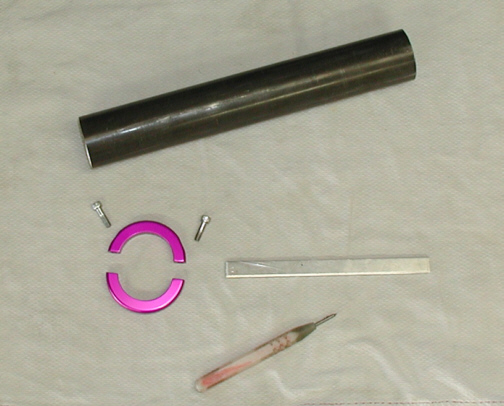

| To mount the plaque inside the car,

most people have a package tray to use but a 33 Ford doesn't have one.

That meant I had to come up with another method of installing it.

The rear window is only a few inches away from the roll cage which

gave me an idea. What I

came up with was to use a leftover roll bar clamp and hang it from my

cage. This clamp (purple piece) was originally used in my trunk to hold

my gas springs to the roll cage, one on each side, but that didn't work

out. I ended up using one of the two clamps to hold a prop-rod in place

of the gas springs and the other one went into the a parts box.

Remembering this clamp wasn't being used anymore, I thought I could

bring it back out of early retirement and put it to use.

What I had in mind was to use the

clamp along with a bracket to hold the plaque in place. The piece of

aluminum that you see below is going to be my bracket. It measures

1/2" X 4" X 1/8" and will have a hole on one end that

will be attached to the roll bar clamp and the other end will have two

holes that will go to the plaque. I brought out a piece of roll bar

tubing to fit the clamp because it's much easier on the bench than in

the car.

|

|

|

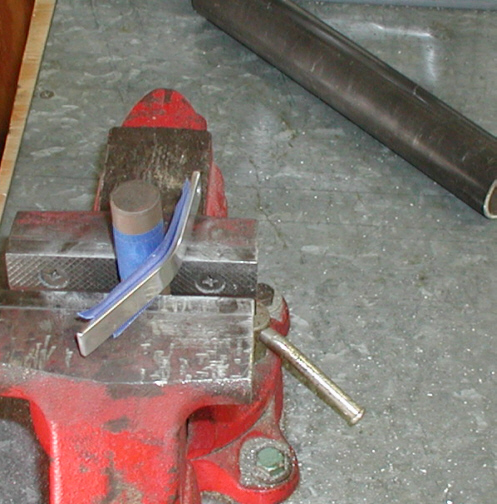

The first thing I did was drill a clearance hole for

the clamp screw and then polished the piece of aluminum. I made sure that

the bracket fit right up against the roll bar tubing so it wouldn't move

side-to-side because this end only has one mounting screw. Once that was

done, I put a small bend in the bracket so it would sit at the right

angle. To prevent the surface from receiving to many scratches, I put a piece

of tape on it first and then bent it. To bend the bracket, I just used my

hands till the angle was where it fit right.

|

|

|

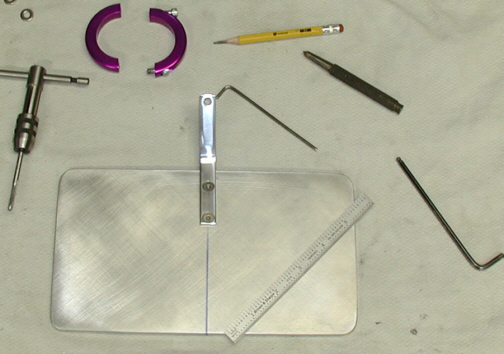

To hold the bracket in place, I drilled and tapped the plaque

with 8-32 screws and then made transferred two clearance holes too my bracket. The

screws are stainless flat head cap screws that are countersunk flush. This

should be a nice contrast when the plaque is painted.

|

|

|

|

1

2

3 |

|